Feb . 06, 2025 00:48

Back to list

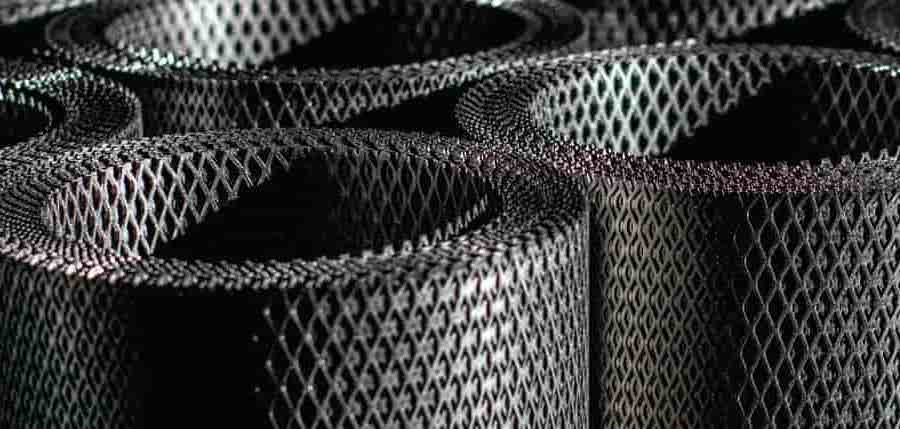

stainless steel perforated sheet

Stainless steel perforated sheets have become an increasingly sought-after product in various industries due to their versatile applications and durability. These sheets offer a compelling combination of strength, resistance to corrosion, and aesthetic appeal, making them an ideal solution for a range of practical and creative applications.

Trustworthiness is another cornerstone of why stainless steel perforated sheets are a preferred choice. Consumers can rely on the long lifespan and minimal maintenance requirements of these sheets, which translates to cost savings over time. Their inherent resistance to environmental wear and tear ensures that structures or products utilizing these sheets remain safe and operational far beyond initial installation. Suppliers of these robust materials often provide warranties or certifications to further instill confidence in their use, reflecting the high standards of production and quality assurance maintained by reputable manufacturers. Furthermore, industries have continued to innovate in the application of these sheets, such as in environmental protection projects. Engineers incorporate them into systems designed to reduce noise pollution through sound barriers, or to enhance water filtration systems, proving that their utility extends beyond mere functional applications. By capitalizing on the aesthetic possibilities, designers have also integrated these into artistic installations and intricate interior designs, demonstrating their versatility and appeal across disciplines. With each application, stainless steel perforated sheets demonstrate their value not only through practical benefits but also through the latent possibilities of innovative thinking they inspire. Whether it's optimizing efficiency in industrial settings or revolutionizing architectural design, these sheets have become indispensable across numerous applications. By consistently delivering high performance and reliability, they stand as a testament to cutting-edge engineering and quality craftsmanship. In conclusion, the strategic use of stainless steel perforated sheets illustrates a marriage of function and creativity, reinforced by industry expertise and an unwavering trust in the material's capabilities. As technology and applications continue to evolve, these sheets will undoubtedly play an even more significant role in forging a future of advanced industrial and aesthetic solutions.

Trustworthiness is another cornerstone of why stainless steel perforated sheets are a preferred choice. Consumers can rely on the long lifespan and minimal maintenance requirements of these sheets, which translates to cost savings over time. Their inherent resistance to environmental wear and tear ensures that structures or products utilizing these sheets remain safe and operational far beyond initial installation. Suppliers of these robust materials often provide warranties or certifications to further instill confidence in their use, reflecting the high standards of production and quality assurance maintained by reputable manufacturers. Furthermore, industries have continued to innovate in the application of these sheets, such as in environmental protection projects. Engineers incorporate them into systems designed to reduce noise pollution through sound barriers, or to enhance water filtration systems, proving that their utility extends beyond mere functional applications. By capitalizing on the aesthetic possibilities, designers have also integrated these into artistic installations and intricate interior designs, demonstrating their versatility and appeal across disciplines. With each application, stainless steel perforated sheets demonstrate their value not only through practical benefits but also through the latent possibilities of innovative thinking they inspire. Whether it's optimizing efficiency in industrial settings or revolutionizing architectural design, these sheets have become indispensable across numerous applications. By consistently delivering high performance and reliability, they stand as a testament to cutting-edge engineering and quality craftsmanship. In conclusion, the strategic use of stainless steel perforated sheets illustrates a marriage of function and creativity, reinforced by industry expertise and an unwavering trust in the material's capabilities. As technology and applications continue to evolve, these sheets will undoubtedly play an even more significant role in forging a future of advanced industrial and aesthetic solutions.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP