Feb . 05, 2025 05:38

Back to list

Zhongtai Bending Perforated Metal China Factory Metric Perforated Sheet Metal

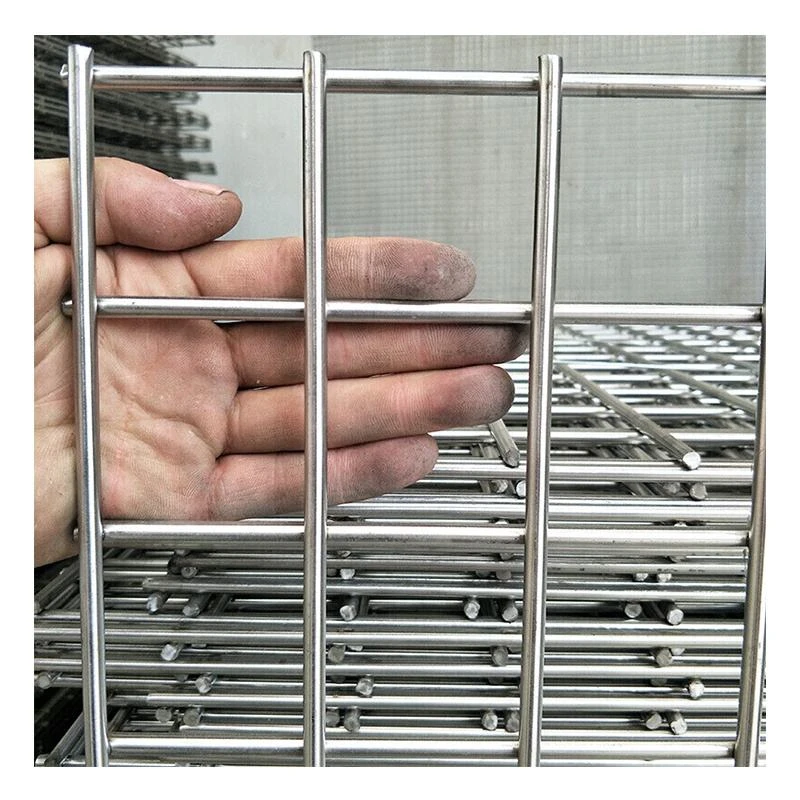

Stainless steel punched metal sheets have revolutionized various industries, offering a fusion of versatility, durability, and aesthetic appeal. With years of experience in the field of metal fabrication, I can confidently assert that these perforated sheets are not just a material of choice but a game-changer in product design and architecture. Their unique characteristics set them apart, enabling them to cater to a wide array of applications, from industrial to decorative purposes.

Trust in stainless steel punched metal sheets is further solidified by their extensive track record in high-stakes applications. Industries such as aerospace, automotive, and petrochemical sectors continually rely on these materials for critical components, owing to their unmatched durability and adaptability. Furthermore, sustainability is a hallmark of stainless steel, with its recyclability contributing to environmentally conscious practices—a factor increasingly prioritized by industry leaders and consumers alike. The aesthetic capabilities of stainless steel punched metal sheets cannot be overstated. Their ability to seamlessly integrate into both modern and traditional design schemes makes them a favorite among architects and designers. Whether employed as decorative facades, interior partitions, or artistic features, these sheets elevate visual appeal while maintaining functional integrity. The interplay of light and shadow through perforations creates dynamic spaces, enhancing ambiance and contributing to a building's identity. In conclusion, stainless steel punched metal sheets embody the intersection of experience, expertise, authoritativeness, and trustworthiness. They stand as a pivotal material that continues to redefine possibilities across various domains. For those seeking innovative and reliable solutions, these sheets offer an unrivaled combination of practicality and aesthetic allure. As the landscape of material science evolves, their role is poised to expand, continually shaping the future of design and manufacturing.

Trust in stainless steel punched metal sheets is further solidified by their extensive track record in high-stakes applications. Industries such as aerospace, automotive, and petrochemical sectors continually rely on these materials for critical components, owing to their unmatched durability and adaptability. Furthermore, sustainability is a hallmark of stainless steel, with its recyclability contributing to environmentally conscious practices—a factor increasingly prioritized by industry leaders and consumers alike. The aesthetic capabilities of stainless steel punched metal sheets cannot be overstated. Their ability to seamlessly integrate into both modern and traditional design schemes makes them a favorite among architects and designers. Whether employed as decorative facades, interior partitions, or artistic features, these sheets elevate visual appeal while maintaining functional integrity. The interplay of light and shadow through perforations creates dynamic spaces, enhancing ambiance and contributing to a building's identity. In conclusion, stainless steel punched metal sheets embody the intersection of experience, expertise, authoritativeness, and trustworthiness. They stand as a pivotal material that continues to redefine possibilities across various domains. For those seeking innovative and reliable solutions, these sheets offer an unrivaled combination of practicality and aesthetic allure. As the landscape of material science evolves, their role is poised to expand, continually shaping the future of design and manufacturing.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP