feb . 02, 2025 05:53

Back to list

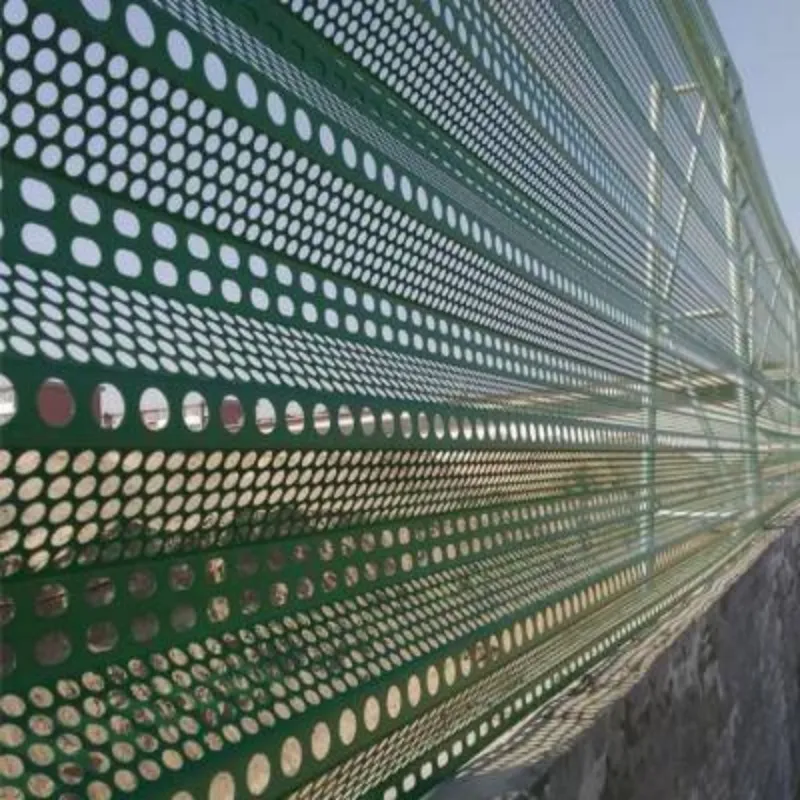

0.8mm Perforated Metal Mesh Screen China Wholesalers Iron Perforated Sheet

Perforated slotted metal sheets have emerged as a crucial element across numerous industries, providing unparalleled versatility and functionality. In terms of experience, these metal sheets are frequently used in sectors such as construction, automotive, agriculture, and filtration systems, showcasing a vast range of applications that make them invaluable.

Additionally, many manufacturers offer certificates of compliance, further establishing trust with engineers and designers who rely on these materials for structural and functional integrity. These certifications are a testament to the rigorous quality control processes that underpin the production of perforated metal sheets—an essential factor in industries where reliability cannot be compromised. Trustworthiness is further reinforced through case studies and client testimonials highlighting successful projects utilizing perforated slotted metal sheets. From enhancing acoustic properties in auditoriums to creating efficient air filtration systems, these examples provide empirical evidence of the product’s effectiveness. Professionals from various sectors have shared positive feedback regarding the ease of installation, longevity, and the overall contribution of these sheets to project success. Clear documentation and transparent engagement from suppliers also play a significant role in nurturing trust. By offering detailed product information, comprehensive installation guides, and post-sales support, manufacturers underline their commitment to customer satisfaction. This transparency helps in making informed decisions, ensuring users choose the right type of perforated slotted metal sheet for their specific application needs. In conclusion, perforated slotted metal sheets stand as a testament to well-engineered industrial design. Their diverse applications, backed by expert manufacturing and authoritative endorsements, make them a reliable choice across multiple domains. By embodying expertise and building trust through proven performance, these metal sheets remain an essential component in modern engineering solutions.

Additionally, many manufacturers offer certificates of compliance, further establishing trust with engineers and designers who rely on these materials for structural and functional integrity. These certifications are a testament to the rigorous quality control processes that underpin the production of perforated metal sheets—an essential factor in industries where reliability cannot be compromised. Trustworthiness is further reinforced through case studies and client testimonials highlighting successful projects utilizing perforated slotted metal sheets. From enhancing acoustic properties in auditoriums to creating efficient air filtration systems, these examples provide empirical evidence of the product’s effectiveness. Professionals from various sectors have shared positive feedback regarding the ease of installation, longevity, and the overall contribution of these sheets to project success. Clear documentation and transparent engagement from suppliers also play a significant role in nurturing trust. By offering detailed product information, comprehensive installation guides, and post-sales support, manufacturers underline their commitment to customer satisfaction. This transparency helps in making informed decisions, ensuring users choose the right type of perforated slotted metal sheet for their specific application needs. In conclusion, perforated slotted metal sheets stand as a testament to well-engineered industrial design. Their diverse applications, backed by expert manufacturing and authoritative endorsements, make them a reliable choice across multiple domains. By embodying expertise and building trust through proven performance, these metal sheets remain an essential component in modern engineering solutions.

Latest news

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP