The Importance of Thin Metal Sheets with Holes in Modern Engineering

In the realm of modern engineering and manufacturing, the use of thin metal sheets with holes has become increasingly prevalent. These materials serve a myriad of functions across various industries, from aerospace to electronics, and their versatility makes them indispensable in contemporary applications. This article explores the significance of thin metal sheets with holes, their production processes, and their diverse uses.

Thin metal sheets, typically made from materials such as aluminum, stainless steel, or copper, offer a lightweight yet strong solution for numerous applications. The incorporation of holes into these sheets creates a unique structure that enhances their functionality. The process of creating holes can be achieved through methods such as punching, stamping, or laser cutting, allowing for precision and customization according to specific requirements.

The Importance of Thin Metal Sheets with Holes in Modern Engineering

Moreover, the design of holes can serve various purposes, such as ventilation, drainage, and aesthetic appeal. In the construction industry, architects frequently employ perforated metal sheets to create visually striking facades while ensuring adequate air circulation. These sheets can be used in sunshades, helping to regulate indoor temperatures and contribute to energy efficiency in buildings.

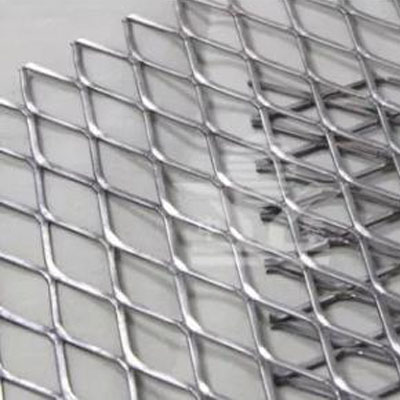

thin metal sheet with holes

In the electronics sector, thin metal sheets with holes play a crucial role in the manufacturing of circuit boards and heat shields. The precise placement of holes facilitates the dissipation of heat generated by electronic components, ensuring their longevity and reliability. Additionally, these sheets are often utilized in creating enclosures that protect sensitive electronic devices from dust and moisture.

The automotive industry also benefits significantly from the use of thin metal sheets with holes. Manufacturers utilize them for various components, such as grills, heat shields, and other structural parts, where weight reduction is critical. The ability to customize hole sizes and patterns allows for tailored designs that enhance performance, safety, and overall vehicle aesthetics.

In the realm of sustainability, thin metal sheets with holes can contribute to eco-friendly practices. For example, these materials can be used in the design of efficient filtration systems in water treatment facilities. The perforations in the sheets enhance the filtration process, promoting cleaner water while reducing material waste. Furthermore, many manufacturers are now adopting techniques that utilize recycled metals, further minimizing the environmental impact of production processes.

As industries continue to evolve, the demand for innovative applications of thin metal sheets with holes is likely to increase. Advancements in manufacturing technologies, such as 3D printing and CNC machining, are expected to revolutionize how these materials are designed and produced. The ability to create complex shapes and intricate hole patterns with precision could open up new avenues for engineers and designers, fostering innovation across various sectors.

In conclusion, thin metal sheets with holes represent a vital material in modern engineering, offering a combination of strength, lightweight properties, and versatility. Their applications span multiple industries, from aerospace to construction and electronics, showcasing their integral role in advancing technology and design. As we move toward a more sustainable future, the ongoing development and utilization of these materials will undoubtedly contribute to improved efficiency and environmental responsibility in manufacturing practices.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.