Understanding Bar Grating Prices Factors That Influence Costs

Bar grating is a versatile and widely used material in various industrial applications, from flooring to drainage systems. Its unique design and robust properties make it an ideal choice for environments needing strength, durability, and safety. However, when it comes to purchasing bar grating, price becomes a significant factor for many buyers. In this article, we’ll explore the various elements that influence bar grating prices and offer insights to help you make informed purchasing decisions.

Material Composition

One of the primary determinants of bar grating prices is the material used in its construction. Common materials for bar grating include steel, aluminum, and fiberglass.

- Steel Grating This is the most common type of bar grating, known for its strength and affordability. It is typically made from carbon steel, which can be galvanized for increased corrosion resistance. The price of steel grating can vary based on market fluctuations in steel prices.

- Aluminum Grating While generally more expensive than steel, aluminum grating is lightweight and resistant to rust and corrosion. It’s often chosen for applications where weight is a concern or where the grating will be exposed to harsh chemicals.

- Fiberglass Grating Often regarded as a specialized option, fiberglass grating is non-corrosive and ideal for environments with chemicals or saltwater exposure. Prices for fiberglass can be on the higher end due to its unique properties and manufacturing process.

Manufacturing Process

The manufacturing process also impacts the cost of bar grating. There are two primary methods for producing bar grating

1. Welded Grating This involves the welding of load bars and crossbars, providing a heavy-duty structure that can withstand high loads. The manufacturing process can be time-intensive, which can increase costs.

2. Swaged Grating This method involves swaging the bearing bars into the cross bars, resulting in a lighter yet equally strong product. Swaged grating is often more cost-effective to produce, which can lower the overall price.

Grating Type

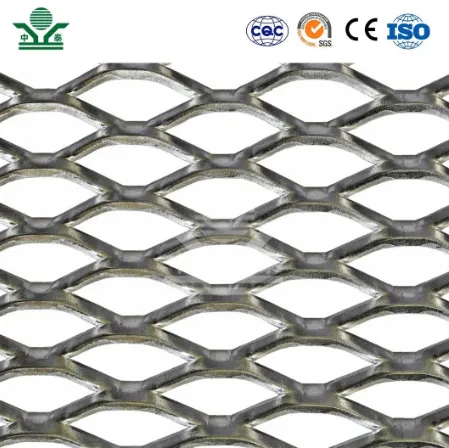

bar grating prices

There are different types of bar grating, including plain bar grating, serrated grating, and punched grating. The choice of type can significantly affect pricing

- Plain Bar Grating Simple and cost-effective, it is used in many applications but may lack the anti-slip feature that some environments require.

- Serrated Bar Grating The serrated edges provide increased traction, making it suitable for slippery conditions. This type may cost slightly more due to the additional manufacturing steps.

- Punched Grating Often used for decorative purposes or ventilation, punched grating may have a higher price point due to its custom designs.

Customization and Size

Customization also plays a key role in bar grating pricing. Standard sizes tend to be more affordable, as they are produced in bulk. However, many projects require custom dimensions or load capacities, which can lead to increased costs. Additionally, the thickness and spacing of the bars can also alter the final price.

Quantity and Order Size

When purchasing bar grating, the quantity ordered can significantly affect the price per unit. Bulk orders typically attract discounts, as manufacturers can reduce their production costs. Therefore, it’s advisable to consider your needs carefully and place larger orders if feasible to save on costs.

Shipping and Delivery

Finally, shipping and delivery charges can also impact the overall expense of purchasing bar grating. Due to its weight and size, transportation costs can be substantial. Many suppliers offer shipping deals for larger orders, so it’s worth inquiring about these options.

Conclusion

Understanding the factors that influence bar grating prices can empower buyers to make informed decisions. From material composition to customization and order size, each element plays a crucial role in determining the final cost. By carefully considering these aspects and exploring various suppliers, you can find the best option that meets both your budget and application needs. Whether you opt for steel, aluminum, or fiberglass, ensuring the right fit for your project is key to achieving optimal performance and safety.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.