Feb . 05, 2025 04:00

Back to list

round hole perforated stainless steel sheet

Steel perforated sheet metal is more than just a versatile architectural material; it is a fundamental component in numerous industrial applications, prized for its combination of durability, design flexibility, and functionality. As someone deeply embedded in the field of materials engineering, I have witnessed firsthand how transformative perforated metal sheets can be for both aesthetic and practical implementations.

Further bolstering the credibility and trustworthiness of steel perforated sheet metal is its contribution to sustainability. With a focus on reducing environmental impact, many manufacturers prioritize recycling and reusing materials, ensuring that waste is minimized. The innate longevity and recyclability of steel underline its environmental credentials, reinforcing its status as a material of choice in green building practices. In industrial applications, perforated steel sheets excel in filtration, acoustics, and ventilation. Their use in air conditioning systems, oil filters, and soundproofing solutions is a testament to their versatility and performance reliability. Engineers and project managers can rely on these sheets not only to meet but exceed their performance specifications, reducing maintenance costs and downtime, thus verifying their authority as a high-performance material solution. To close, steel perforated sheet metal stands as a paragon of modern material advancement, underscored by its expert-driven applications, proven performance, and an authoritative standing in sustainability. For anyone looking to leverage its benefits, understanding its wide range of applications can ensure optimal implementation, maximizing return on investment across countless projects. As industry advancements continue, the adaptability and efficacy of perforated steel sheets remain pivotal, offering both classic utility and cutting-edge design possibilities.

Further bolstering the credibility and trustworthiness of steel perforated sheet metal is its contribution to sustainability. With a focus on reducing environmental impact, many manufacturers prioritize recycling and reusing materials, ensuring that waste is minimized. The innate longevity and recyclability of steel underline its environmental credentials, reinforcing its status as a material of choice in green building practices. In industrial applications, perforated steel sheets excel in filtration, acoustics, and ventilation. Their use in air conditioning systems, oil filters, and soundproofing solutions is a testament to their versatility and performance reliability. Engineers and project managers can rely on these sheets not only to meet but exceed their performance specifications, reducing maintenance costs and downtime, thus verifying their authority as a high-performance material solution. To close, steel perforated sheet metal stands as a paragon of modern material advancement, underscored by its expert-driven applications, proven performance, and an authoritative standing in sustainability. For anyone looking to leverage its benefits, understanding its wide range of applications can ensure optimal implementation, maximizing return on investment across countless projects. As industry advancements continue, the adaptability and efficacy of perforated steel sheets remain pivotal, offering both classic utility and cutting-edge design possibilities.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

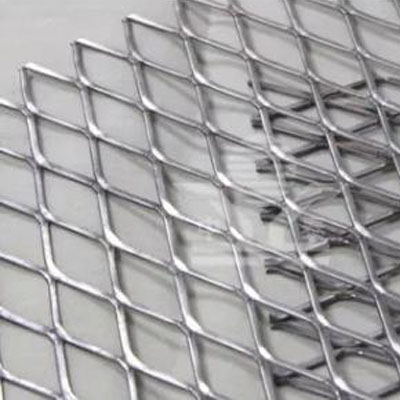

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP