The Use of Wire Gauze in Laboratory and Industrial Settings

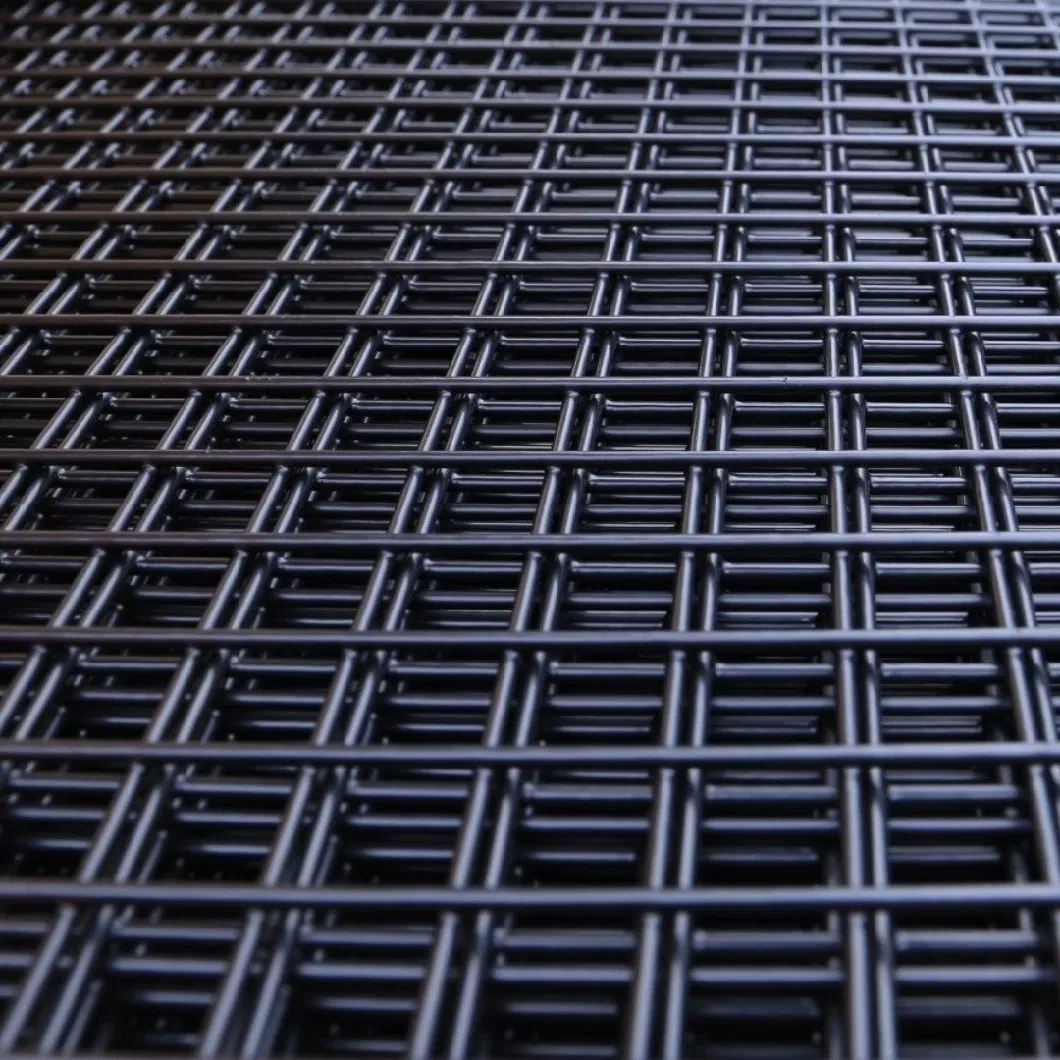

Wire gauze is an essential tool in laboratory and industrial environments, widely recognized for its ability to provide support and safety during heating processes. Made from woven metal strands, wire gauze is commonly used in conjunction with a Bunsen burner or other heat sources. Its role is multifaceted, making it a staple in various scientific and manufacturing procedures.

The Use of Wire Gauze in Laboratory and Industrial Settings

In addition to promoting even heat distribution, wire gauze serves as a protective barrier. For instance, when a reaction produces gases or liquids that may spill, the gauze can prevent direct exposure to the flame, reducing the likelihood of fire hazards. Furthermore, the wire mesh acts as a physical barrier that can catch glass shards or other materials if an accident occurs, providing an additional layer of safety in the workspace.

what is the use of wire gauze

Wire gauze is also used in industrial contexts, particularly in the manufacture of materials that require controlled heating. It is often placed on top of a support stand to hold containers above a heat source. This application is critical in processes such as metallurgy and chemical production, where specific temperatures must be maintained over extended periods.

Moreover, wire gauze can be utilized in filtration systems. In certain situations, it can act as a sieve to separate larger particles from liquids or gases, ensuring only the desired materials pass through. This characteristic makes it versatile across different industries, from food processing to pharmaceuticals.

In summary, wire gauze is a vital component in both laboratory and industrial settings, facilitating safer and more efficient heating processes. Its ability to distribute heat evenly and provide a protective barrier makes it indispensable in various applications, underscoring its importance in conducting safe scientific and manufacturing practices.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.