Expanded Mesh Panels for Real-World Projects: Notes from the Shop Floor

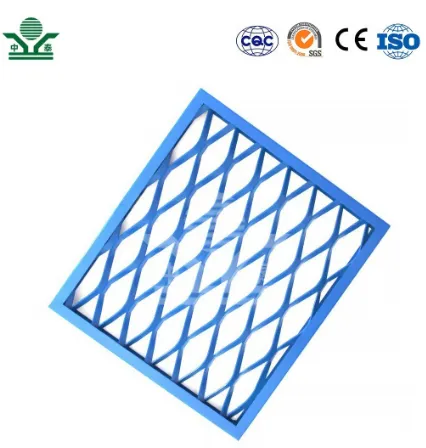

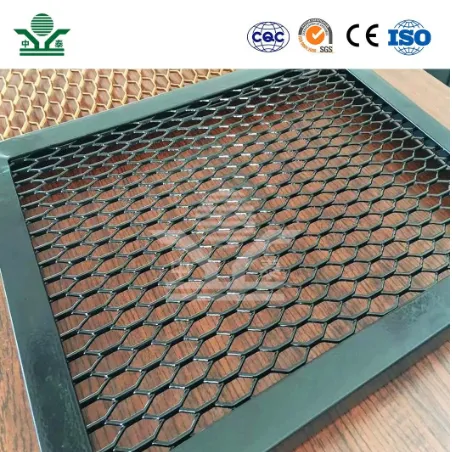

If you’ve been watching façade and safety specs lately, you’ve seen the surge in Expanded Mesh Panels. To be honest, the appeal is obvious: one solid sheet, slit and stretched into diamonds—strong, airy, and surprisingly beautiful. I’ve toured lines in Anping where the rhythm of expanders is almost musical; quality, however, comes down to steel grade, expansion ratios, and the spray finish chemistry.

What’s inside “Sprayed Expanded Metal Mesh”

ZT Wire Mesh (Anping, Hebei) runs stainless plate—typically 304/316L—then expands, levels, and spray-coats. Their sprayed finish (polyester, PVC, or FEVE/fluorocarbon for tough climates) gives Expanded Mesh Panels the UV and corrosion resistance architects quietly obsess over.

| Spec | Typical Values (≈) | Notes (real-world use may vary) |

|---|---|---|

| Base Material | SS 304 / 316L (ASTM A240) | 316L preferred near coast |

| Thickness | 0.5–3.0 mm | Heavier for catwalks |

| SWD / LWD | 10–100 mm / 20–250 mm | Diamond opening set by die |

| Strand Width | 0.5–6.0 mm | Controls strength & openness |

| Open Area | 35–70% | Affects airflow, shading |

| Coating | 60–80 μm polyester / PVC / FEVE | ISO 2808 thickness control |

| Service Life | ≈10–25 years (C2–C4) | Exposure & maintenance matter |

Process flow (how the sausage is made)

Materials: stainless steel plate per ASTM A240. Methods: slitting and expanding (ASTM F1267), flattening/leveling, edge trimming; spray application and curing at ≈180–200°C; QC—adhesion test (ASTM D3359), salt spray (ASTM B117/ISO 9227), thickness (ISO 2808), impact (ASTM D2794). We’ve seen 720–1,000 h neutral salt spray on FEVE-coated sets—respectable for coastal car parks.

Where Expanded Mesh Panels shine

- Architectural facades, sunscreens, stair enclosures

- Protective guarding, machine cages, security partitions

- Filters and sieving (diversified pellets), barbecue mesh (yes, really)

- Walkways and platforms (spec heavier strand width)

Many customers say airflow and partial sightline make it a sweet spot between privacy and ventilation. I guess that’s why parking structures keep picking it.

Vendors: not all meshes are equal

| Vendor | Strengths | Lead Time | Certs |

|---|---|---|---|

| ZT Wire Mesh (Anping, No. 12 Jingwu Rd.) | 304/316L focus, FEVE option, tight SWD/LWD control | ≈12–20 days | ISO 9001; coating per RoHS/REACH |

| Importer A | Stock colors, low MOQ | 3–5 days ex-stock | Varies, ask for D3359 report |

| Local Fabricator B | Custom frames, site measurement | 2–4 weeks | Project-based QA |

Case notes (quick hits)

Retail façade, humid subtropical coast: 316L + FEVE, 70 μm; salt spray lab result 1,000 h; on-site after 18 months—no chalking, fast install due to lighter subframe.

Food plant screening: 304 + polyester, 60 μm; daily washdown; D3359 adhesion 5B at FAT. Operators liked the airflow; maintenance flagged fewer lint traps than perforated sheet.

Testing snapshots

- Adhesion: ASTM D3359, 5B on recent lots

- Salt spray: ASTM B117 / ISO 9227 ≥720 h (FEVE sets)

- Coating thickness: ISO 2808, 60–80 μm typical

Bottom line: specify the metal grade, SWD/LWD, strand width, and coating system together. For procurement, many teams shortlist Expanded Mesh Panels from ZT Wire Mesh’s Sprayed Expanded Metal Mesh line out of Anping (Hebei, China) for the balance of price/corrosion control—and yes, the address is easy to remember when you’ve actually been there.

Certifications and documentation to request

- Material certs (ASTM A240 for 304/316L)

- Expanded metal compliance (ASTM F1267)

- Coating reports: ISO 2808, ASTM D3359, ASTM B117/ISO 9227

- ISO 9001, and RoHS/REACH for coatings

- ASTM F1267 – Standard Specification for Expanded Metal

- ASTM A240 – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip

- ASTM D3359 – Standard Test Methods for Rating Adhesion by Tape Test

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus

- ISO 9227 – Corrosion tests in artificial atmospheres — Salt spray tests

- ISO 2808 – Paints and varnishes — Determination of film thickness

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.