Understanding the 3mm Perforated Sheet Applications and Benefits

Perforated sheets have become a staple in various industries due to their unique characteristics and versatility. Among the numerous sizes and types available, the 3mm perforated sheet stands out for its optimal balance between durability and functionality. This article delves into the features, applications, and advantages of using 3mm perforated sheets in different settings.

What is a 3mm Perforated Sheet?

A 3mm perforated sheet is typically constructed from various materials, including stainless steel, aluminum, and mild steel. The defining feature of this sheet is its consistent pattern of holes, which can vary in size, shape, and spacing. The “3mm” designation indicates the thickness of the sheet, which enhances its strength and resistance to impact and wear.

The perforation process involves creating precise holes using methods like punching or laser cutting. The resulting sheet retains structural integrity while offering a range of functionalities, such as airflow, light transmission, and aesthetic appeal.

Applications of 3mm Perforated Sheets

One of the primary benefits of 3mm perforated sheets is their broad applicability across various industries. Here are some noteworthy applications

1. Architecture and Interior Design 3mm perforated sheets are often used in the design of building facades, partitions, and ceilings. They provide stylish decor elements while allowing for ventilation and natural light. Designers appreciate their ability to create striking visual patterns without sacrificing structural strength.

2. Industrial Uses In industrial settings, these perforated sheets are employed in machinery guards, conveyor belts, and filtration systems. Their holes can efficiently allow the passage of air or liquids while protecting workers and equipment from potential hazards.

3. Automotive Sector The automotive industry utilizes perforated sheets for components such as grilles and acoustic panels. These parts must endure varying environmental conditions, and the robust nature of a 3mm sheet ensures longevity and performance.

4. Furniture Manufacturing The design of modern furniture often incorporates perforated materials for aesthetics and ventilation. Seats, backs, and shelves made from 3mm perforated sheets are not only visually appealing but also lightweight and easy to handle.

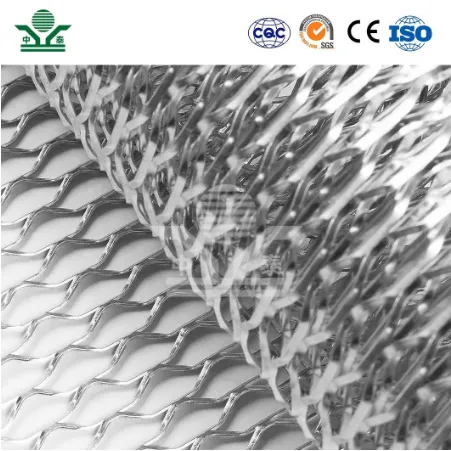

3mm perforated sheet

5. Soundproofing Due to the way sound waves interact with perforated materials, these sheets are increasingly used in soundproofing applications. They can help reduce noise levels in public spaces, recording studios, and residential buildings while contributing to a trendy design.

Advantages of Using 3mm Perforated Sheets

The benefits of using 3mm perforated sheets extend beyond mere functionality. Here are some significant advantages

1. Durability The 3mm thickness provides enhanced durability compared to thinner alternatives, making it suitable for high-stress applications.

2. Versatility With customizable hole patterns and sizes, these sheets can be tailored to meet specific project requirements. This versatility makes them ideal for various uses across multiple industries.

3. Ease of Maintenance Perforated sheets are easy to clean and maintain, making them suitable for environments that require high hygiene standards, such as food processing facilities.

4. Aesthetics The aesthetic appeal of perforated sheets makes them a popular choice for designers looking to create modern and contemporary spaces.

5. Weight Efficiency Despite their strength, 3mm perforated sheets remain relatively lightweight. This characteristic is essential in applications where weight reduction is critical, such as in the aerospace and automotive industries.

Conclusion

In summary, the 3mm perforated sheet serves as a versatile and durable solution across various industrial and creative applications. Its ability to combine functionality with aesthetics makes it an invaluable resource for architects, engineers, and designers alike. As industries continue to evolve, the relevance of 3mm perforated sheets will undoubtedly persist, showcasing their enduring appeal and practical uses.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.