Stainless Steel Perforated Mesh Sheets Versatility and Applications

Stainless steel perforated mesh sheets have become increasingly popular in various industries due to their unique properties and versatility. These sheets are made from high-quality stainless steel that has been perforated with a pattern of holes, allowing for a range of functional applications, from aesthetics to filtration and structural support. This article explores the features, benefits, and applications of stainless steel perforated mesh sheets, highlighting their significance in various sectors.

One of the primary advantages of stainless steel perforated mesh sheets is their durability. Made from stainless steel, these sheets are resistant to corrosion, rust, and tarnishing, ensuring a long lifespan even in harsh environments. This makes them ideal for outdoor applications, where exposure to the elements can be detrimental to other materials. Their robust nature allows them to maintain structural integrity and appearance over time, making them a cost-effective choice for businesses and homeowners alike.

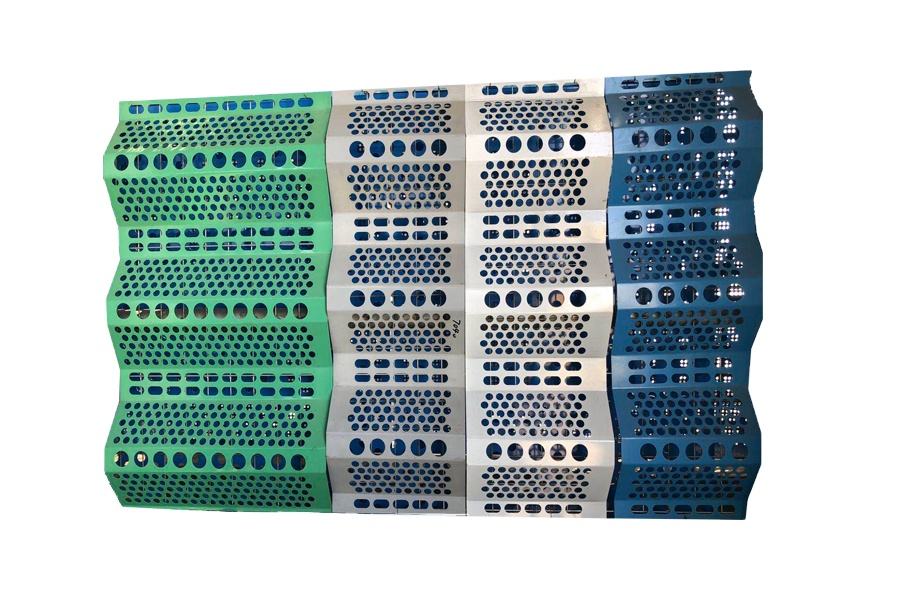

Another notable feature of stainless steel perforated mesh sheets is their aesthetic appeal. Available in various hole sizes, shapes, and patterns, these sheets can be used to create visually striking designs for architecture and interior decor. They are often employed in facades, screens, and railings, adding a modern touch to buildings while allowing light and air to flow through. The combination of functionality and style makes stainless steel perforated mesh a preferred choice for architects and designers seeking innovative solutions.

In addition to aesthetics, stainless steel perforated mesh sheets also play a crucial role in industrial applications. They are widely used in filtering and screening processes across different industries, including food and beverage, pharmaceuticals, and chemicals. The perforations in the mesh allow for efficient separation and filtration of particles while providing adequate airflow. This is essential in maintaining product quality and ensuring compliance with industry standards.

stainless steel perforated mesh sheet

The strength and rigidity of stainless steel perforated mesh sheets make them suitable for structural applications as well. They can be used as reinforcement in various construction projects, providing added support to walls, ceilings, and floors. Their lightweight nature, combined with their structural integrity, allows for easier handling and installation, making them a practical choice for contractors and builders.

Moreover, the eco-friendliness of stainless steel perforated mesh sheets cannot be overlooked. Stainless steel is a recyclable material, which means that products made from this material contribute to sustainability efforts. Using stainless steel mesh not only reduces environmental impact but also aligns with the growing demand for sustainable building materials in construction.

The versatility of stainless steel perforated mesh sheets extends to their use in various applications beyond construction and filtration. For example, they are commonly used in the automotive industry for exhaust systems, as they allow gases to escape while preventing the entry of larger debris. Additionally, they find applications in the manufacturing of furniture, such as metal screens, tables, and chairs, where both functionality and style are essential.

In conclusion, stainless steel perforated mesh sheets are a remarkable material that offers a blend of durability, aesthetic appeal, and versatility. Their resistance to corrosion, combined with their wide range of applications across several industries, makes them an invaluable asset in modern manufacturing, construction, and design. As industries continue to seek innovative solutions that balance functionality with sustainability, stainless steel perforated mesh sheets will undoubtedly maintain their relevance and popularity in the market. Whether for structural, aesthetic, or functional purposes, these sheets are sure to remain a staple in both industrial and artistic applications for years to come.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.