பிப் . 12, 2025 09:45

Back to list

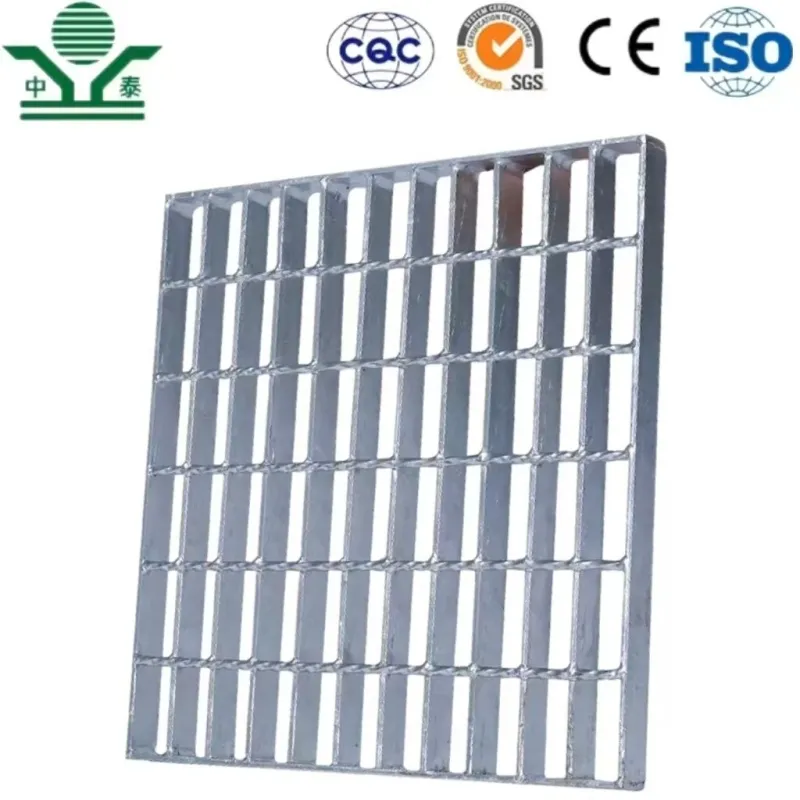

perforated metal plate

The use of perforated stainless steel plates is a cornerstone in many industries, renowned for their durability, versatility, and modern aesthetic appeal. Known for its precise engineering and resilience, a 1/4 perforated stainless steel plate is a product of choice for businesses seeking quality and reliability. With a profound experience in market standards, it is pivotal to delve into the intricacies of why industries are pivoting towards these robust materials and how they impact various sectors from a professional viewpoint.

In the industrial sector, its applications are even more diverse. Trustworthiness in product performance is paramount and perforated stainless steel plates deliver in spades. These materials are employed in processes demanding high heat resilience, such as in chemical plants or food processing facilities. Their ability to withstand harsh environments without degrading extends the lifespan of equipment, contributing significantly to operational efficiency. From an experiential standpoint, users of these plates often commend their ease of maintenance and cost-effectiveness. Unlike other materials that may rust or require frequent replacements, stainless steel boasts a long lifespan, requiring minimal upkeep to maintain its appearance and structural integrity. This property translates to tangible cost savings for businesses, particularly in industries where machinery downtime directly affects productivity and profitability. Moreover, the eco-friendly aspect of stainless steel can't be overlooked. With growing emphasis on sustainability, using recyclable materials like stainless steel supports environmental goals and positions a company as a responsible industry player. Utilizing 1/4 perforated stainless steel plates not only aligns with these green initiatives but also leverages their strength and recyclability for future applications. In conclusion, the 1/4 perforated stainless steel plate stands as a paragon of industrial ingenuity and design acumen. Its inherent properties of durability, aesthetic flexibility, and sustainability underpin its reputation as a worthy investment. As industries evolve, the reliance on materials that offer both functional advantages and environmental responsibility will only increase. Adopting such materials can propel a business leader into new realms of innovation, solidifying its position as an industry authority. With thorough expertise and recognized authority, the benefits of using these plates are not only industry standards but also benchmarks for future growth.

In the industrial sector, its applications are even more diverse. Trustworthiness in product performance is paramount and perforated stainless steel plates deliver in spades. These materials are employed in processes demanding high heat resilience, such as in chemical plants or food processing facilities. Their ability to withstand harsh environments without degrading extends the lifespan of equipment, contributing significantly to operational efficiency. From an experiential standpoint, users of these plates often commend their ease of maintenance and cost-effectiveness. Unlike other materials that may rust or require frequent replacements, stainless steel boasts a long lifespan, requiring minimal upkeep to maintain its appearance and structural integrity. This property translates to tangible cost savings for businesses, particularly in industries where machinery downtime directly affects productivity and profitability. Moreover, the eco-friendly aspect of stainless steel can't be overlooked. With growing emphasis on sustainability, using recyclable materials like stainless steel supports environmental goals and positions a company as a responsible industry player. Utilizing 1/4 perforated stainless steel plates not only aligns with these green initiatives but also leverages their strength and recyclability for future applications. In conclusion, the 1/4 perforated stainless steel plate stands as a paragon of industrial ingenuity and design acumen. Its inherent properties of durability, aesthetic flexibility, and sustainability underpin its reputation as a worthy investment. As industries evolve, the reliance on materials that offer both functional advantages and environmental responsibility will only increase. Adopting such materials can propel a business leader into new realms of innovation, solidifying its position as an industry authority. With thorough expertise and recognized authority, the benefits of using these plates are not only industry standards but also benchmarks for future growth.

Next:

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP