Jan . 17, 2025 04:50

Back to list

Zhongtai Circular Steel Grating Trench Drain Covers China Factory Manhole Covers and Gratings

Elevating effective infrastructure solutions often means focusing on efficient drainage systems. Steel grating for drainage purposes offers an exceptional blend of durability and reliability that is unmatched by conventional drainage solutions. This article delves into the transformative benefits of using steel grating for drainage systems, driven by real-world experiences, professional insights, and acknowledged authority in the field.

Trust in steel grating as a drainage solution is supported by extensive manufacturer guarantees, some of which extend for upwards of 25 years. These warranties are not idle promises but are backed by comprehensive research and field testing. As environmental sustainability becomes ever more critical, the recyclability of steel further enhances its trustworthiness. Post-consumer recycling of steel gratings aligns with global sustainability goals, reducing the ecological footprint of drainage projects. Commercial and residential developers alike stand to gain from incorporating steel grating into their drainage designs. Its adaptability to various architectural styles, combined with a range of customizable options such as size adjustments and surface coatings, ensures that steel grating can meet the diverse demands of any project. Whether it is for a high-capacity parking structure or a landscaped urban park, the benefits of employing steel grating are clear and compelling. Moreover, industry experts are continually exploring innovative applications for steel grating in drainage systems, driven by evolving environmental regulations and consumer expectations. Modern grading can incorporate slip-resistant surfaces and corrosion-resistant coatings, enhancing safety and extending utility in even the most extreme conditions. This adaptability speaks volumes about the forward-thinking nature of the steel grating industry, which consistently strives to meet and set new industry benchmarks. In conclusion, steel grating for drainage is not merely a byword in civil engineering and construction circles; it is a defining characteristic. Its contribution to efficient, durable, and sustainable drainage systems is significant, with a basis in both historical data and future-forward thinking. Whether through documented expertise or the rigorous trust placed in its performance, steel grating remains a cornerstone of effective drainage solutions.

Trust in steel grating as a drainage solution is supported by extensive manufacturer guarantees, some of which extend for upwards of 25 years. These warranties are not idle promises but are backed by comprehensive research and field testing. As environmental sustainability becomes ever more critical, the recyclability of steel further enhances its trustworthiness. Post-consumer recycling of steel gratings aligns with global sustainability goals, reducing the ecological footprint of drainage projects. Commercial and residential developers alike stand to gain from incorporating steel grating into their drainage designs. Its adaptability to various architectural styles, combined with a range of customizable options such as size adjustments and surface coatings, ensures that steel grating can meet the diverse demands of any project. Whether it is for a high-capacity parking structure or a landscaped urban park, the benefits of employing steel grating are clear and compelling. Moreover, industry experts are continually exploring innovative applications for steel grating in drainage systems, driven by evolving environmental regulations and consumer expectations. Modern grading can incorporate slip-resistant surfaces and corrosion-resistant coatings, enhancing safety and extending utility in even the most extreme conditions. This adaptability speaks volumes about the forward-thinking nature of the steel grating industry, which consistently strives to meet and set new industry benchmarks. In conclusion, steel grating for drainage is not merely a byword in civil engineering and construction circles; it is a defining characteristic. Its contribution to efficient, durable, and sustainable drainage systems is significant, with a basis in both historical data and future-forward thinking. Whether through documented expertise or the rigorous trust placed in its performance, steel grating remains a cornerstone of effective drainage solutions.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

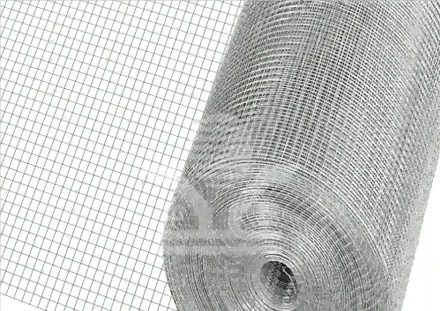

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP