Understanding Stainless Steel Perforated Sheets Versatility and Applications

Stainless steel perforated sheets are versatile materials widely used across various industries due to their unique combination of strength, durability, and aesthetic appeal. These sheets are made from stainless steel, a corrosion-resistant alloy that includes at least 10.5% chromium. This composition provides excellent resistance to rust and oxidation, making stainless steel ideal for harsh environments.

The perforation process involves creating a pattern of holes in sheets of stainless steel. These holes can vary in size, shape, and spacing depending on the intended application. The perforation not only reduces the weight of the material but also enhances its functionality by allowing air, light, and sound to pass through. This feature is particularly beneficial in construction, acoustics, and filtration applications.

One of the most common uses of stainless steel perforated sheets is in architectural applications. Designers and architects often employ these sheets for facades, screens, and decorative elements. The ability to customize hole patterns allows for creative designs that can express a unique aesthetic while still providing the benefits of ventilation and light diffusion. For instance, a stainless steel perforated façade can significantly reduce solar heat gain in buildings while maintaining an open and airy feel.

In industrial settings, stainless steel perforated sheets play a critical role in filtration systems. Their ability to maintain structural integrity in corrosive environments makes them suitable for applications in chemical processing, food and beverage, pharmaceuticals, and wastewater treatment. The precise hole sizes can be engineered to filter out specific particles while allowing liquids and gases to flow freely, thus optimizing operational efficiency.

stainless steel perforated

The use of stainless steel perforated sheets also extends to the automotive industry, where they are often used in mufflers and exhaust systems to reduce sound and improve airflow

. Additionally, the incorporation of these sheets in marine applications, such as boat hulls and decks, helps mitigate the effects of saltwater corrosion, prolonging the lifespan of vessels.Another notable application of stainless steel perforated sheets is in the design of furniture and fixtures. From shelving units to lighting fixtures, the perforated design adds both functionality and style, allowing for ventilation and illumination while providing a modern aesthetic.

Furthermore, the ease of maintenance associated with stainless steel makes these perforated sheets a preferred choice for many environments. Simple cleaning techniques are sufficient to maintain their appearance and performance, contributing to lower long-term maintenance costs.

In conclusion, stainless steel perforated sheets serve a multitude of purposes across various industries thanks to their robustness, aesthetic versatility, and functional benefits. Whether in architecture or filtration systems, these materials effectively combine utility with design, making them an invaluable asset in modern manufacturing and construction. As technology advances, we can expect to see even more innovative applications for stainless steel perforated sheets, solidifying their position as essential components in a variety of sectors.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

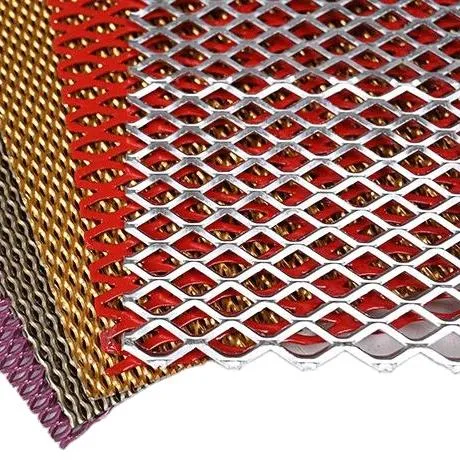

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.