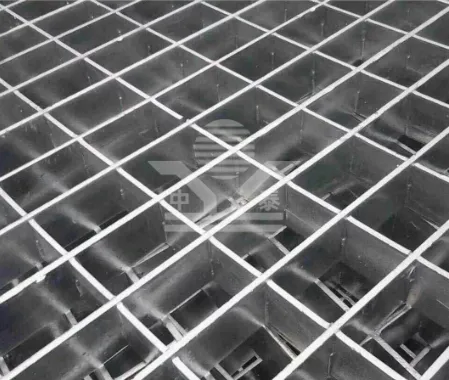

Serrated Steel Grating Combining Safety and Durability in Industrial Applications

Serrated steel grating is an essential component in various industrial applications, known for its outstanding properties in terms of safety, durability, and functionality. It consists of parallel steel bars spaced apart with serrated edges, which provide enhanced slip resistance and support in demanding environments. In this article, we will explore the benefits, applications, and maintenance of serrated steel grating.

What is Serrated Steel Grating?

Serrated steel grating is made up of steel pieces that are cut and positioned in such a way that creates a series of ridges and valleys. The “serrated” aspect refers to the saw-like edges of the bars, which are designed to increase grip and reduce the risk of slips and falls. This makes it particularly valuable in environments where moisture, oils, or other slippery substances may be present. The design not only adds to the aesthetic appeal of the grating but also ensures the safety of personnel who are required to walk, stand, or work on these surfaces.

Benefits of Serrated Steel Grating

1. Enhanced Safety The primary advantage of serrated steel grating is its superior slip resistance. The serrations create additional friction, allowing individuals to maintain their footing even in the presence of wet or oily conditions. This makes it an ideal choice for walkways, platforms, and staircases in areas prone to spills.

2. Durability Made from high-quality steel, serrated grating is built to withstand heavy loads and resist harsh environmental conditions. It is commonly used in industrial settings where structural integrity is crucial. The steel’s inherent strength ensures longevity, making it a cost-effective choice for businesses.

3. Versatility Serrated steel grating is not limited to industrial applications. It is also utilized in commercial spaces, outdoor settings, and even residential projects. From HVAC systems to drainage grates, the applications are numerous and varied.

4. Ease of Installation Serrated steel grating is relatively easy to install and can be cut to size to fit specific requirements. This adaptability streamlines construction processes and allows for quick repairs or upgrades.

5. Low Maintenance Once installed, serrated steel grating requires minimal maintenance. Regular inspections and cleaning are sufficient to ensure its functionality and safety, further adding to its appeal for busy work environments.

Applications of Serrated Steel Grating

serrated steel grating

Serrated steel grating finds its application across numerous industries, including

- Oil and Gas In oil rigs and refineries, where spills and leaks are common, serrated grating provides a safe working platform for personnel.

- Chemical Plants The chemical industry often deals with hazardous substances that can create slippery conditions. Serrated steel grating helps mitigate risks associated with chemical spills.

- Food Processing In food processing facilities, cleanliness and safety are paramount. Serrated grating can be easily cleaned and maintains a safe surface for workers.

- Construction Construction sites often require temporary walkways and platforms. Serrated steel grating is favored for its strength and slip-resistant properties.

- Transportation Railways and airports use serrated grating in areas where passengers and workers need secure footing, especially during inclement weather.

Maintenance of Serrated Steel Grating

Despite its durability, regular maintenance is crucial to ensure the longevity of serrated steel grating. A routine cleaning schedule should be established to remove debris, oil, and other substances that may accumulate over time. Inspecting for signs of wear, rust, or deformation is also vital. In environments with heavy usage, applying anti-corrosive paints or coatings can further extend the life of the grating.

Conclusion

Serrated steel grating is a quintessential component in ensuring safety and efficiency in various industrial applications. Its slip-resistant design, combined with its durability and versatility, makes it an invaluable resource across numerous sectors. As industries continue to prioritize worker safety and operational efficiency, serrated steel grating will undoubtedly maintain its significance in the industrial landscape. Whether for new construction or retrofitting existing structures, this type of grating provides the perfect blend of functionality and security necessary for today’s demanding environments.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.