Expanded metal mesh has made significant inroads into various sectors due to its versatility and strength. Understanding the different types of expanded metal mesh available can significantly benefit industries ranging from construction to manufacturing. Specialized for different applications, the choice of expanded metal mesh type can influence the efficiency and effectiveness of a project.

First, there is standard expanded metal, which is made by slitting and stretching a metal sheet to create diamond-shaped openings. This type is widely used in walkways, platforms, and fencing due to its durability and excellent grip underfoot. The diamond pattern increases strength while minimizing weight, making it a popular choice for industrial settings where safety and reliability are paramount.

Next, flattened expanded metal takes standard expanded metal one step further. After the slitting and stretching process, the mesh is run through a cold rolling press, providing a smoother and flatter surface. This not only improves the material's aesthetic appeal but also makes it more suitable for applications requiring a more refined look, such as architectural facades, interior design, and certain automotive components. The flattening process does not compromise the material's structural integrity, which still benefits from increased rigidity and load-bearing capability.

Moving on to micro-expanded metal, this variety boasts smaller openings and finer strands compared to standard expanded types. This makes it particularly useful in filtering applications where precision is critical, such as in air or water filtration systems. Micro-expanded metal can also be found in speaker grilles and small machinery guards, where its fine structure does not impede performance while offering protection or containment.

types of expanded metal mesh

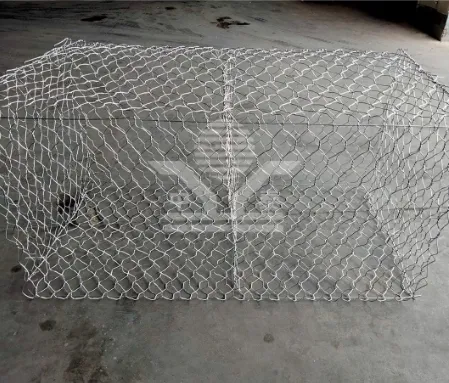

Grating expanded metal is another variant, designed predominantly for load-bearing applications. Characterized by thicker strands and a heavier gauge, grating expanded metal provides substantial strength and durability. It is typically used in industrial flooring, mezzanines, or any platform requiring high load tolerance. The spacing between the strands ensures excellent drainage and light passage, making it ideal for outdoor or moist environments.

For those seeking to balance visibility with containment, decorative expanded metal mesh offers innovative solutions. These meshes come in various patterns ranging from traditional to contemporary designs, perfect for grilles, partitions, and screen facades. They bring a unique aesthetic dimension to the table while maintaining functional benefits like rigidity and support.

In specialized environments, there exists a need for architectural expanded metal mesh. This variant is engineered not only for its structural qualities but also for its visual impact. Used in both exterior and interior design, architectural meshes can be crafted into complex geometrical shapes, enabling architects and designers to realize virtually any vision. Offering ample room for light and air flow without sacrificing structural integrity, architectural meshes define modern building aesthetics.

In conclusion, expanded metal mesh is an indispensable material that adapts to diverse needs across several industries. The choice between standard, flattened, micro, grating, decorative, and architectural meshes hinges on the specific application requirements, such as strength, appearance, and function. A thorough understanding of each type's characteristics and advantages can improve project outcomes, maximize safety, and enhance design, providing comprehensive solutions to contemporary engineering and aesthetic challenges. As innovation continues to push the boundaries of material science, expanded metal meshes will undoubtedly evolve, offering even more possibilities and efficiencies in the future.

-

Trusted Expanded Metal Mesh For All Projects

NewsMay.08,2025

-

Stainless Steel Expanded Metal for Versatile Uses

NewsMay.08,2025

-

Reliable Steel Grating Choices

NewsMay.08,2025

-

Perforated Sheet Metal for Every Need

NewsMay.08,2025

-

Heavy Duty Expanded Metal Mesh for Robust Solutions

NewsMay.08,2025

-

Expanded Aluminum Metal for Versatile Applications

NewsMay.08,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.