ਜਨਃ . 20, 2025 07:57

Back to list

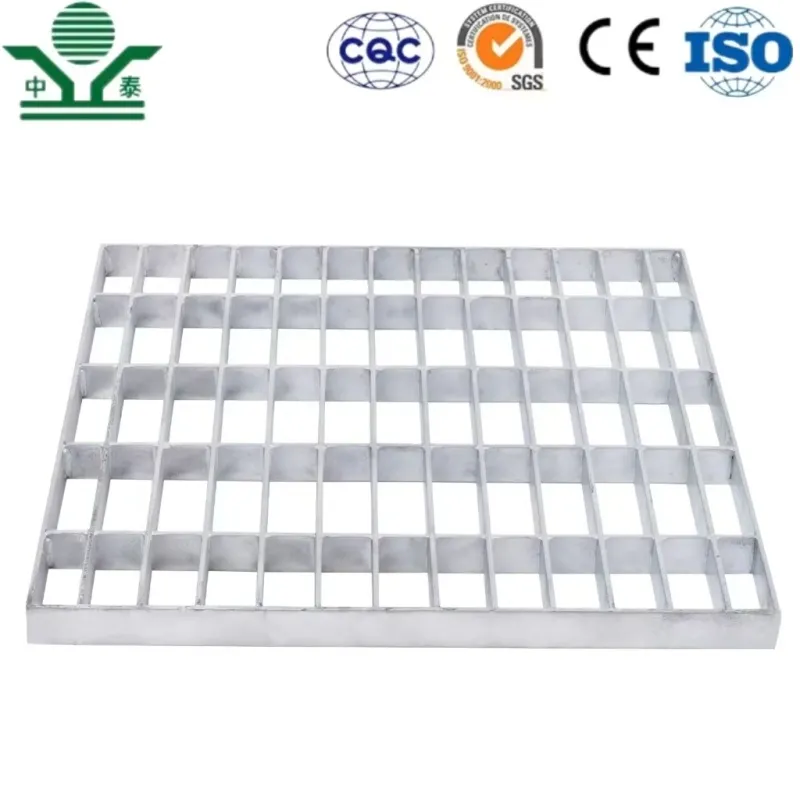

banded bar grating

Banded bar grating is a versatile and fundamental component in industrial settings, offering safety, durability, and functionality. This robust product is essential for numerous applications, from secure walkways in industrial plants to flooring in architectural projects. Understanding the advantages and applications of banded bar grating can enhance both the functionality and safety of any project.

Versatility is yet another key advantage offered by banded bar grating. Whether used in stair treads, trench covers, or ventilation grates, it adapts to various architectural and structural applications. Its ability to be custom-fabricated allows for tailored solutions that meet specific size, shape, and load-bearing requirements. This flexibility is invaluable in projects where standard solutions fall short. The eco-friendliness of banded bar grating should not be overlooked. Many grating products are manufactured in environmentally responsible ways, often using recycled materials. The long lifespan and recyclability at the end of its use contribute to sustainable building practices. A significant portion of choosing the right banded bar grating involves understanding the specific requirements of the application. Load demands, environmental conditions, and aesthetic preferences all play a role in determining the most suitable material and finish. For high-corrosion environments, stainless steel may be the best choice, while aluminum might be preferred for its lightweight properties in portable installations. An expert understanding of installation practices is essential to maximize the effectiveness of banded bar grating. Correct installation ensures that the grating provides the necessary support and safety. Engaging with experienced professionals during the planning and installation phases can help avoid costly errors and ensure compliance with relevant safety standards. In conclusion, banded bar grating is a critical component in many industrial and architectural projects, offering unmatched strength, safety, and adaptability. Its ability to accommodate diverse needs makes it indispensable for improving operational safety and efficiency. When selected and installed correctly, it provides a reliable and long-lasting solution, embodying the principles of strength and sustainability in modern construction.

Versatility is yet another key advantage offered by banded bar grating. Whether used in stair treads, trench covers, or ventilation grates, it adapts to various architectural and structural applications. Its ability to be custom-fabricated allows for tailored solutions that meet specific size, shape, and load-bearing requirements. This flexibility is invaluable in projects where standard solutions fall short. The eco-friendliness of banded bar grating should not be overlooked. Many grating products are manufactured in environmentally responsible ways, often using recycled materials. The long lifespan and recyclability at the end of its use contribute to sustainable building practices. A significant portion of choosing the right banded bar grating involves understanding the specific requirements of the application. Load demands, environmental conditions, and aesthetic preferences all play a role in determining the most suitable material and finish. For high-corrosion environments, stainless steel may be the best choice, while aluminum might be preferred for its lightweight properties in portable installations. An expert understanding of installation practices is essential to maximize the effectiveness of banded bar grating. Correct installation ensures that the grating provides the necessary support and safety. Engaging with experienced professionals during the planning and installation phases can help avoid costly errors and ensure compliance with relevant safety standards. In conclusion, banded bar grating is a critical component in many industrial and architectural projects, offering unmatched strength, safety, and adaptability. Its ability to accommodate diverse needs makes it indispensable for improving operational safety and efficiency. When selected and installed correctly, it provides a reliable and long-lasting solution, embodying the principles of strength and sustainability in modern construction.

Latest news

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP