Feb . 01, 2025 01:10

Back to list

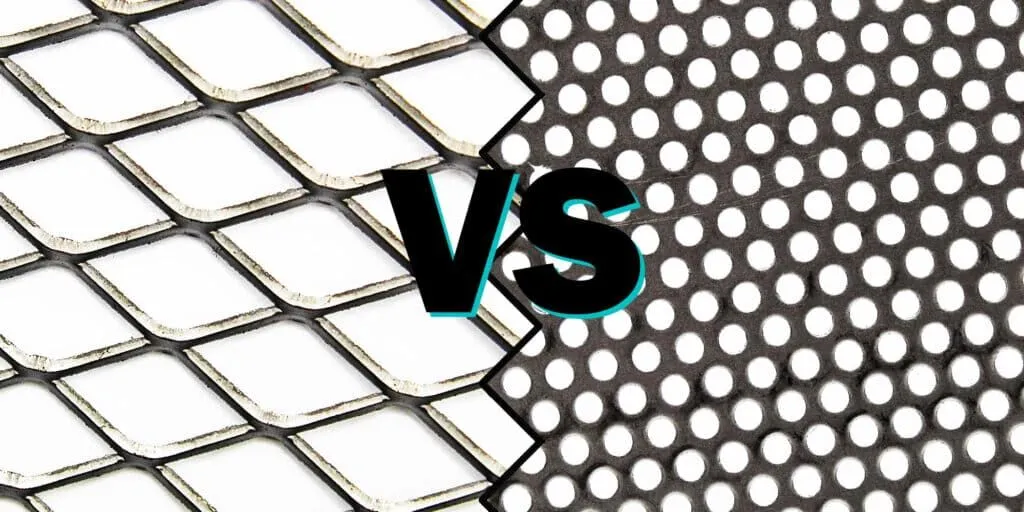

thin metal sheet with holes

The evolving technology of thin metal sheets with holes is revolutionizing numerous industries, thanks to their exceptional versatility and diverse applications. These sheets, commonly known as perforated metal sheets, have found their place in sectors including architecture, automotive, environmental engineering, and more, owing to their unique properties.

Trust in the reliability of perforated metal sheets stems from their well-documented success across different applications. Their longevity, durability, and cost-effectiveness are proven in various industries. Whether it is a construction company engaging them for building facades or a manufacturer using them for machinery parts, the historical efficacy of these sheets fosters confidence. Trustworthiness is further reinforced by industry standards and certifications that validate the quality and perfection of these sheets. In terms of product development and usage, experience is key to leveraging the full potential of thin metal sheets with holes. Manufacturers constantly innovate to improve perforation techniques, creating more refined and customized solutions. The advent of laser technology and computerized numerical control (CNC) machinery has transformed traditional manufacturing, allowing for more precise and intricate perforations. Professionals in the field share experiences that these advancements have significantly expanded the possibilities of using these sheets, leading to more sophisticated and efficient designs. Moreover, the adaptability of these sheets to various coatings and finishes enhances their applicability. Depending on the environmental conditions and desired aesthetic appeal, sheets can be anodized, powder-coated, or galvanized. These treatments protect against corrosion, improve surface hardness, and provide a range of color options, aligning with the specific needs of each application. Expertise in material science is critical when opting for these enhancements to ensure compatibility and durability. From a sustainability perspective, perforated metal sheets align with eco-friendly practices. They are often manufactured from recyclable materials, and their lightweight nature reduces transportation emissions compared to heavier alternatives. Additionally, by contributing to energy efficiency in buildings and effective filtration in environmental systems, they play a substantial role in promoting sustainable developments. In conclusion, thin metal sheets with holes are more than just structural elements; they are a convergence of experience, expertise, authoritativeness, and trustworthiness. As industries continue to push the boundaries of innovation, these sheets will undoubtedly remain integral, adapting to emerging demands and supporting a sustainable future.

Trust in the reliability of perforated metal sheets stems from their well-documented success across different applications. Their longevity, durability, and cost-effectiveness are proven in various industries. Whether it is a construction company engaging them for building facades or a manufacturer using them for machinery parts, the historical efficacy of these sheets fosters confidence. Trustworthiness is further reinforced by industry standards and certifications that validate the quality and perfection of these sheets. In terms of product development and usage, experience is key to leveraging the full potential of thin metal sheets with holes. Manufacturers constantly innovate to improve perforation techniques, creating more refined and customized solutions. The advent of laser technology and computerized numerical control (CNC) machinery has transformed traditional manufacturing, allowing for more precise and intricate perforations. Professionals in the field share experiences that these advancements have significantly expanded the possibilities of using these sheets, leading to more sophisticated and efficient designs. Moreover, the adaptability of these sheets to various coatings and finishes enhances their applicability. Depending on the environmental conditions and desired aesthetic appeal, sheets can be anodized, powder-coated, or galvanized. These treatments protect against corrosion, improve surface hardness, and provide a range of color options, aligning with the specific needs of each application. Expertise in material science is critical when opting for these enhancements to ensure compatibility and durability. From a sustainability perspective, perforated metal sheets align with eco-friendly practices. They are often manufactured from recyclable materials, and their lightweight nature reduces transportation emissions compared to heavier alternatives. Additionally, by contributing to energy efficiency in buildings and effective filtration in environmental systems, they play a substantial role in promoting sustainable developments. In conclusion, thin metal sheets with holes are more than just structural elements; they are a convergence of experience, expertise, authoritativeness, and trustworthiness. As industries continue to push the boundaries of innovation, these sheets will undoubtedly remain integral, adapting to emerging demands and supporting a sustainable future.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP