ਜਨਃ . 21, 2025 05:10

Back to list

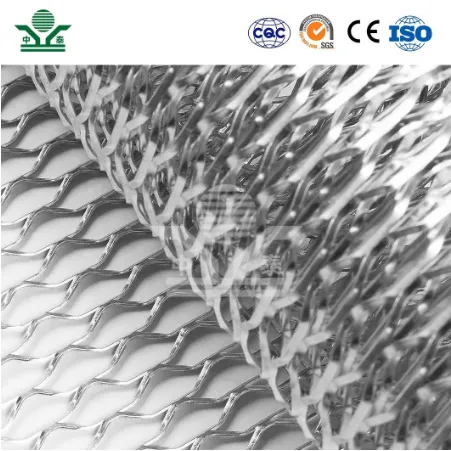

Floor Grating Stainless Steel China Manufacturers Car Grating

Purchasing steel grating can be an intricate process that benefits substantially from informed decision-making and professional insight. Steel grating is prized for its strength, durability, and versatility, making it an essential component in various industrial and commercial applications. Whether you're constructing walkways, platforms, or drainage covers, understanding the nuances of steel grating will enhance both the efficiency and safety of your project.

As you venture into purchasing steel grating, supplier credibility is imperative. Seek out manufacturers or distributors with a proven track record of quality and reliability. Investigating customer testimonials, industry certifications, and post-purchase support policies will provide insight into a supplier's trustworthiness and the quality of their products. Establishing a relationship with a well-regarded supplier can not only ensure high-quality materials but also offer ongoing support and guidance throughout your project’s duration. The environmental conditions where the steel grating will be installed are also factors to consider. In marine environments or areas with high salinity, the selection of stainless steel grating over carbon steel can prevent premature corrosion, thus extending the life of the installation. Similarly, harsh chemical exposures necessitate materials that can withstand such conditions without degrading or compromising performance. Cost versus value is a balance that cannot be ignored. While it might be tempting to opt for the least expensive product, consider the long-term implications of your choice. Higher initial investments in superior materials and craftsmanship often translate into lower maintenance costs and enhanced safety over the lifespan of the grating. Moreover, understanding the logistics involved in shipment and delivery of steel grating can prevent potential issues. Given the bulk and weight of grating materials, ensure your site has the capacity to efficiently receive and store shipments without delays, which could impede project timelines. Ultimately, purchasing steel grating is a decision that should leverage expertise, foresight, and careful examination of project needs. Recognizing the array of options and specifications, partnering with credible suppliers, and weighing cost against long-term value are all critical facets. When approached with diligence, the seamless integration of steel grating can enhance structural integrity, safety, and functionality in myriad applications, fulfilling both immediate and future project requirements optimally.

As you venture into purchasing steel grating, supplier credibility is imperative. Seek out manufacturers or distributors with a proven track record of quality and reliability. Investigating customer testimonials, industry certifications, and post-purchase support policies will provide insight into a supplier's trustworthiness and the quality of their products. Establishing a relationship with a well-regarded supplier can not only ensure high-quality materials but also offer ongoing support and guidance throughout your project’s duration. The environmental conditions where the steel grating will be installed are also factors to consider. In marine environments or areas with high salinity, the selection of stainless steel grating over carbon steel can prevent premature corrosion, thus extending the life of the installation. Similarly, harsh chemical exposures necessitate materials that can withstand such conditions without degrading or compromising performance. Cost versus value is a balance that cannot be ignored. While it might be tempting to opt for the least expensive product, consider the long-term implications of your choice. Higher initial investments in superior materials and craftsmanship often translate into lower maintenance costs and enhanced safety over the lifespan of the grating. Moreover, understanding the logistics involved in shipment and delivery of steel grating can prevent potential issues. Given the bulk and weight of grating materials, ensure your site has the capacity to efficiently receive and store shipments without delays, which could impede project timelines. Ultimately, purchasing steel grating is a decision that should leverage expertise, foresight, and careful examination of project needs. Recognizing the array of options and specifications, partnering with credible suppliers, and weighing cost against long-term value are all critical facets. When approached with diligence, the seamless integration of steel grating can enhance structural integrity, safety, and functionality in myriad applications, fulfilling both immediate and future project requirements optimally.

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP