ਜਨਃ . 14, 2025 12:25

Back to list

grating types

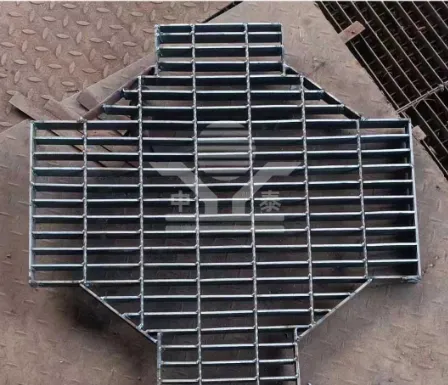

Gratings are invaluable components across various industries, offering functional and safety solutions tailored to specific needs. Grating types vary significantly, each designed to meet particular specifications, environmental conditions, and regulatory standards, making their understanding critical for selecting the right product for your application.

Size and configuration options further tailor gratings to meet operational demands. Bar spacing, thickness, and depth should align with specific load and deflection requirements, ensuring optimal performance and safety. Customization capabilities allow for the integration of additional features like slip resistance, crucial for applications in areas prone to moisture or spillages. Ensuring safety and reliability, anti-slip gratings provide enhanced traction, fundamental in wet or oily conditions. These gratings feature serrated surfaces that mitigate slipping hazards, thus fostering a secure environment in potentially hazardous zones like industrial kitchens or oil rigs. The integration of cutting-edge technology continues to revolutionize grating solutions. Smart gratings equipped with sensors to monitor structural integrity and load offer preventive maintenance advantages, minimizing downtime and enhancing operational efficiency. These innovations align with modern industry trends where data-driven maintenance increases productivity and safety. In conclusion, the diversity of grating types aligns with a wide array of industrial requirements, emphasizing the necessity of understanding different materials, manufacturing processes, and additional safety features. A detailed analysis and expert guidance ensure the selection of a grating solution that not only meets the operational requirements but also ensures long-term reliability and safety. Industry professionals are encouraged to consult with grating specialists to determine the most suitable grating type for their specific application, upholding the integrity and efficiency of their operations.

Size and configuration options further tailor gratings to meet operational demands. Bar spacing, thickness, and depth should align with specific load and deflection requirements, ensuring optimal performance and safety. Customization capabilities allow for the integration of additional features like slip resistance, crucial for applications in areas prone to moisture or spillages. Ensuring safety and reliability, anti-slip gratings provide enhanced traction, fundamental in wet or oily conditions. These gratings feature serrated surfaces that mitigate slipping hazards, thus fostering a secure environment in potentially hazardous zones like industrial kitchens or oil rigs. The integration of cutting-edge technology continues to revolutionize grating solutions. Smart gratings equipped with sensors to monitor structural integrity and load offer preventive maintenance advantages, minimizing downtime and enhancing operational efficiency. These innovations align with modern industry trends where data-driven maintenance increases productivity and safety. In conclusion, the diversity of grating types aligns with a wide array of industrial requirements, emphasizing the necessity of understanding different materials, manufacturing processes, and additional safety features. A detailed analysis and expert guidance ensure the selection of a grating solution that not only meets the operational requirements but also ensures long-term reliability and safety. Industry professionals are encouraged to consult with grating specialists to determine the most suitable grating type for their specific application, upholding the integrity and efficiency of their operations.

Latest news

-

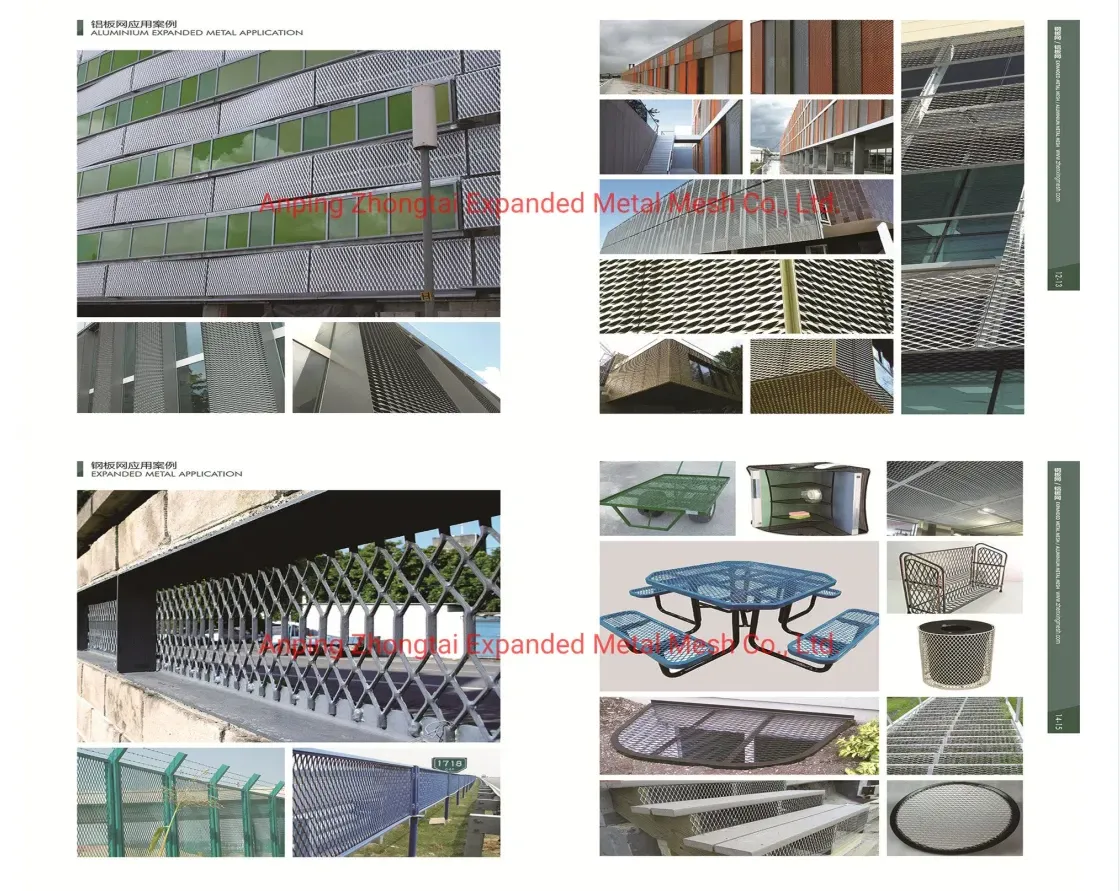

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP