Understanding Perforated Plate Steel Applications and Advantages

Perforated plate steel is an incredibly versatile material widely used in various industries, from architecture to manufacturing. As the name suggests, perforated plates are sheets of metal that have been punched with a series of holes to create a patterned surface. This unique design allows for both aesthetic and functional benefits, making perforated plate steel an essential component in modern applications.

One of the primary advantages of perforated plate steel is its ability to reduce weight while maintaining structural integrity

. The holes in the plate create spaces that lighten the overall load without compromising strength. This characteristic is particularly beneficial in construction and automotive industries, where reducing weight can lead to significant cost savings and improved performance.In architectural applications, perforated plates are often used for facades, ceilings, and decorative elements. The patterns created by the holes can enhance visual appeal while also serving practical purposes like sound absorption and natural ventilation. For example, buildings designed with perforated screens can allow light to filter through while still providing shade and privacy, creating a harmonious balance between functionality and design.

perforated plate steel

Moreover, perforated plate steel is commonly utilized in industrial settings for filtration and separation processes. The size and arrangement of the holes can be customized to meet specific needs, making these plates ideal for applications such as mining, food processing, and waste management. The ability to efficiently filter materials while allowing for airflow or liquid passage is crucial in maintaining productivity and safety standards.

Maintenance is another area where perforated plate steel shines. Its durability against environmental factors such as corrosion and wear means that it often requires less upkeep over time compared to other materials. This long lifespan can translate into lower costs and reduced environmental impact, as organizations won’t need to replace parts as frequently.

In conclusion, perforated plate steel offers a multitude of benefits that cater to both aesthetic and practical needs across various industries. Its lightweight nature, strength, versatility in design, and low maintenance requirements make it an invaluable resource. As industries continue to seek innovative solutions, perforated plate steel will remain a vital component in the development of efficient and appealing designs.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

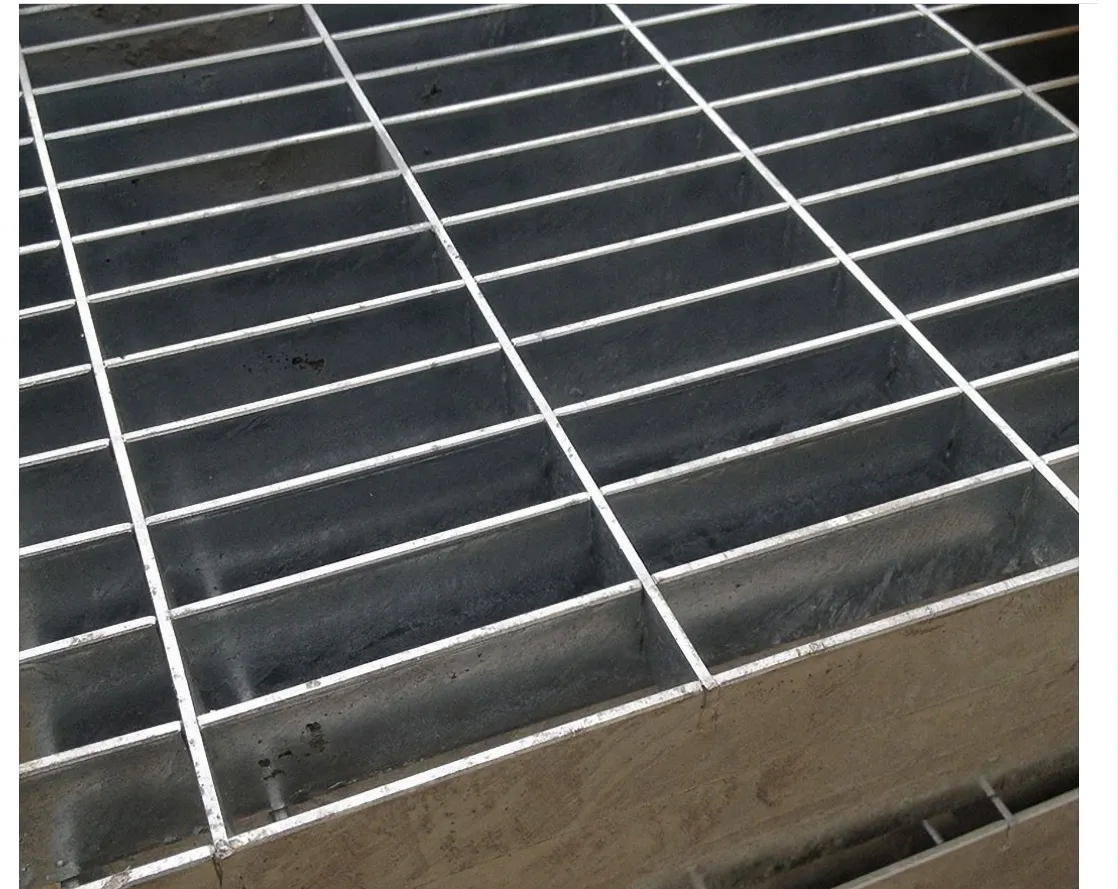

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.