Jan . 29, 2025 00:48

Back to list

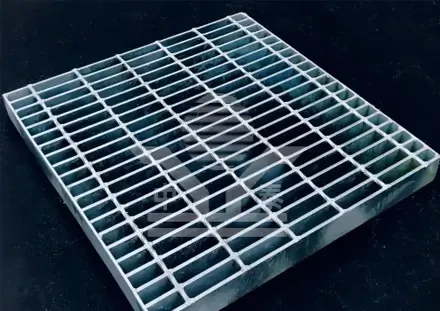

stainless steel drain grating

In the world of construction and interior design, the stainless steel drain grating stands out as a pivotal component, often overlooked but fundamentally essential for a variety of applications. With decades of experience in the field of material engineering and product design, I can assure you that selecting the right stainless steel drain grating can dramatically impact not only the functionality but also the safety and aesthetics of your project.

Furthermore, from a design perspective, the aesthetic characteristics of stainless steel enhance the overall environment. With a sleek, modern appearance, these gratings integrate well into minimalist and contemporary design themes. Polished or brushed finishes can complement the décor while providing an unobtrusive yet functional element. The reflective quality of stainless steel can also add a sense of space and light to darker areas, improving the overall ambiance. When it comes to authoritativeness in the industry, manufacturers often follow stringent quality standards, ensuring each product adheres to both local and international building codes. Certifications such as ISO 9001 for quality management and compliance with standards like ASME or ASTM demonstrate a commitment to producing reliable components. Verification by independent third-party organizations further reinforces trust. Trustworthiness is at the core of any enduring product choice. Stainless steel, known for its longevity and minimal maintenance, offers peace of mind for property owners and managers. Regular upkeep typically involves straightforward cleaning with non-abrasive materials and, if necessary, periodic inspection for damage caused by unusual stressors. The long lifespan reduces the need for frequent replacements, thus lowering the total cost of ownership. To summarize, stainless steel drain gratings combine unparalleled utility with a contemporary aesthetic, backed by robust engineering principles and industry standards. For anyone involved in construction, urban planning, or interior design, the choice of stainless steel gratings offers a harmonious blend of form and function. Prioritizing these elements can result in enhanced operational efficiency, elevated safety, and a sophisticated finish to any environment. With careful selection and expertise, these components provide an essential foundation for effective design and infrastructure solutions.

Furthermore, from a design perspective, the aesthetic characteristics of stainless steel enhance the overall environment. With a sleek, modern appearance, these gratings integrate well into minimalist and contemporary design themes. Polished or brushed finishes can complement the décor while providing an unobtrusive yet functional element. The reflective quality of stainless steel can also add a sense of space and light to darker areas, improving the overall ambiance. When it comes to authoritativeness in the industry, manufacturers often follow stringent quality standards, ensuring each product adheres to both local and international building codes. Certifications such as ISO 9001 for quality management and compliance with standards like ASME or ASTM demonstrate a commitment to producing reliable components. Verification by independent third-party organizations further reinforces trust. Trustworthiness is at the core of any enduring product choice. Stainless steel, known for its longevity and minimal maintenance, offers peace of mind for property owners and managers. Regular upkeep typically involves straightforward cleaning with non-abrasive materials and, if necessary, periodic inspection for damage caused by unusual stressors. The long lifespan reduces the need for frequent replacements, thus lowering the total cost of ownership. To summarize, stainless steel drain gratings combine unparalleled utility with a contemporary aesthetic, backed by robust engineering principles and industry standards. For anyone involved in construction, urban planning, or interior design, the choice of stainless steel gratings offers a harmonious blend of form and function. Prioritizing these elements can result in enhanced operational efficiency, elevated safety, and a sophisticated finish to any environment. With careful selection and expertise, these components provide an essential foundation for effective design and infrastructure solutions.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP