The Versatility of Stainless Perforated Metal

Stainless perforated metal is a remarkable material that has gained significant prominence in various industries due to its unique properties and versatility. Made from stainless steel, this material is characterized by a series of holes or perforations that can be customized in size, shape, and pattern. The combination of durability, aesthetic appeal, and functionality makes stainless perforated metal an ideal choice for numerous applications.

Key Characteristics

The primary advantage of stainless perforated metal is its resistance to corrosion and rust, thanks to the chromium content in stainless steel. This makes it suitable for use in demanding environments, such as marine, chemical, and food processing industries, where exposure to moisture and other corrosive elements is common. Additionally, stainless perforated metal is easy to clean and maintain, ensuring longevity and continued functionality over time.

Another essential feature is its lightweight nature despite its strength. This enables easy handling and installation, reducing labor costs and time during construction or manufacturing processes. Furthermore, the material allows for excellent airflow and visibility, making it a popular choice for architectural applications.

Applications

Stainless perforated metal finds applications in a wide range of sectors. In architecture and design, it is often used as a decorative element in facades, staircases, and railings. The perforations can be designed to create stunning visual effects, allowing natural light to filter through while providing privacy and protection from the elements.

stainless perforated metal

In the industrial sector, stainless perforated metal is widely used for filtration and separation processes. It serves as a screen to filter out unwanted particles in air, liquids, or granular materials, making it invaluable in industries such as mining, pharmaceuticals, and wastewater treatment.

Moreover, the food industry benefits from its use, as stainless perforated metal is employed in equipment like conveyor belts and trays, which must meet stringent hygiene standards

. It allows for easy drainage and airflow, ensuring that food products are handled safely and efficiently.Sustainability and Customization

A growing emphasis on sustainability has led many industries to consider eco-friendly materials. Stainless steel is 100% recyclable, making stainless perforated metal an excellent choice for those looking to reduce their environmental footprint. Choosing this material contributes to sustainable practices while maintaining the strength and durability essential for industrial applications.

The customizable nature of perforated metal further enhances its appeal. Manufacturers can produce sheets with varying hole patterns, thicknesses, and finishes, allowing clients to design products that meet specific requirements. This flexibility ensures that stainless perforated metal can adapt to diverse applications, whether it is a decorative piece in a modern building or a functional component in a manufacturing process.

Conclusion

In conclusion, stainless perforated metal is a multifaceted material with numerous benefits that make it indispensable across various industries. Its durability, aesthetic options, and functional properties demonstrate why it continues to gain traction in both industrial and design sectors. As industries innovate and evolve, the utilization of stainless perforated metal will undoubtedly expand, providing solutions that balance performance, sustainability, and aesthetic appeal. Whether used for practical applications or as a design element, stainless perforated metal stands as a testament to the capabilities of modern manufacturing and engineering.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

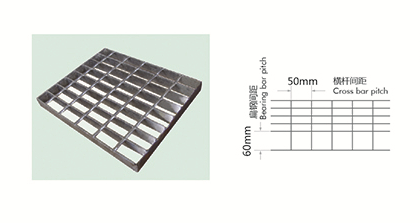

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.