Янв . 15, 2025 01:06

Back to list

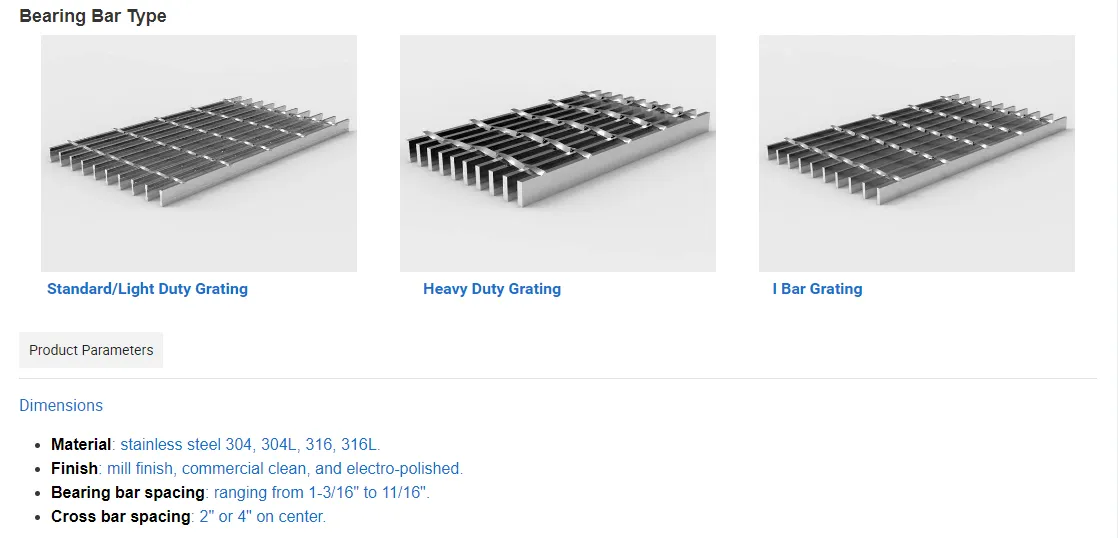

floor grating steel

Floor grating steel, a critical component in industrial flooring systems, offers a robust solution to diverse infrastructure needs across sectors. Its growing popularity is not just a result of its utility, but also due to extensive research, innovative design improvements, and its ability to withstand extreme conditions. The right selection of floor grating steel can significantly enhance safety, efficiency, and longevity in industrial environments.

Authoritativeness in this field comes from decades of industry experience and relentless innovation. Manufacturers and suppliers of steel grating must adhere to stringent international standards, such as ANSI/NAAMM (MBG 531) or Eurocodes, ensuring quality and consistency in their products. Additionally, compliance with safety certifications and industry regulations, including occupational safety and health measures, fortifies the reliability and credibility of the products they offer. Trustworthiness is cultivated through proven performance in the field. Real-world case studies demonstrate floor grating steel's impact across various sectors, from improving productivity in manufacturing plants to ensuring the safety of personnel in offshore installations. Users often look for products that have been verified by independent testing and have received certifications from reputable organizations, instilling confidence in their procurement decisions. In conclusion, floor grating steel remains a cornerstone in industrial applications due to its unmatched strength, versatility, and safety features. When assessing your next project or upgrade, consider engaging with experts who can provide comprehensive insights and solutions tailored to your needs. By focusing on genuine experience, demonstrated expertise, authoritative standards, and building trustworthy relationships, you can ensure that your floor grating steel solution not only meets but exceeds expectations.

Authoritativeness in this field comes from decades of industry experience and relentless innovation. Manufacturers and suppliers of steel grating must adhere to stringent international standards, such as ANSI/NAAMM (MBG 531) or Eurocodes, ensuring quality and consistency in their products. Additionally, compliance with safety certifications and industry regulations, including occupational safety and health measures, fortifies the reliability and credibility of the products they offer. Trustworthiness is cultivated through proven performance in the field. Real-world case studies demonstrate floor grating steel's impact across various sectors, from improving productivity in manufacturing plants to ensuring the safety of personnel in offshore installations. Users often look for products that have been verified by independent testing and have received certifications from reputable organizations, instilling confidence in their procurement decisions. In conclusion, floor grating steel remains a cornerstone in industrial applications due to its unmatched strength, versatility, and safety features. When assessing your next project or upgrade, consider engaging with experts who can provide comprehensive insights and solutions tailored to your needs. By focusing on genuine experience, demonstrated expertise, authoritative standards, and building trustworthy relationships, you can ensure that your floor grating steel solution not only meets but exceeds expectations.

Next:

Latest news

-

Trusted Expanded Metal Mesh For All Projects

NewsMay.08,2025

-

Stainless Steel Expanded Metal for Versatile Uses

NewsMay.08,2025

-

Reliable Steel Grating Choices

NewsMay.08,2025

-

Perforated Sheet Metal for Every Need

NewsMay.08,2025

-

Heavy Duty Expanded Metal Mesh for Robust Solutions

NewsMay.08,2025

-

Expanded Aluminum Metal for Versatile Applications

NewsMay.08,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP