Feb . 11, 2025 03:36

Back to list

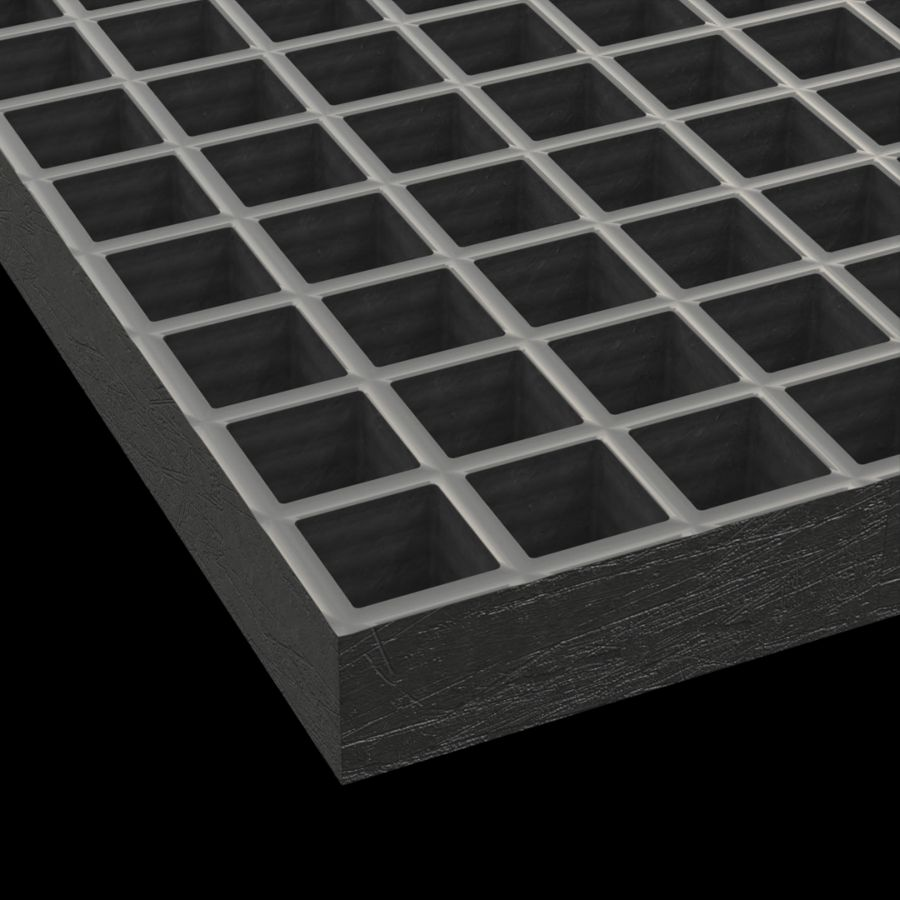

perforated metal sheet

Purchasing perforated sheets requires insight into the factors affecting their price per kilogram. This material, valued for its versatile applications in industries ranging from construction to design, sees its cost influenced by several key aspects. Understanding these factors will not only guide buyers in making informed decisions but also ensure that they leverage the material’s full potential.

Another critical factor to consider is the scale of purchase. Bulk buying typically offers cost benefits due to economies of scale, reducing the price per kilogram. However, such purchases should align with project needs to avoid surplus inventory, which can tie up capital unnecessarily. Establishing a clear understanding of project scope and material requirements aids in optimizing procurement strategies, leading to significant cost savings. Geographical location and transportation logistics are also essential considerations. The proximity to raw material sources and manufacturing facilities can affect shipping costs and timeframes. Regions with abundant access to desired metals may offer more competitive pricing, while distant locations could incur higher transportation costs. Buyers should investigate local availability and potential suppliers in their vicinity to mitigate these expenses. Finally, market conditions significantly impact perforated sheet prices, subject to economic trends, trade policies, and geopolitical events. Fluctuations in metal prices can arise from changes in raw material supplies or shifts in global demand. Staying updated with market trends and fostering relationships with reliable suppliers can provide strategic advantages, allowing buyers to anticipate price movements and plan purchases accordingly. In conclusion, navigating the perforated sheet market necessitates a comprehensive understanding of the myriad factors affecting price per kilogram. Material choice, sheet thickness, perforation patterns, manufacturing processes, purchase scale, location, and market conditions all influence costs. By carefully evaluating these variables, buyers can not only optimize their procurement strategies but also ensure the selected materials meet their project's precise needs, fostering efficiency and performance in application.

Another critical factor to consider is the scale of purchase. Bulk buying typically offers cost benefits due to economies of scale, reducing the price per kilogram. However, such purchases should align with project needs to avoid surplus inventory, which can tie up capital unnecessarily. Establishing a clear understanding of project scope and material requirements aids in optimizing procurement strategies, leading to significant cost savings. Geographical location and transportation logistics are also essential considerations. The proximity to raw material sources and manufacturing facilities can affect shipping costs and timeframes. Regions with abundant access to desired metals may offer more competitive pricing, while distant locations could incur higher transportation costs. Buyers should investigate local availability and potential suppliers in their vicinity to mitigate these expenses. Finally, market conditions significantly impact perforated sheet prices, subject to economic trends, trade policies, and geopolitical events. Fluctuations in metal prices can arise from changes in raw material supplies or shifts in global demand. Staying updated with market trends and fostering relationships with reliable suppliers can provide strategic advantages, allowing buyers to anticipate price movements and plan purchases accordingly. In conclusion, navigating the perforated sheet market necessitates a comprehensive understanding of the myriad factors affecting price per kilogram. Material choice, sheet thickness, perforation patterns, manufacturing processes, purchase scale, location, and market conditions all influence costs. By carefully evaluating these variables, buyers can not only optimize their procurement strategies but also ensure the selected materials meet their project's precise needs, fostering efficiency and performance in application.

Next:

Latest news

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP