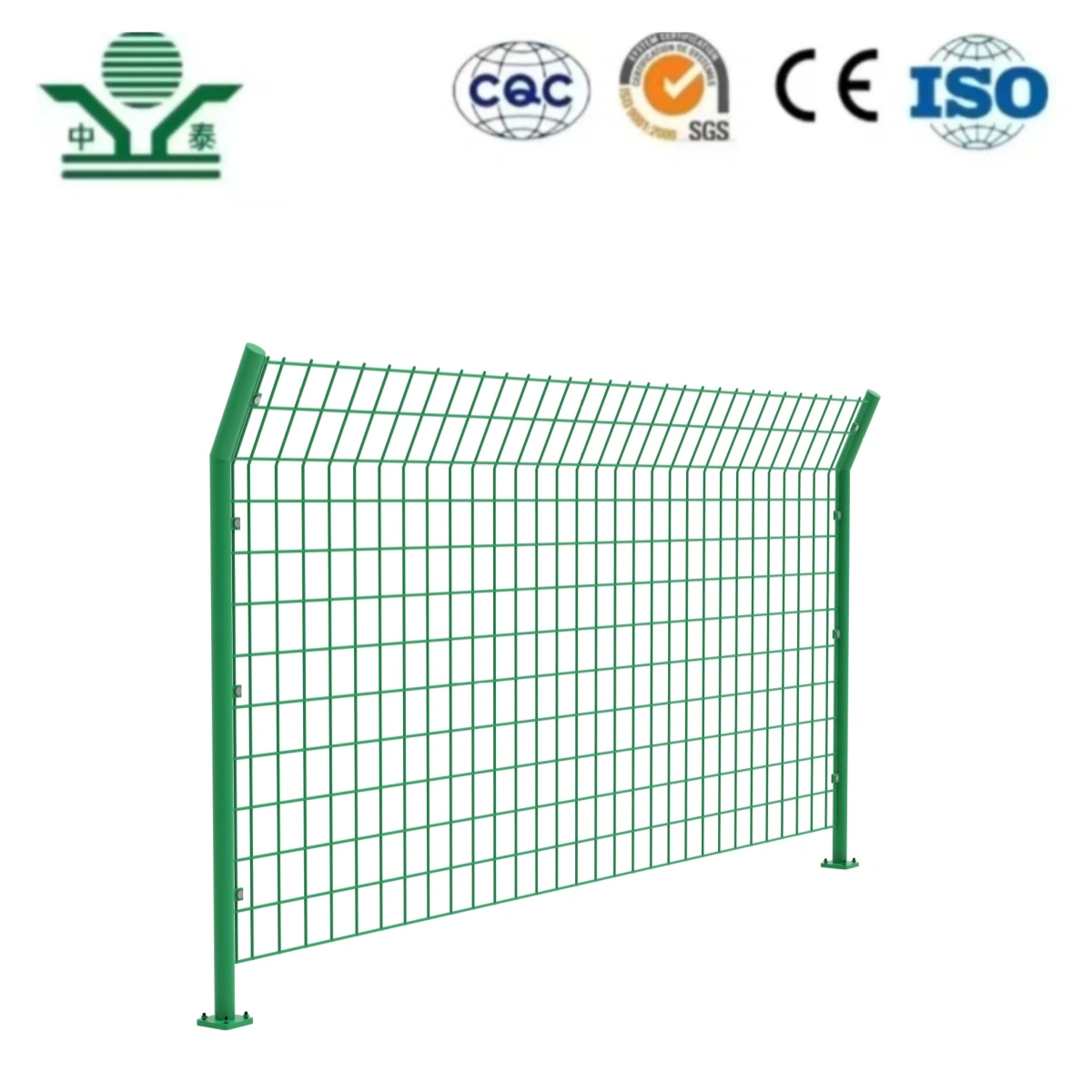

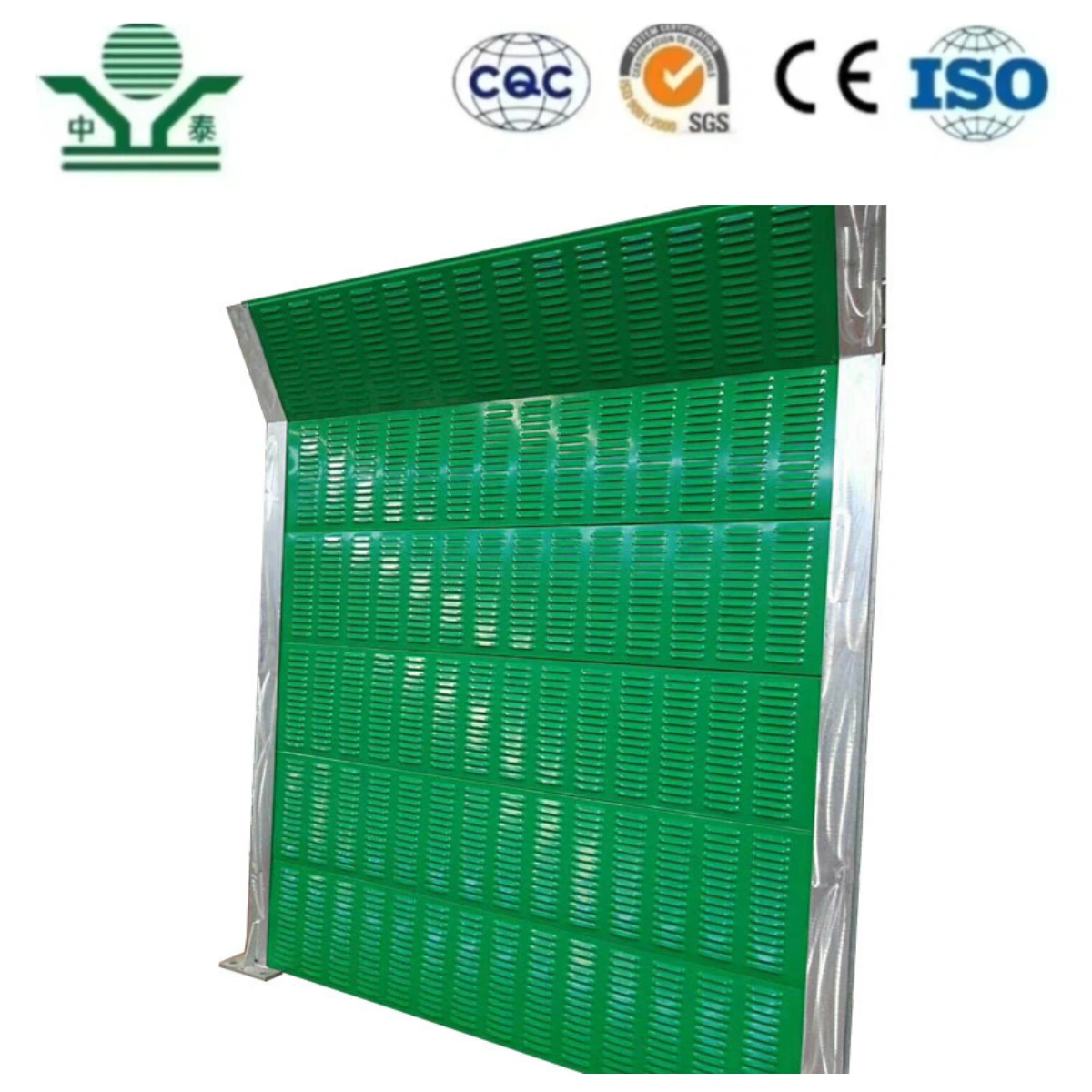

Product Introduction

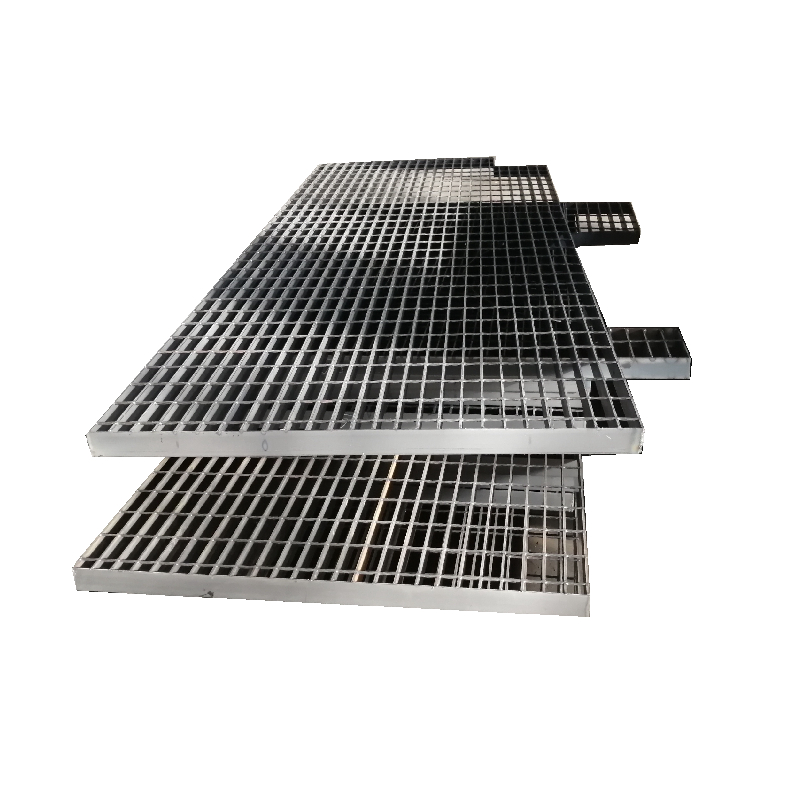

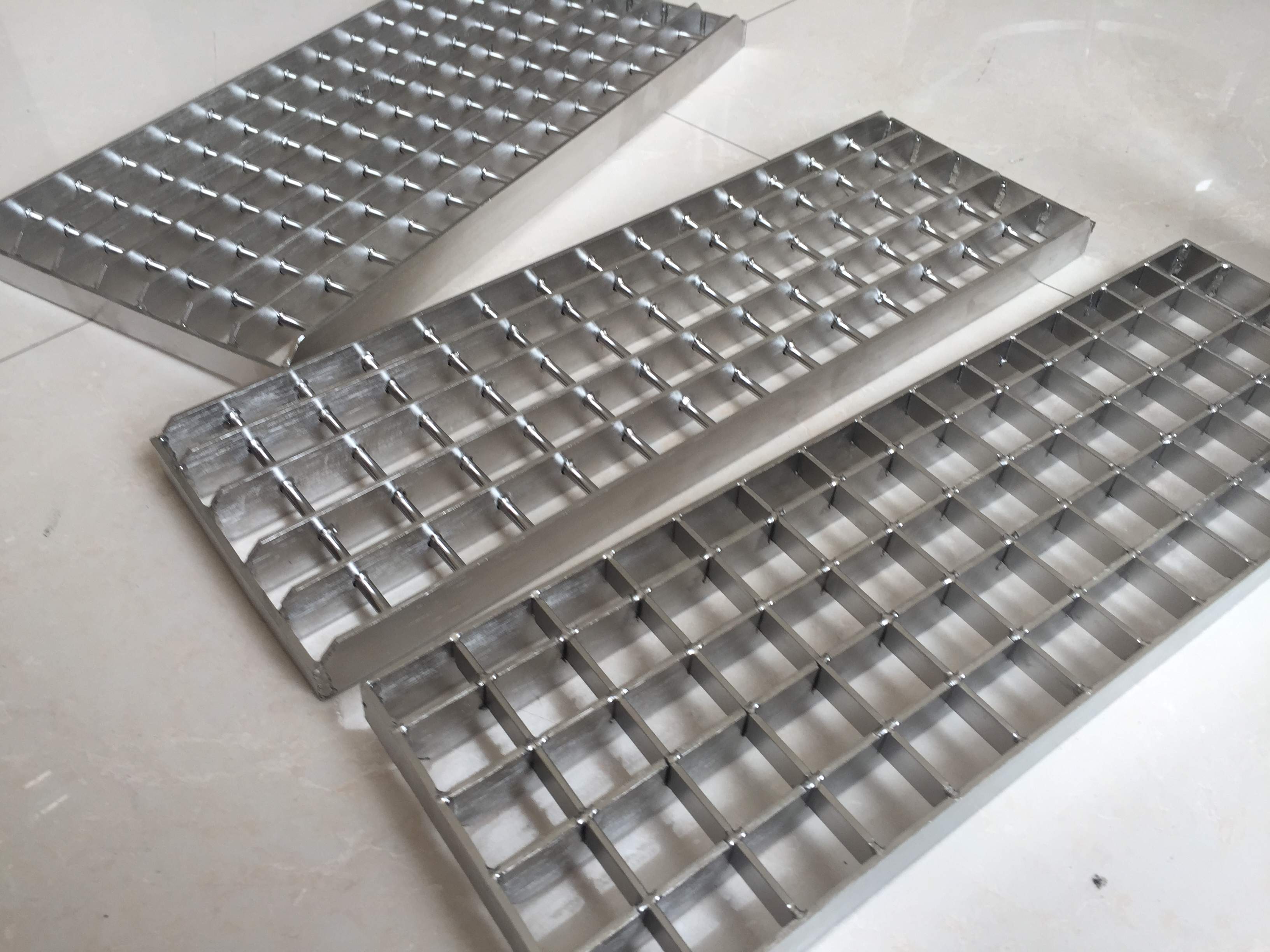

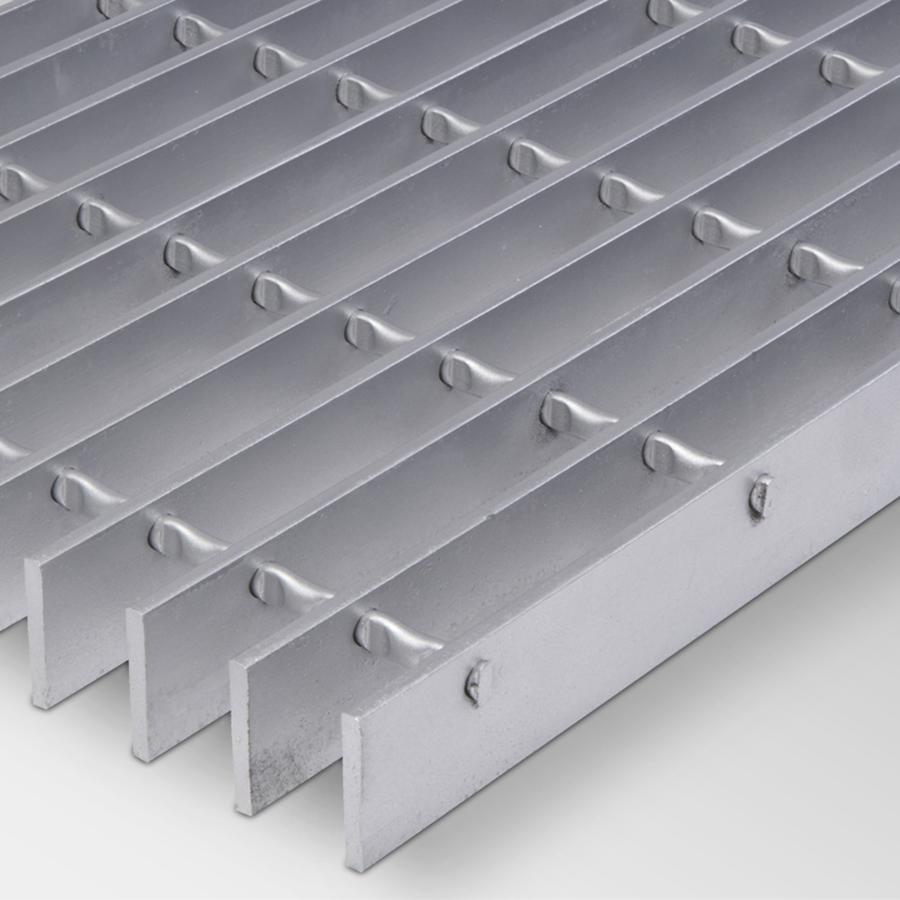

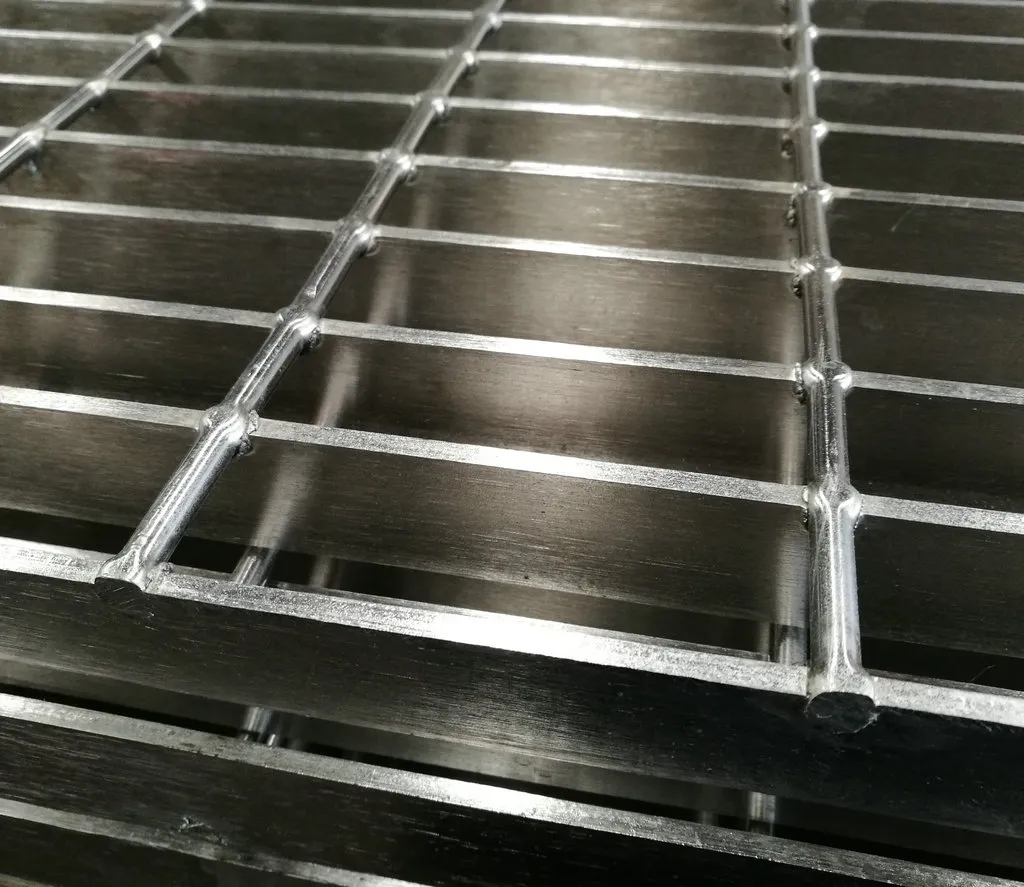

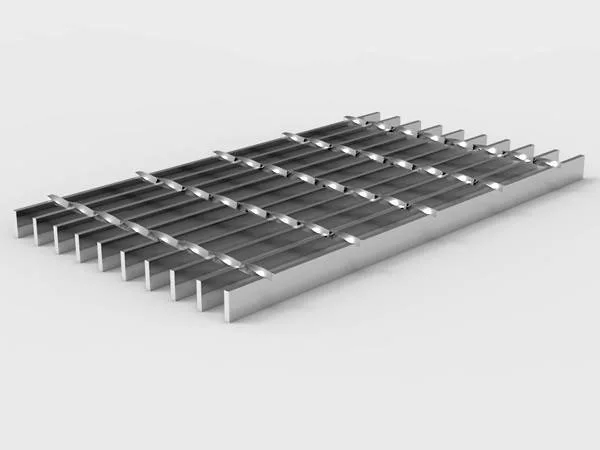

- Both in Smooth or serrated surface.

- 304 or 316 grade for choice.

- Wide range of bearing bar sizes and pitches.

- Special discount for large orders.

- Project references can be supplied for your bid.

- ISO Certificated factory.

- CAD or 3D drawings can be supplied for your design and construction.

THE POPULAR SPECIFICATIONS OF STEEL GRATING

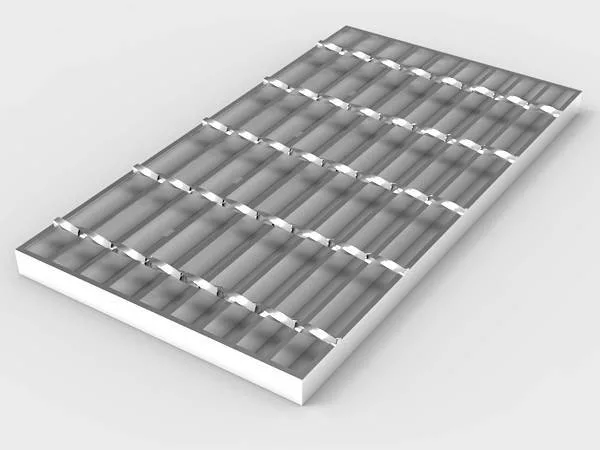

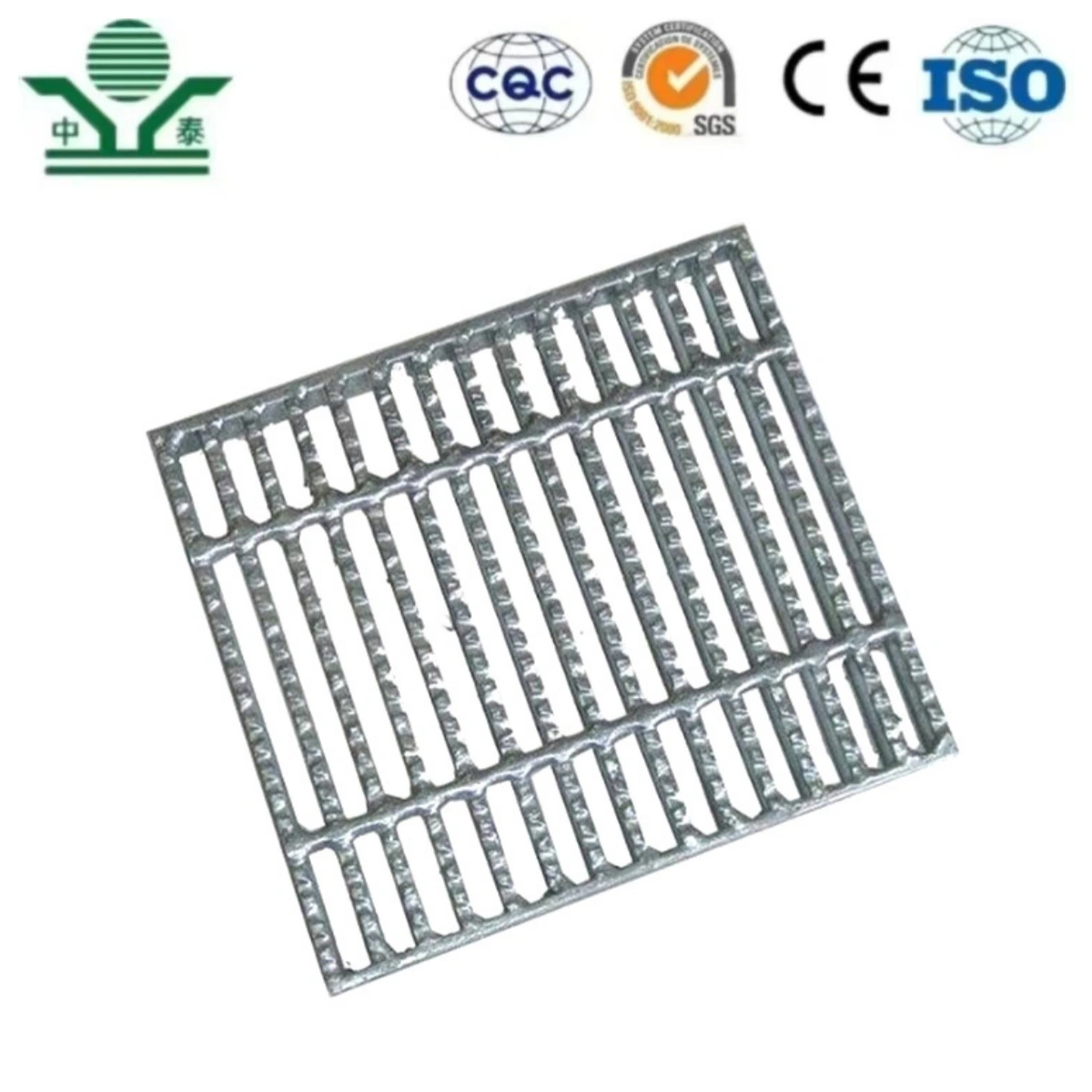

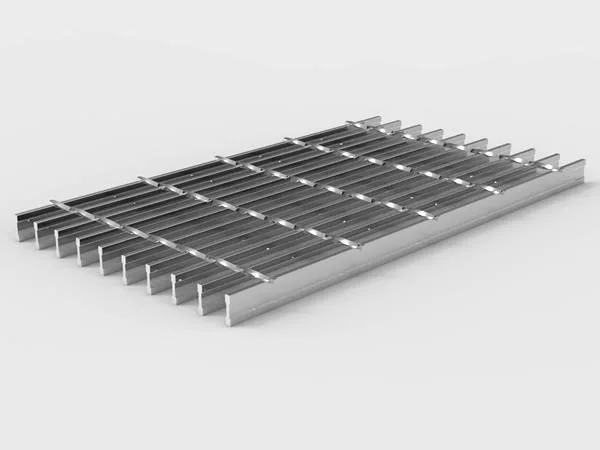

The grating with a pitch of 30mm between bearing bars is the most widely used type in the industrial field. Among normal types, it has the strongest resistance to surface lash.

The grating with a pitch of 40mm between bearing bars is the most economical and lightest type. lt is the best choice for you on occasions when the span is small.

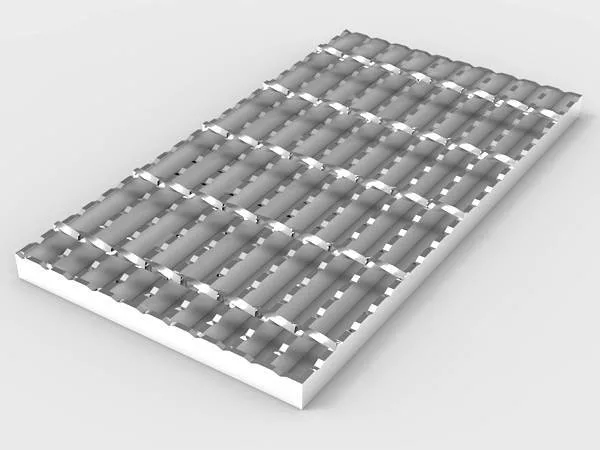

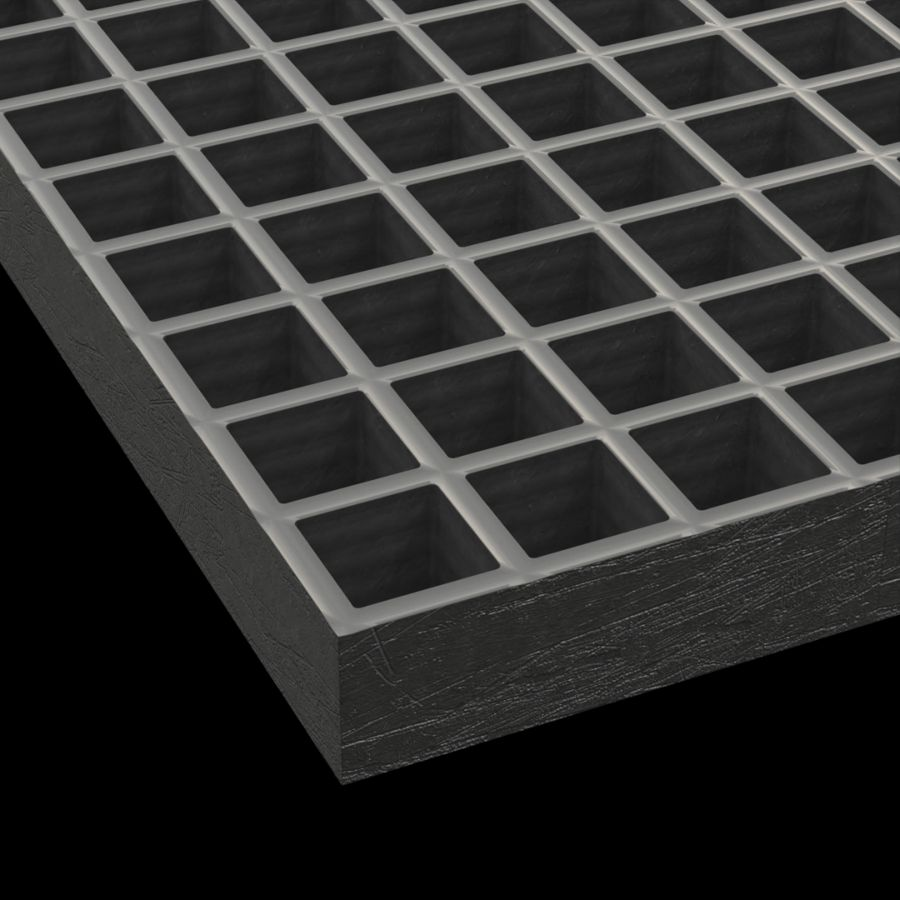

The grating with a pitch of 60mm between the bearing bars and a pitch of 50mm between the cross bars is developed especially for the mining industry, it solved the problem of a mineral splash on the plate. So it is often appointed for use in processing works of the mining industry.

The grating with a pitch of 30mm between bearing bars and of76mm between cross bars is the most popular type used at home and abroad, it is proper for many applications such as walkways, platforms, etc.

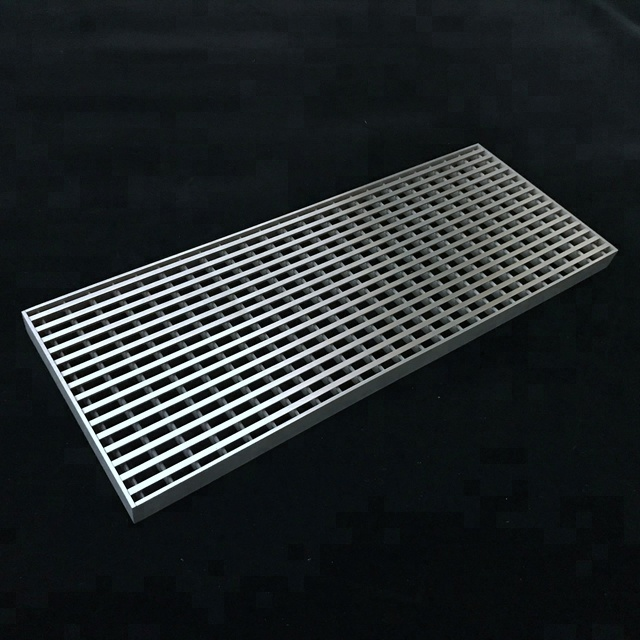

STAINLESS STEEL GRATING - 304 & 316 MATERIALS FOR CORROSIVE PROJECTS

Grating Type

-

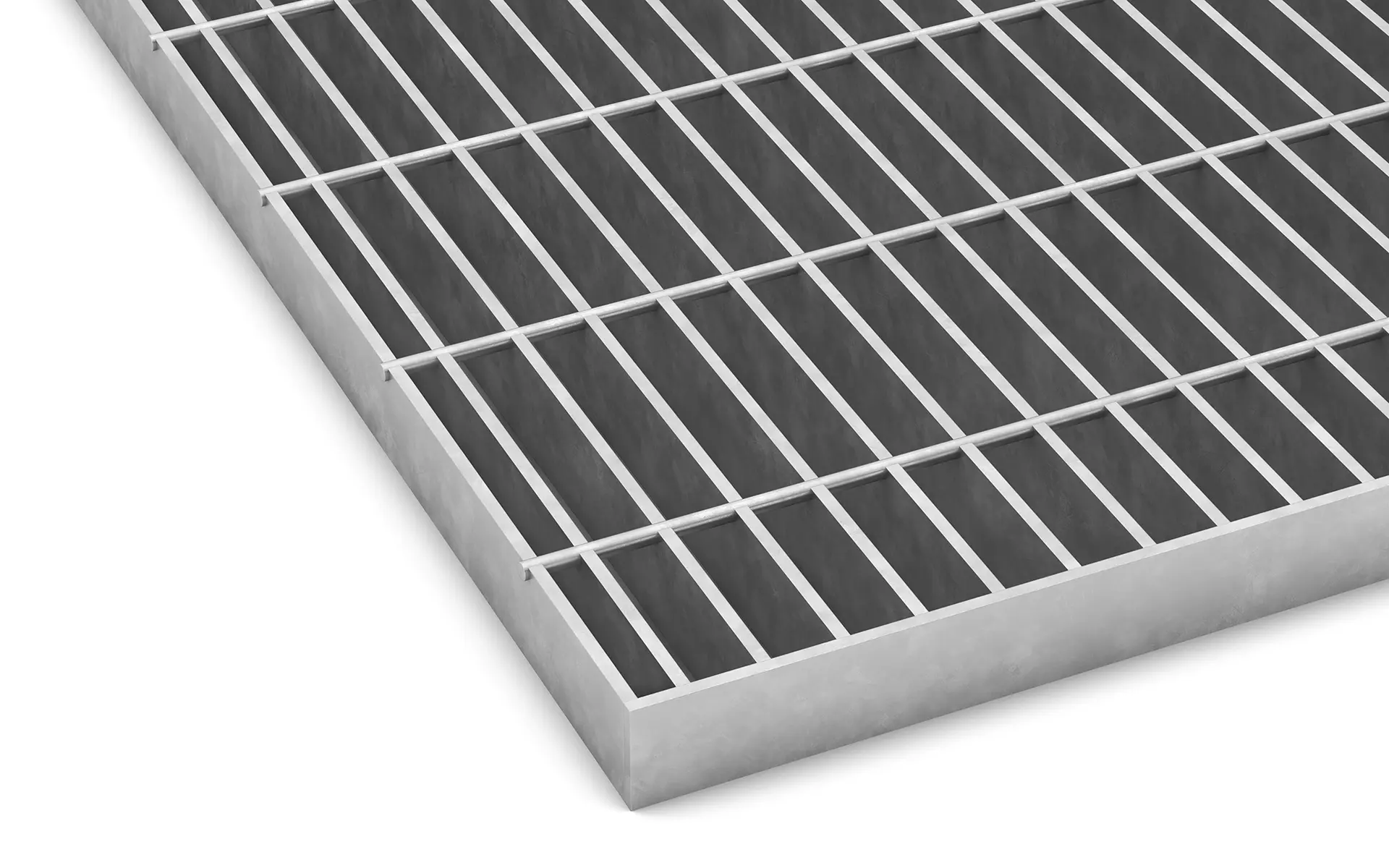

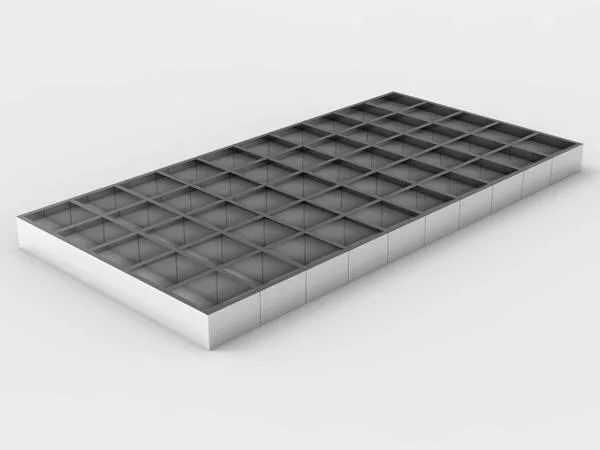

Welded Steel Grating

-

Press lock Steel Grating

Bearing Bar Type

-

Standard/Light Duty Grating

-

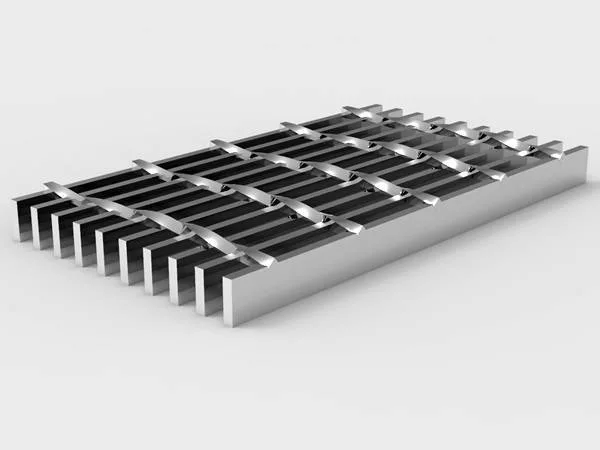

Heavy Duty Grating

-

I Bar Grating

Product Parameters

Dimensions

- Material: stainless steel 304, 304L, 316, 316L.

- Finish: mill finish, commercial clean, and electro-polished.

- Bearing bar spacing: ranging from 1-3/16" to 11/16".

- Cross bar spacing: 2" or 4" on center.

|

Type |

Description |

Tensile Strength |

Yield |

|

304 |

Good corrosion resistance, high tensile strength, excellent for chemical processing, food industries, power plants, and wastewater treatment. Used in high-temperature applications |

75,000 psi (min.) |

30,000 psi (min.) |

|

316 |

Better corrosion and pitting resistance than type 304, and good heat resistance, used in chemical, pulp, and paper processing, marine environments, textile equipment, and petroleum refining. |

75,000 psi (min.) |

30,000 psi (min.) |

- Cross bar spacing: 2" or 4" on center.

|

Metric Legend |

Imperial Legend |

|

U = Safe Uniform Load (kPa) |

U = Safe Uniform Load (lbs./ft2) |

|

Stainless Steel Grade |

Load/Deflection |

Multiply Carbon Steel Load Tables By: |

Based on Maximum Allowable Fiber Stress |

|

304Stainless Steel |

U |

1.111 |

20,000 P.S.I. (137.9 MPa) |

|

C |

1.111 |

|

|

|

D |

1.151 |

|

|

|

304LStainless Steel |

U |

0.917 |

16,500 P.S.I. (113.8 MPa) |

|

C |

0.917 |

|

|

|

D |

0.949 |

|

|

|

316Stainless Steel |

U |

1.111 |

20,000 P.S.I. (137.9 MPa) |

|

C |

1.111 |

|

|

|

D |

1.151 |

|

|

|

316LStainless Steel |

U |

0.917 |

16,500 P.S.I. (113.8 MPa) |

|

C |

0.917 |

|

|

|

D |

0.949 |

|

QUALITY STANDARD

STEEL GRATING STANDARDS:

CHINA: YB/T4001. 1-2007

U.S.A: ANSI / NAAMM(MBG531-88)

U.K: BS4592-1987

STEEL PRODUCT STANDARD:

CHINA : GB700-88

U.S.A: ASTM(A36)

U.K : BS4360(43A)

HOT GALVANIZING STANDARD:

CHINA : GB / T13912

U.S.A: ASTM(A123)

U.K : BS729

SYMBOL OF STEEL GRATING

G 325 /30 /100 F G

G: Sign of steel grating

325: Size of bearing bar ( width x thickness )

30: Bearing bar pitch

100: Cross bar pitch

F: Sign of the shape of bearing bars

G: Sign of surface treatment

NOTE

1, Bearing bar pitches may be 15,22,25,30,32.5,34,40,50,60,80,90mm, of which 25,30,34 and 40mm are recommended.

2, Cross bar pitches maybe 24-200mmof which 50mm,76mm, and 100mm are recommended

3, Sign of the shape of bearing bars: FPlain style(may be committed in the symbol of steel grating)S-Serrated style-I-section style

4. Sign of surface-treatment;G-Hot dipped galvanized(may be omitted in the symbol of steel grating)PPaintedU-Untreated

Detailed Photos