Jan . 20, 2025 05:30

Back to list

steel grating heavy duty

Choosing the right materials for industrial projects is crucial, with steel grating heavy duty emerging as a pivotal solution for load-bearing applications. This robust material has evolved significantly, offering unmatched durability and versatility—a must-have for those in industries such as construction, manufacturing, and transportation who demand reliability.

Furthermore, the authoritative nature of steel grating heavy duty is well-documented through its widespread endorsement by industry leaders. For instance, in large-scale public projects, it is frequently the material of choice, extensively tested and proven in the most demanding conditions. This broad acceptance is a testament to its reliability, which stakeholders consider invaluable. Understanding these attributes also means recognizing how steel grating heavy duty supports sustainability initiatives. Modern production techniques emphasize the use of recycled steel, significantly reducing environmental impact while maintaining quality. Thus, choosing steel grating heavy duty aligns with responsible construction practices, an important consideration for companies looking to bolster their environmental credibility. Trustworthiness is another key factor that bolsters the appeal of steel grating heavy duty in industrial applications. Manufacturers maintain rigorous quality control processes, ensuring that each unit meets both specification and customer expectations. For purchasers, this attention to detail translates into reliable performance and returns on investment. It also establishes robust supplier relationships, as buyers are confident they will consistently receive high-grade materials. In conclusion, for those tasked with selecting heavy-duty materials capable of withstanding extreme conditions, steel grating heavy duty stands out as an unparalleled choice backed by experience, expertise, authoritativeness, and trustworthiness. Its balance of strength, versatility, and environmental consideration makes it a staple in industry applications. As demands evolve, so too does this material, continually meeting the challenges of modern infrastructure with innovative solutions and unmatched reliability.

Furthermore, the authoritative nature of steel grating heavy duty is well-documented through its widespread endorsement by industry leaders. For instance, in large-scale public projects, it is frequently the material of choice, extensively tested and proven in the most demanding conditions. This broad acceptance is a testament to its reliability, which stakeholders consider invaluable. Understanding these attributes also means recognizing how steel grating heavy duty supports sustainability initiatives. Modern production techniques emphasize the use of recycled steel, significantly reducing environmental impact while maintaining quality. Thus, choosing steel grating heavy duty aligns with responsible construction practices, an important consideration for companies looking to bolster their environmental credibility. Trustworthiness is another key factor that bolsters the appeal of steel grating heavy duty in industrial applications. Manufacturers maintain rigorous quality control processes, ensuring that each unit meets both specification and customer expectations. For purchasers, this attention to detail translates into reliable performance and returns on investment. It also establishes robust supplier relationships, as buyers are confident they will consistently receive high-grade materials. In conclusion, for those tasked with selecting heavy-duty materials capable of withstanding extreme conditions, steel grating heavy duty stands out as an unparalleled choice backed by experience, expertise, authoritativeness, and trustworthiness. Its balance of strength, versatility, and environmental consideration makes it a staple in industry applications. As demands evolve, so too does this material, continually meeting the challenges of modern infrastructure with innovative solutions and unmatched reliability.

Next:

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

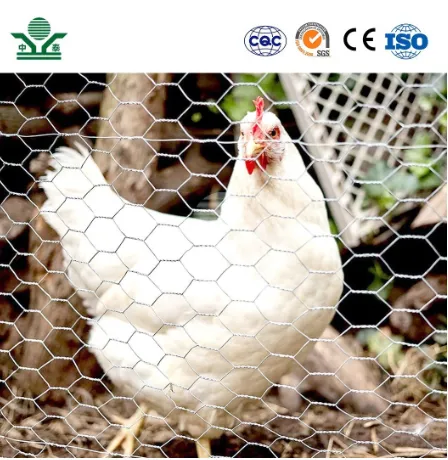

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP