Understanding Steel Grating An Essential Component in Modern Infrastructure

Steel grating is an indispensable component widely used in various industrial and commercial applications. It consists of a series of bearing bars, typically made from carbon steel or stainless steel, which are welded together to form a grid-like structure. This design allows for superior strength, load-bearing capabilities, and slip resistance, making steel grating a popular choice in environments where safety and durability are paramount.

One of the most significant advantages of steel grating is its ability to provide a stable walking surface while allowing for the passage of light, air, and liquids. This feature is particularly beneficial in industrial settings, where it is essential to maintain proper drainage and ventilation. Because of its open design, steel grating is often utilized in walkways, platforms, and stairways, providing both safety and operational efficiency.

The versatility of steel grating extends to a range of industries, including manufacturing, construction, waste management, and aerospace. In manufacturing plants, for instance, steel grating can be found in machinery platforms, machine guards, and even as part of the flooring to facilitate employee movement and reduce slip hazards. In construction, it is used in the fabrication of stair treads, safety barriers, and even as the framework for lightweight structures.

Moreover, steel grating can be treated with various coatings and finishes to enhance its properties and extend its life expectancy. For instance, hot-dip galvanizing is a common method employed to protect steel from rust and corrosion. This process involves immersing the grating in molten zinc, providing a durable layer that withstands harsh environmental conditions. Additionally, powder coating is another option that adds aesthetic value while providing an extra layer of protection.

Steel grating also comes in various types and configurations, which allows it to meet specific load and span requirements. The most common types are welded, pressure-locked, and riveted grating. Each type has its unique installation method and load-bearing capacities, enabling engineers and designers to choose the most suitable option for their projects. For heavy-duty applications, the bearing bars may be thicker and spaced closer together to accommodate higher loads.

steel grating

Environmental considerations are increasingly influencing the choice of materials in construction and infrastructure. Steel, being a recyclable material, offers a sustainable option in an era where reducing waste and conserving resources are imperative. Steel grating can be repurposed at the end of its life cycle, thereby contributing to a circular economy and reducing the environmental impact associated with new material production.

When considering the installation of steel grating, several factors should be taken into account. These include the specific application, load requirements, and local safety regulations. Proper installation is crucial for maximizing safety and functionality. It is essential to ensure that the grating is firmly secured and capable of handling expected foot traffic, machinery, or vehicular loads.

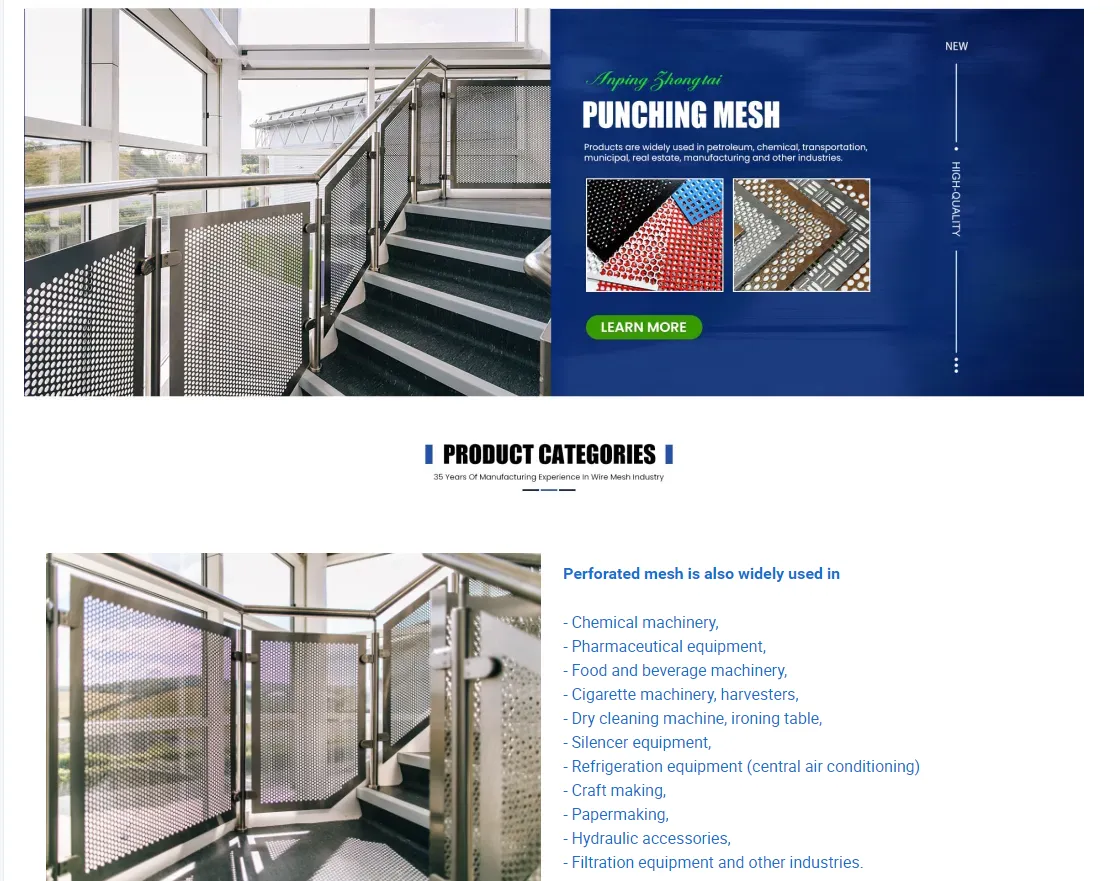

In addition to industrial and commercial uses, steel grating has found its way into architectural designs, adding both function and visual interest to buildings. It can be used as facades, shading devices, or decorative elements, creating a modern and industrial aesthetic while maintaining practical benefits such as ventilation and natural light.

The future of steel grating looks promising, with advancements in technology leading to the development of lighter, stronger, and more versatile products. Innovations in manufacturing processes and materials will continue to enhance the performance and applications of steel grating, making it an even more attractive option for engineers and designers.

In conclusion, steel grating is a vital component of modern infrastructure due to its strength, versatility, and functional benefits. Its applications span a multitude of industries, enhancing safety and efficiency while contributing to sustainability goals. As technology continues to advance, the role of steel grating will likely expand, cementing its position as a cornerstone of industrial and architectural design. Understanding its properties, types, and applications is essential for anyone involved in design, construction, or maintenance within various sectors.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.