Янв . 20, 2025 12:40

Back to list

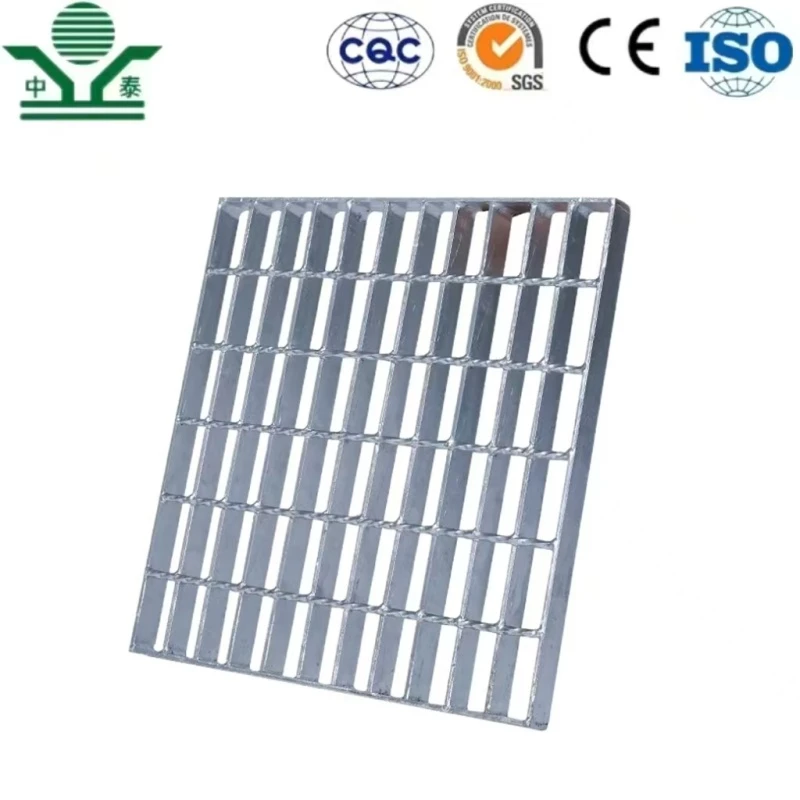

galvanised metal grating

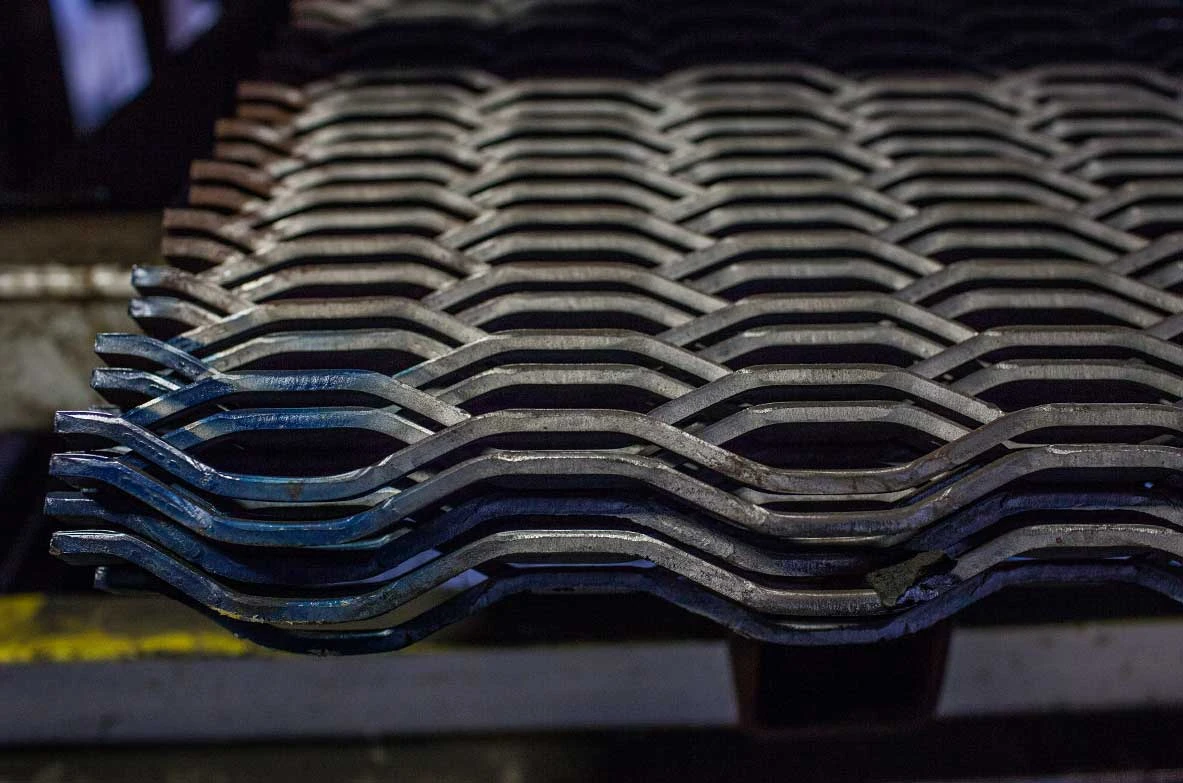

Galvanized metal grating is an indispensable material across many industries due to its robust nature, versatility, and cost-effectiveness. As an expert in construction materials and industrial applications, it's essential to delve into the specific attributes and advantages of this remarkable product to truly understand its role in modern architecture and engineering.

In terms of authoritativeness, recognizing the standards that govern the manufacturing and testing of galvanized metal grating adds a layer of credibility to its application. Adhering to guidelines from institutions such as the American Society for Testing and Materials (ASTM) and the American National Standards Institute (ANSI), these gratings undergo rigorous assessments to ensure they meet specific safety and performance metrics. This compliance not only ensures quality and reliability but also aids in regulatory approvals, providing peace of mind to architects and engineers alike. Trustworthiness in using galvanized metal grating is further established through the endorsements of experienced professionals who consistently rely on it for its proven performance. Testimonials within the industry reflect that infrastructures utilizing galvanized grating often require less maintenance compared to other similar materials. This not only reduces overall project costs but also minimizes downtime—an essential consideration in industrial environments where time equates to monetary loss. Given its demonstrated benefits, the implementation of galvanized metal grating enhances the structural efficacy and safety of various infrastructure projects. Its ability to withstand harsh conditions while maintaining integrity makes it a wise investment for long-term applications. Furthermore, the adaptability of this material allows it to be customized according to the specific needs of each project, whether they involve the creation of raised platforms, safety barriers, or drainage inlets. In conclusion, galvanized metal grating stands out as a versatile, durable, and economical choice in the realm of modern construction materials. Backed by professional expertise, stringent quality standards, and extensive industry trust, it continues to be a preferred option across numerous sectors. Embracing this material not only enhances the physical infrastructures but also fortifies the foundational credibility of any project, delivering on promises of safety, durability, and efficiency.

In terms of authoritativeness, recognizing the standards that govern the manufacturing and testing of galvanized metal grating adds a layer of credibility to its application. Adhering to guidelines from institutions such as the American Society for Testing and Materials (ASTM) and the American National Standards Institute (ANSI), these gratings undergo rigorous assessments to ensure they meet specific safety and performance metrics. This compliance not only ensures quality and reliability but also aids in regulatory approvals, providing peace of mind to architects and engineers alike. Trustworthiness in using galvanized metal grating is further established through the endorsements of experienced professionals who consistently rely on it for its proven performance. Testimonials within the industry reflect that infrastructures utilizing galvanized grating often require less maintenance compared to other similar materials. This not only reduces overall project costs but also minimizes downtime—an essential consideration in industrial environments where time equates to monetary loss. Given its demonstrated benefits, the implementation of galvanized metal grating enhances the structural efficacy and safety of various infrastructure projects. Its ability to withstand harsh conditions while maintaining integrity makes it a wise investment for long-term applications. Furthermore, the adaptability of this material allows it to be customized according to the specific needs of each project, whether they involve the creation of raised platforms, safety barriers, or drainage inlets. In conclusion, galvanized metal grating stands out as a versatile, durable, and economical choice in the realm of modern construction materials. Backed by professional expertise, stringent quality standards, and extensive industry trust, it continues to be a preferred option across numerous sectors. Embracing this material not only enhances the physical infrastructures but also fortifies the foundational credibility of any project, delivering on promises of safety, durability, and efficiency.

Latest news

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP