Jan . 20, 2025 03:44

Back to list

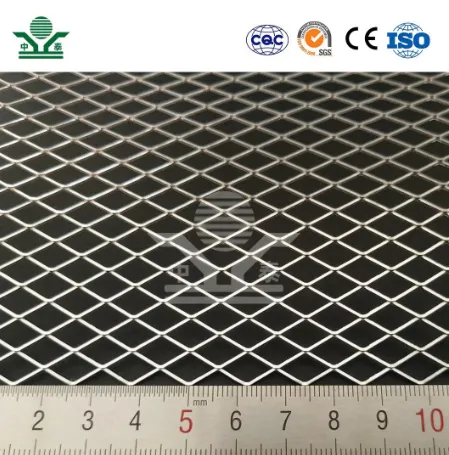

Traffic Trench Drain Grate China Manufacturing Metal Security Window Grates

Welded grating is a versatile and robust solution for a myriad of industrial applications, known for its unmatched strength and durability. As an experienced professional in the metal fabrication industry, I have witnessed the transformative impact that this product can have on project outcomes. Welded grating offers exceptional load-bearing properties, making it an indispensable component in architectural and industrial design.

Corrosion resistance is another critical factor that enhances the credibility of welded grating as a superior choice. Galvanizing techniques or the use of stainless steel in manufacturing ensure the grating can withstand corrosive environments, such as marine locations or chemical exposure. This resistance to corrosion not only protects the grating itself but also shields the underlying structure from potential damage, guaranteeing a long-term, cost-effective solution. Environmental responsibility signifies an emerging focus in modern industrial practices. Welded grating boasts recyclable properties, aligning with sustainable development goals and reducing environmental impact. Engaging with welded grating adheres to eco-friendly practices, showing a commitment to responsible resource management. Finally, relying on welded grating endows projects with an authoritative stamp due to its compliance with international safety and quality standards. My expertise has taught me that these accolades resonate well within industry circles, instilling confidence among stakeholders and clients alike. When choosing a material with high trustworthiness, welded grating unequivocally meets the stringent criteria that experienced professionals and beginners alike should seek. In conclusion, welded grating is more than a material; it embodies a reliable solution engineered to meet the demanding needs of a modern industrial environment. Its robust properties, customizable options, and steadfast safety features make it a leading choice for industry experts aiming to enhance both functionality and safety in their projects.

Corrosion resistance is another critical factor that enhances the credibility of welded grating as a superior choice. Galvanizing techniques or the use of stainless steel in manufacturing ensure the grating can withstand corrosive environments, such as marine locations or chemical exposure. This resistance to corrosion not only protects the grating itself but also shields the underlying structure from potential damage, guaranteeing a long-term, cost-effective solution. Environmental responsibility signifies an emerging focus in modern industrial practices. Welded grating boasts recyclable properties, aligning with sustainable development goals and reducing environmental impact. Engaging with welded grating adheres to eco-friendly practices, showing a commitment to responsible resource management. Finally, relying on welded grating endows projects with an authoritative stamp due to its compliance with international safety and quality standards. My expertise has taught me that these accolades resonate well within industry circles, instilling confidence among stakeholders and clients alike. When choosing a material with high trustworthiness, welded grating unequivocally meets the stringent criteria that experienced professionals and beginners alike should seek. In conclusion, welded grating is more than a material; it embodies a reliable solution engineered to meet the demanding needs of a modern industrial environment. Its robust properties, customizable options, and steadfast safety features make it a leading choice for industry experts aiming to enhance both functionality and safety in their projects.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP