Jan . 28, 2025 05:28

Back to list

Round hole perforated mesh

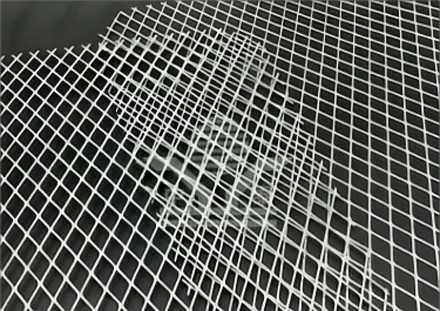

Stainless wire grates have become an essential component in numerous industries, from the culinary world to engineering and manufacturing. Their versatility, durability, and performance make them a preferred choice for various applications. The allure of stainless wire grates lies not only in their robustness but also in their adaptability to meet diverse needs across different sectors.

All of the aforementioned applications underscore the importance of expertise when selecting the right type of stainless wire grate. Factors such as wire diameter, weave pattern, and alloy composition must be carefully considered to meet the specific demands of the application. Professionals in the field emphasize the critical nature of understanding these variables as they directly affect the performance and longevity of the grates in their respective environments. Authoritative sources in the stainless steel industry continually stress the importance of choosing grates manufactured by reputable companies. The market is inundated with varying qualities of stainless steel, making it imperative to source from manufacturers with a proven track record of quality and compliance with industry standards. Trust in the product is built through certifications, such as ISO standards, which assure the end-users of the material’s integrity. For consumers new to stainless wire grates, understanding the maintenance requirements is crucial to maximizing their lifespan. Regular cleaning with mild detergents can preserve the brightness and cleanliness of the grates, while also preventing any potential buildup that could lead to long-term degradation. Furthermore, routine inspections for any signs of wear or damage ensure that the grates function as intended throughout their service life. In conclusion, the enduring popularity of stainless wire grates across various domains can be attributed to their exceptional properties and reliable performance. Their applications span from culinary excellence to industrial necessity, with a growing influence in design and architecture. Ongoing innovations in manufacturing technologies continue to enhance the capabilities of stainless wire grates, promising even greater utility in the future. As industries evolve, the demand for high-quality, efficient, and durable materials like stainless wire grates will undoubtedly persist, affirming their status as indispensable tools in both current and future applications.

All of the aforementioned applications underscore the importance of expertise when selecting the right type of stainless wire grate. Factors such as wire diameter, weave pattern, and alloy composition must be carefully considered to meet the specific demands of the application. Professionals in the field emphasize the critical nature of understanding these variables as they directly affect the performance and longevity of the grates in their respective environments. Authoritative sources in the stainless steel industry continually stress the importance of choosing grates manufactured by reputable companies. The market is inundated with varying qualities of stainless steel, making it imperative to source from manufacturers with a proven track record of quality and compliance with industry standards. Trust in the product is built through certifications, such as ISO standards, which assure the end-users of the material’s integrity. For consumers new to stainless wire grates, understanding the maintenance requirements is crucial to maximizing their lifespan. Regular cleaning with mild detergents can preserve the brightness and cleanliness of the grates, while also preventing any potential buildup that could lead to long-term degradation. Furthermore, routine inspections for any signs of wear or damage ensure that the grates function as intended throughout their service life. In conclusion, the enduring popularity of stainless wire grates across various domains can be attributed to their exceptional properties and reliable performance. Their applications span from culinary excellence to industrial necessity, with a growing influence in design and architecture. Ongoing innovations in manufacturing technologies continue to enhance the capabilities of stainless wire grates, promising even greater utility in the future. As industries evolve, the demand for high-quality, efficient, and durable materials like stainless wire grates will undoubtedly persist, affirming their status as indispensable tools in both current and future applications.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP