Understanding Dutch Weave A Unique Weaving Technique

Dutch weave, a specialized type of weaving technique, is renowned for its versatile applications and distinctive characteristics. Originating in the Netherlands, this method combines traditional weaving practices with modern industrial techniques, resulting in a product that offers strength, durability, and significant utility in various fields, particularly in filtration and mesh applications. This article delves into the intricacies of Dutch weave, its types, applications, and its advantages over other weaving methods.

What is Dutch Weave?

Dutch weave is a pattern characterized by its meticulous arrangement of warp and weft threads. The fundamental aspect of this technique lies in its construction, where the warp threads are typically made of thicker wires, whereas the weft threads are finer, leading to a firm yet flexible fabric. The resulting mesh exhibits a distinctive surface with high strength and an open area, making it suitable for applications requiring durability without compromising on airflow or liquid passage.

This weaving method is categorized mainly into three types Dutch plain weave, Dutch twill weave, and Dutch waffle weave. Each type offers varying degrees of tightness and breathability, catering to different industrial needs. For instance, Dutch plain weave has a more uniform structure, making it ideal for applications demanding consistency, while Dutch twill weave introduces a diagonal pattern that enhances flexibility and strength, preferable in applications that involve mechanical stress.

Applications of Dutch Weave

One of the most significant applications of Dutch weave is in the filtration industry. Due to its strong structure and fine openings, Dutch weave is perfect for separating fluids from solids, making it a sought-after material in water treatment plants, food processing facilities, and chemical processing industries. The mesh’s ability to withstand high pressure without deforming ensures efficient filtration processes, contributing to increased safety and productivity.

Moreover, Dutch weave is utilized in the manufacturing of sieves and screens, where precise measurement of particle sizes is essential. The customizable nature of the weaving allows manufacturers to create tailor-made solutions that meet specific industry standards, optimizing performance. Additionally, the high tensile strength of Dutch weave makes it a preferred choice in constructing conveyor belts and other mechanical components that require reliable structural integrity.

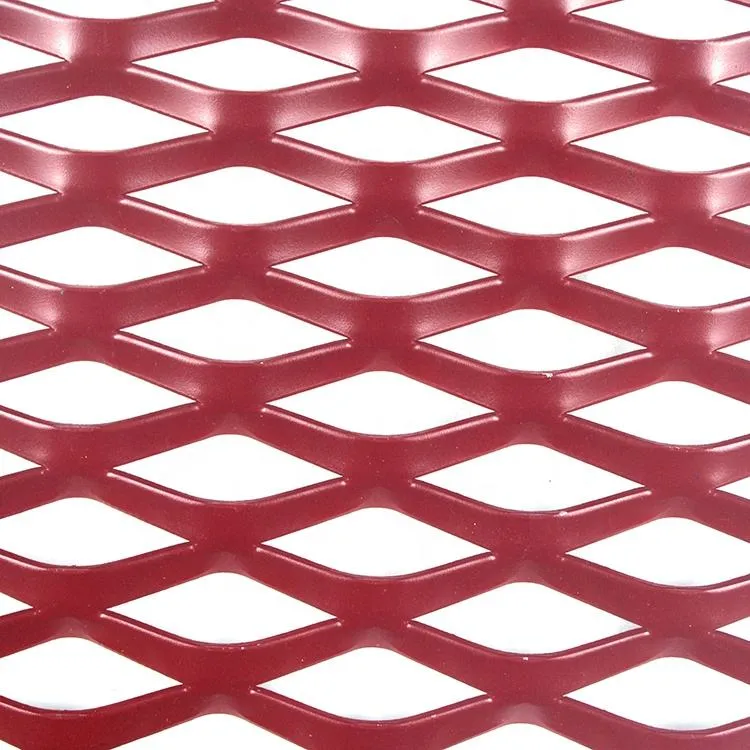

dutch weave

In the aerospace and automotive industries, the light weight and high strength of Dutch weave materials are harnessed for producing filters and screens that operate under extreme conditions. Engineers rely on the consistent quality and durability of Dutch weave to enhance the performance and safety of components, demonstrating the versatility of this weaving technique.

Advantages of Dutch Weave

The advantages of Dutch weave extend beyond its structural properties. One of the primary benefits is its resistance to corrosion and wear, particularly when woven from stainless steel or other alloys. This characteristic is crucial for applications exposed to harsh chemicals or extreme temperatures, ensuring longevity and lower replacement costs.

Additionally, the uniformity in the aperture sizes facilitates controlled filtration and sieving, allowing industries to achieve precise separations. This advantage minimizes product loss and enhances efficiency, making it a favorite in sectors focused on quality control and product optimization.

Another significant benefit of Dutch weave is its ease of maintenance. Its strong, sturdy weave can withstand gentle cleaning processes without losing integrity, making it ideal for industries where hygiene is paramount, such as food and pharmaceuticals.

Conclusion

In conclusion, Dutch weave is not merely a weaving technique; it represents a blend of artistry and engineering. Its unique characteristics and versatile applications position it as an essential material in various industries, from filtration to mechanical components. As industries continue to evolve and demand higher performance from materials, Dutch weave stands out as a reliable solution, balancing durability, functionality, and efficiency. Whether in the field of industrial filtration or the production of intricate screens, Dutch weave showcases the beauty of traditional craftsmanship fused with modern technological advancements, solidifying its place in the fabric of contemporary manufacturing.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.