Understanding the Measure of Square Mesh A Comprehensive Overview

In various fields, particularly in engineering, architecture, and environmental science, the term square mesh represents a critical concept. The measure of square mesh plays a significant role in defining the parameters of construction materials, filtration systems, and netting products. This article explores the definition of square mesh, its measurements, relevant applications, and how to determine its appropriate size for specific uses.

Definition of Square Mesh

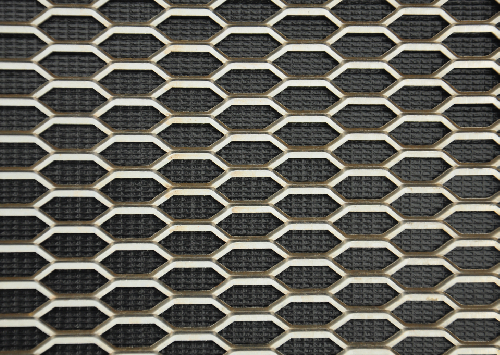

Square mesh refers to a grid structure made of square openings of uniform size. This type of mesh is commonly found in metals, plastics, or fabrics, with the squares serving a multitude of functions. The size of the square, or mesh opening, is a vital characteristic, influencing how the mesh performs in its intended application.

Measuring Square Mesh

The measure of square mesh is typically quantified by the size of its opening and the thickness of the material used. The most common measurements include the width of each square (opening size) and the gauge or thickness of the wire or material. Opening sizes can range from very small (measured in micrometers) to substantially larger openings suitable for heavy-duty applications.

Mesh size is usually denoted in inches or millimeters, often expressed in terms such as 1/4 inch, 1 mm, or 10 mesh, where the number denotes the number of openings per inch. For example, 10 mesh indicates that there are 10 openings per inch, resulting in approximately a 0.0787-inch square opening.

Applications of Square Mesh

Square mesh is versatile and finds applications across different industries

what is the measure of the square mesh

2. Filtration Square mesh is also typical in filtration systems, including water treatment facilities and various industrial processes. The mesh's opening size determines the size of particles it can filter, making it crucial to select the appropriate mesh for specific filtration requirements.

3. Agriculture In agriculture, square mesh is used in fencing, animal enclosures, and crop protection. The mesh's size helps protect crops from pests while allowing sunlight and water to penetrate.

4. Manufacturing In manufacturing, square mesh can be used in sorting, sifting, and separation processes. It helps to categorize materials based on size during production analytics.

5. Safety and Security Square mesh is often used in safety barriers, screens, and grates. The design helps to maintain safety standards while providing visibility and ventilation.

Selecting the Right Mesh Size

Choosing the appropriate measure of square mesh requires a thorough understanding of the intended use and the conditions it will face. For instance, if the mesh is intended for filtration, the particle size and flow rate are critical factors in determining the optimal opening size. Conversely, for structural applications, one needs to consider the load the mesh will bear and select a thickness that can withstand the stress without compromising integrity.

Factors such as environmental exposure, chemical resistance, and ease of cleaning should also guide the decision-making process. Standards and guidelines established by organizations in relevant industries can further assist in determining the ideal mesh specifications.

Conclusion

The measure of square mesh is essential in many sectors, impacting functionality, safety, and performance. By understanding the properties and appropriate uses of square mesh, professionals across various fields can make informed decisions that enhance the efficiency and reliability of their projects. Whether in construction, filtration, agriculture, or manufacturing, selecting the right square mesh enhances structural integrity and operational effectiveness, underscoring its significance in both everyday applications and specialized operations.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.