Understanding Metric Perforated Sheet Metal An Overview

Perforated sheet metal is an essential material used across various industries due to its unique properties and versatility. This article will explore the characteristics, applications, benefits, and considerations associated with metric perforated sheet metal.

What is Perforated Sheet Metal?

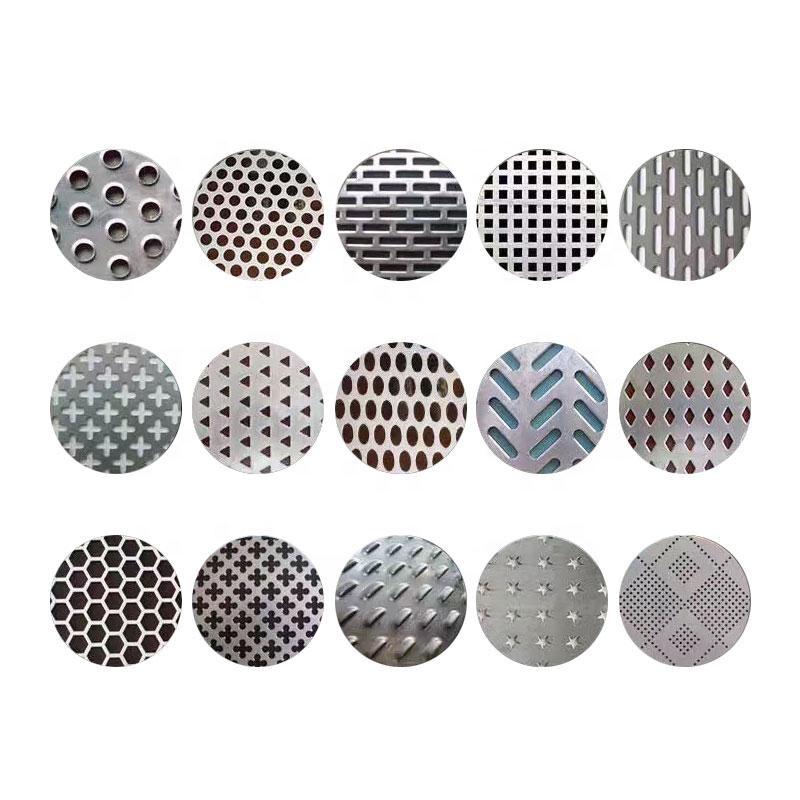

Perforated sheet metal is a flat piece of metal that has been punched or stamped with a pattern of holes. These holes can vary in size, shape, and spacing, allowing for a wide range of design possibilities. Metric perforated sheet metal specifically refers to sheets manufactured and measured using the metric system, making it compatible with Global Standards that many industries adhere to. This is particularly useful for companies operating internationally, as it streamlines manufacturing processes and ensures accurate measurement across regions.

Characteristics of Metric Perforated Sheet Metal

1. Material Variety Perforated sheet metal can be made from various materials, including stainless steel, aluminum, brass, and mild steel. Each material has its unique properties, such as corrosion resistance, weight, and strength.

2. Customizable Hole Patterns The design flexibility is a significant advantage of perforated sheet metal. Manufacturers can create custom hole patterns tailored to specific needs, whether for aesthetic purposes, sound attenuation, or functional applications such as airflow and light transmission.

3. Strength and Durability Despite being perforated, these sheets maintain significant strength and durability, making them suitable for industrial and architectural applications.

4. Lightweight Generally, perforated sheets are lighter than solid sheets of the same dimensions, making them easier to handle, transport, and install.

5. Thermal Resistance Many types of perforated metal sheets offer good heat resistance, making them suitable for environments where temperature fluctuations are common.

Applications of Metric Perforated Sheet Metal

The applications of metric perforated sheet metal are diverse

1. Architectural Design In architecture, perforated sheets are used for facades, partitions, and sunshades. They not only provide visual interest but also allow natural ventilation and light, enhancing the overall aesthetics of buildings.

metric perforated sheet metal

2. Industrial Uses In manufacturing and industrial settings, perforated sheets are used as filters, conveyors, or protective barriers. They can facilitate air and water flow while protecting internal mechanisms from debris or contamination.

3. Automotive Industry Perforated metal is often used in automotive applications, including grills, heat shields, and interior panels. Its lightweight and strong characteristics contribute to lighter vehicle designs without compromising safety.

4. Audio Applications Due to their ability to disperse sound, perforated metal sheets are often used in acoustic panels, speaker grills, and soundproofing applications.

5. Furniture Design The use of perforated metal in furniture design has gained popularity, providing a modern and trendy aesthetic while maintaining functionality. Chairs, tables, and shelving units featuring perforated designs are becoming increasingly common.

Benefits of Using Metric Perforated Sheet Metal

Using metric perforated sheet metal offers several advantages

- Customization With various hole sizes and configurations available, it can be customized to meet specific project needs. - Cost-Effectiveness Perforated sheets often use less material than solid sheets, while still providing the needed strength. - Aesthetic Appeal The ability to create unique designs can significantly enhance the visual appeal of a product or structure. - Efficiency The permeability of perforated metal allows for better airflow and light penetration, which can improve energy efficiency in buildings and machinery.

Considerations

When selecting metric perforated sheet metal for a project, consider the following

- Material Properties Choose a material that fits the specific environmental and physical demands of the application. - Hole Size and Pattern Ensure that the hole size and pattern align with the intended use while also meeting aesthetic requirements. - Thickness The thickness of the sheet will impact its strength, durability, and overall appearance.

Conclusion

Metric perforated sheet metal is a versatile and valuable material used in numerous applications across various industries. Its unique characteristics, combined with the benefits it offers, make it an ideal choice for both functional and ornamental uses. By understanding the properties, applications, and considerations associated with this material, designers and engineers can make more informed choices in their projects. Whether for architectural innovations, industrial solutions, or furniture design, metric perforated sheet metal continues to demonstrate its relevance in modern manufacturing and design.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.