The Importance of Steel Grating for Drainage Systems

Steel grating plays a critical role in modern drainage systems, providing both functionality and durability. As urban areas continue to expand, the need for effective drainage solutions becomes increasingly important. Steel grating serves as an integral component in managing stormwater, preventing flooding, and ensuring the longevity of our infrastructure.

Understanding Steel Grating

Steel grating is a type of material made by welding together a series of parallel bars, forming a grid-like structure. This design allows water to flow through while supporting heavy loads and providing a strong platform. Commonly used in various applications, including walkways, platforms, and drainage systems, steel grating is constructed from high-quality steel, which can be galvanized or coated to resist corrosion and wear.

Advantages of Steel Grating in Drainage Systems

1. Durability and Strength Steel grating is engineered to withstand heavy traffic and extreme environmental conditions. This durability makes it ideal for drainage applications in urban settings, where vehicular traffic can cause substantial wear and tear on traditional materials.

2. Enhanced Water Flow The open design of steel grating allows for efficient water runoff, reducing the risk of blockages and enabling quick drainage during heavy rain. This feature is crucial in preventing flooding and water accumulation on streets and pavements.

3. Safety Features Steel grating is designed with slip-resistant surfaces, which enhance safety in public spaces. In areas prone to wet conditions, this reduction in slip hazards is vital for pedestrian safety, making steel grating an excellent choice for drainage covers in walkways and other high-traffic areas.

steel grating for drainage

4. Low Maintenance Unlike other drainage materials that may require regular repairs or replacements, steel grating's robust construction means it needs minimal maintenance. With proper installation and protective coatings, steel grating can last for decades, significantly reducing lifecycle costs.

5. Versatility Steel grating can be customized to fit various drainage needs. It can be manufactured in different sizes, with varying bar spacing and thicknesses to accommodate specific flow rates and load requirements. This versatility makes it suitable for a wide range of applications, from residential drainage systems to large industrial sites.

Environmental Considerations

Using steel grating in drainage systems aligns with sustainable engineering practices. The material is recyclable, which minimizes environmental impact after its life cycle. Furthermore, effective drainage management reduces surface runoff, which can carry pollutants into water bodies. By facilitating better water management, steel grating contributes to healthier urban ecosystems.

Installation and Maintenance

Proper installation of steel grating is crucial to its effectiveness. It should be securely fastened and aligned with the drainage system to ensure optimal performance. Routine inspections are recommended to check for any signs of wear or debris accumulation, although the maintenance needs are generally low compared to other materials.

Conclusion

In conclusion, steel grating emerges as a superior choice for modern drainage systems. Its durability, efficiency, and safety features make it an ideal solution for managing water runoff in urban infrastructure. As cities grapple with the challenges of increased rainfall and flooding, the demand for reliable drainage solutions like steel grating is more important than ever. By investing in high-quality steel grating for drainage applications, municipalities can enhance public safety, protect infrastructure, and contribute to a sustainable urban environment.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

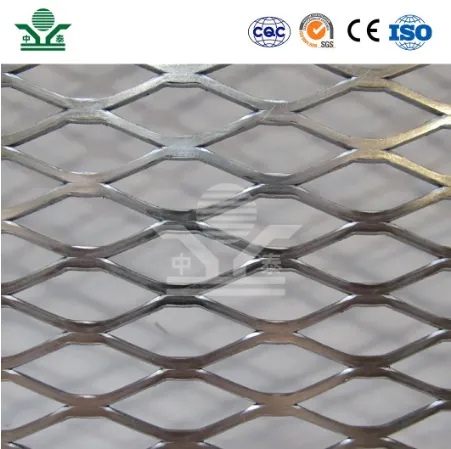

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.