Understanding Steel Grating Thickness An Overview

Steel grating is a crucial material used across various industries for a multitude of applications. From flooring to walkways, its structural integrity, durability, and weight-bearing capacity make it an ideal choice for both industrial and commercial environments. One of the essential factors to consider when selecting steel grating is its thickness. This article delves into why thickness matters and how to determine the appropriate thickness for specific applications.

The Importance of Grating Thickness

The thickness of steel grating is a primary contributor to its strength and durability. Thicker grating can support more weight and withstand harsher conditions. Conversely, thinner grating is lighter and may be more suitable for applications where weight is a critical factor, such as on elevated platforms or in temporary structures.

Choose the right thickness based on the intended application. For instance, heavy industrial environments—such as manufacturing plants, warehouses, or oil rigs—typically require thicker grating to endure constant foot traffic, heavy equipment loads, and exposure to corrosive substances.

Common Thickness Options

Steel grating comes in various thickness options, usually ranging from 1/4 inch (6 mm) to 1 inch (25 mm), but custom thicknesses can also be produced. The choice of thickness ultimately depends on several factors

1. Load Bearing Capacity One of the primary considerations is the load the grating must support. Thicker grating can handle greater loads, which is vital for applications involving heavy machinery or vehicular traffic.

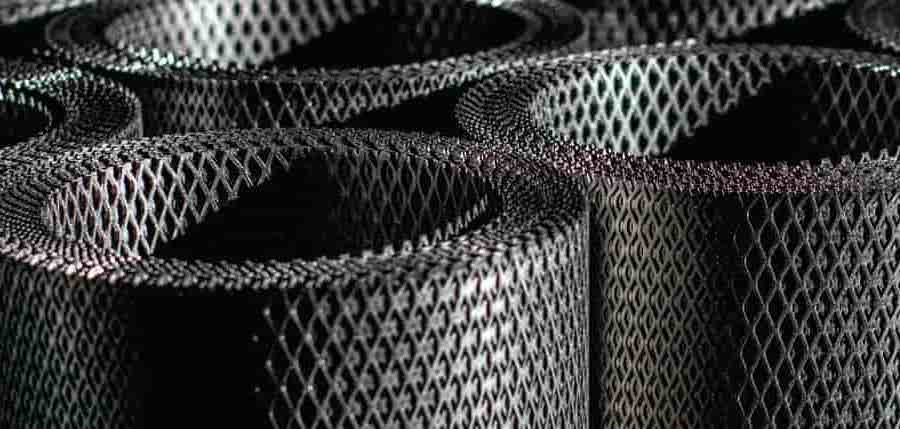

steel grating thickness

2. Span Distance The distance between supporting beams is another critical factor. Greater spans require thicker grating to prevent bending and warping under load. For example, if grating must span a distance of several feet without support, a thicker profile may be necessary.

3. Environmental Conditions The environment in which the grating will be used can influence thickness. Areas prone to extreme weather, aggressive chemicals, or heavy foot traffic may necessitate a thicker, more robust grating solution to ensure longevity.

4. Aesthetic Considerations In some applications, the appearance of the grating may play a role in thickness selection. Thicker grating may offer a more substantial, industrial look that some architects prefer for façade applications, while thinner options may be more streamlined for modern designs.

Standards and Regulations

When selecting steel grating thickness, it's essential to comply with local building codes and industry standards. Organizations like the American National Standards Institute (ANSI) have established guidelines to ensure safety and performance in different applications. Checking these standards can help ensure that the chosen thickness not only meets user needs but also adheres to safety regulations.

Conclusion

In conclusion, steel grating thickness is a fundamental consideration that influences the performance, safety, and suitability of grating for various applications. Whether in heavy industrial settings or architectural designs, understanding the implications of thickness can lead to more informed decisions that enhance the functionality and endurance of the structures involved. As industries evolve, the demand for customized solutions increases, emphasizing the importance of tailored thickness options to meet diverse needs. Always consult with experts and refer to standards to make the best choice for your specific requirements.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.