Feb . 12, 2025 15:27

Back to list

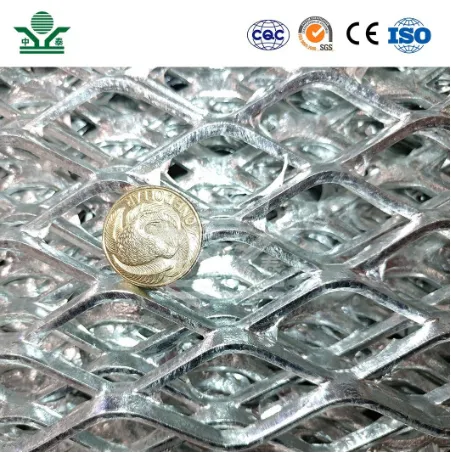

Aluminum Plate Material Expanded Metal Sheet

Choosing the right standard perforated sheet sizes for your project can significantly influence the efficiency and cost-effectiveness of your application. With a multitude of options available, understanding the nuances of perforated sheet sizes and their applications requires both expertise and experience from professionals in the field. In this article, we delve into critical factors that will aid in selecting the optimal perforated sheet size, address common industry misconceptions, and provide authoritative insights to ensure you make informed decisions.

An authoritative resource in the industry, The Industrial Perforators Association, emphasizes the importance of identifying applications where certain sizes excel. For example, a 16-gauge sheet with 3/8 holes at 1 staggered centers might be ideal for ventilation in HVAC systems, as it strikes a balance between airflow and structural integrity. In contrast, automotive panels may benefit more from a finer gauge with smaller openings, providing a lighter yet sturdy construction. Trustworthiness in selecting perforated sheet sizes comes from engaging with suppliers and manufacturers who possess a deep understanding of material science and offer comprehensive technical support. Many reputable companies provide data sheets and customer service teams that discuss project specifics and offer tailored recommendations based on empirical data and past project outcomes. Moreover, building a portfolio of case studies and testimonials from past clients helps establish credibility. These real-world experiences not only provide tangible evidence of performance but also assure prospective clients that they are choosing a trusted provider. In conclusion, while standard perforated sheet sizes are readily available and offer a feasible solution for many projects, deploying them effectively requires a blend of industry expertise and a clear understanding of the application’s demands. Investing time in consulting with seasoned experts and utilizing authoritative resources will deliver better results, ultimately enhancing the functionality, aesthetics, and cost efficiency of your project. Embrace the reliability of standard sizes, but remain open to customization where it adds value—thus ensuring the optimal selection for every unique application.

An authoritative resource in the industry, The Industrial Perforators Association, emphasizes the importance of identifying applications where certain sizes excel. For example, a 16-gauge sheet with 3/8 holes at 1 staggered centers might be ideal for ventilation in HVAC systems, as it strikes a balance between airflow and structural integrity. In contrast, automotive panels may benefit more from a finer gauge with smaller openings, providing a lighter yet sturdy construction. Trustworthiness in selecting perforated sheet sizes comes from engaging with suppliers and manufacturers who possess a deep understanding of material science and offer comprehensive technical support. Many reputable companies provide data sheets and customer service teams that discuss project specifics and offer tailored recommendations based on empirical data and past project outcomes. Moreover, building a portfolio of case studies and testimonials from past clients helps establish credibility. These real-world experiences not only provide tangible evidence of performance but also assure prospective clients that they are choosing a trusted provider. In conclusion, while standard perforated sheet sizes are readily available and offer a feasible solution for many projects, deploying them effectively requires a blend of industry expertise and a clear understanding of the application’s demands. Investing time in consulting with seasoned experts and utilizing authoritative resources will deliver better results, ultimately enhancing the functionality, aesthetics, and cost efficiency of your project. Embrace the reliability of standard sizes, but remain open to customization where it adds value—thus ensuring the optimal selection for every unique application.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP