Different Types of Wire Mesh Understanding Their Applications and Benefits

Wire mesh is a versatile material used in a wide range of industrial, commercial, and residential applications. It is formed by weaving or welding strands of metal wire together to create a grid-like structure. The various types of wire mesh available cater to diverse needs, depending on the material, size, and intended use. This article explores the different types of wire mesh and highlights their unique characteristics and benefits.

1. Welded Wire Mesh

Welded wire mesh is created by welding together metal wires at their intersections. This type of mesh provides excellent strength and stability, making it ideal for construction and reinforcement purposes. Commonly used in concrete slabs, walls, and fences, welded wire mesh comes in various gauges and sizes, allowing for customized applications. Its durability is particularly advantageous in environments exposed to harsh weather and heavy loads.

2. Wire Cloth

Wire cloth is a type of woven wire mesh characterized by its finer openings. It is often made from stainless steel, copper, or other materials, providing varying levels of corrosion resistance. Wire cloth is widely used in filtration applications, such as water treatment and food processing, where precise size openings are crucial for separating materials. Additionally, it serves as an effective barrier in industrial processes, protecting equipment from debris and contamination.

Expanded metal mesh is created by slitting and stretching a metal sheet to form diamond-shaped openings. This type of wire mesh is lightweight yet strong, making it suitable for applications such as walkways, stair treads, and security fencing. Its design allows for excellent airflow and visibility while providing a secure barrier. Expanded metal mesh is popular in architectural applications due to its aesthetic appeal and functional properties.

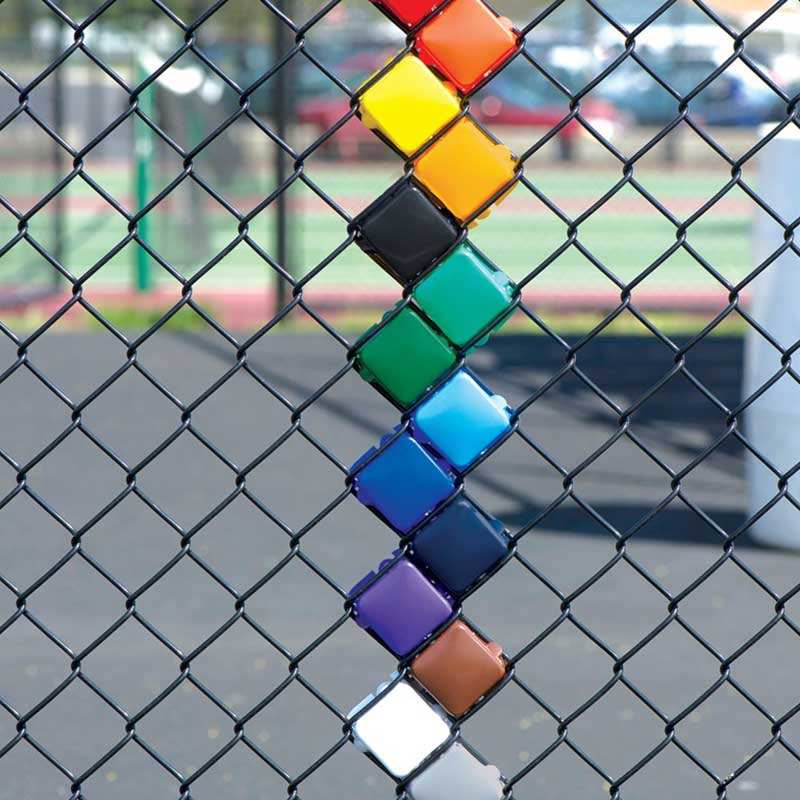

4. Chain Link Fence

different types of wire mesh

Chain link mesh is a type of woven wire mesh, typically used for fencing. It is made from galvanized steel or vinyl-coated wire, providing a durable and cost-effective solution for enclosing properties. Chain link fences are commonly found in residential, commercial, and industrial settings, offering security without obstructing visibility. They can be easily customized with various heights and coatings, making them versatile for different environments.

5. Hog Wire Fencing

Hog wire fencing is another type of wire mesh specifically designed for agricultural uses. It consists of thick wire woven into a grid with larger openings, typically used to contain livestock, particularly hogs. This type of fence is highly durable and resistant to wear, capable of withstanding the elements and the pressure exerted by animals. Farmers and ranchers appreciate hog wire fencing for its functionality and longevity.

6. Screen Mesh

Screen mesh is often crafted from fine wire and is primarily used for screening applications, such as windows and doors. It helps keep insects out while allowing airflow into living spaces. The mesh can be made from various materials, including fiberglass, aluminum, and stainless steel. Screen mesh is available in different weaves and sizes to suit specific requirements, making it a staple in both residential and commercial architecture.

7. Monel Wire Mesh

Monel wire mesh is made from a nickel-copper alloy, providing exceptional resistance to corrosion and high temperatures. This type of wire mesh is ideal for use in marine environments, chemical processing, and industries where high strength and durability are required. Monel wire mesh is also used in filtration systems for oil, gas, and other harsh substances, making it a valuable material in specialized applications.

Conclusion

The variety of wire mesh types available caters to an extensive range of needs across different industries. From the strength of welded wire mesh to the versatility of screen mesh, each type serves a specific purpose while offering unique benefits. Understanding the different properties and applications of wire mesh can aid individuals and businesses in selecting the right type for their projects, ultimately enhancing performance and cost-effectiveness. Whether for construction, agriculture, or filtration, wire mesh remains an integral material with endless possibilities.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.