Jan . 25, 2025 23:49

Back to list

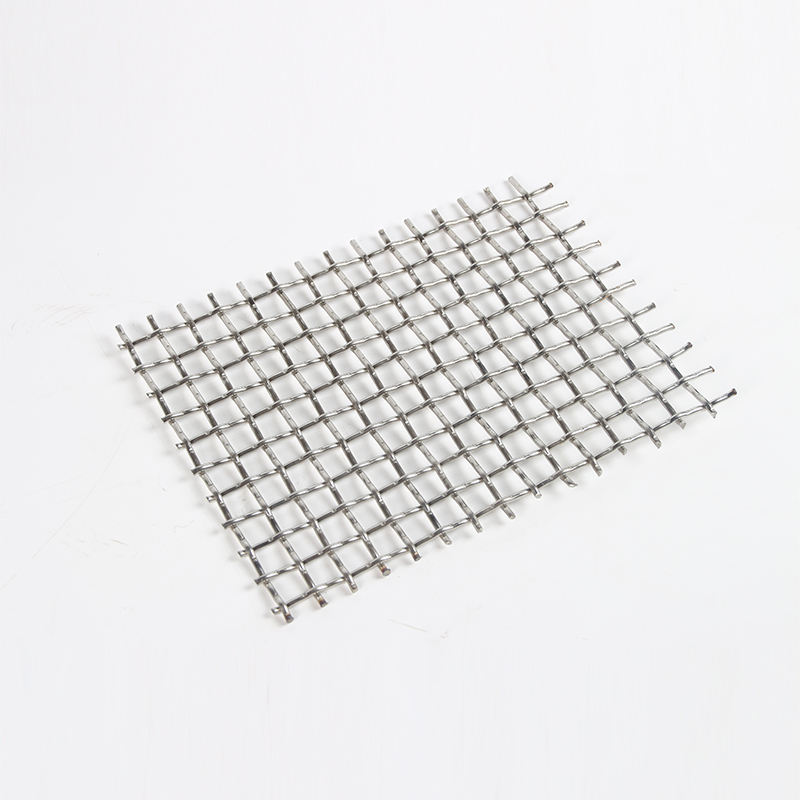

heavy duty steel bar grating

Stainless steel bar grating stands as a paramount solution for those seeking durability combined with versatility in their design and construction projects. As an essential component in numerous industrial applications, it’s vital to understand why this seemingly simple product earns such high esteem in sectors ranging from architecture to manufacturing.

Manufacturers have also embraced technology, enhancing the fabrication process of stainless steel bar grating. Advanced welding techniques and precise machining ensure maximum consistency and strength. Optional surface treatments, such as galvanization, provide added resilience to the harshest conditions, further extending the grating’s lifespan. In architectural applications, the aesthetic appeal of stainless steel bar grating is undeniable. Architects frequently use it not only for its functionality but also for its modern and sleek appearance. It can add an industrial touch to contemporary designs, serving both as a functional element and a design feature. Open grating allows for the flow of light and air, which can contribute to energy savings and enhance ventilation in building interiors. The versatility of stainless steel bar grating is further showcased in its adaptability to various shapes and sizes, accommodating specific site layouts or design visions. This adaptability makes it a preferred choice for creative constructions, including sculptures, bridges, and art installations, where structural soundness must harmonize with visual allure. In conclusion, stainless steel bar grating represents more than a mere building material. It embodies a synthesis of strength, reliability, and aesthetic potential that few other materials can offer. For industry experts and newcomers alike, investing in stainless steel bar grating is a commitment to quality, innovation, and sustainability. As this product continues to evolve with technological advances, it will undoubtedly remain a pivotal component in both industrial and architectural landscapes.

Manufacturers have also embraced technology, enhancing the fabrication process of stainless steel bar grating. Advanced welding techniques and precise machining ensure maximum consistency and strength. Optional surface treatments, such as galvanization, provide added resilience to the harshest conditions, further extending the grating’s lifespan. In architectural applications, the aesthetic appeal of stainless steel bar grating is undeniable. Architects frequently use it not only for its functionality but also for its modern and sleek appearance. It can add an industrial touch to contemporary designs, serving both as a functional element and a design feature. Open grating allows for the flow of light and air, which can contribute to energy savings and enhance ventilation in building interiors. The versatility of stainless steel bar grating is further showcased in its adaptability to various shapes and sizes, accommodating specific site layouts or design visions. This adaptability makes it a preferred choice for creative constructions, including sculptures, bridges, and art installations, where structural soundness must harmonize with visual allure. In conclusion, stainless steel bar grating represents more than a mere building material. It embodies a synthesis of strength, reliability, and aesthetic potential that few other materials can offer. For industry experts and newcomers alike, investing in stainless steel bar grating is a commitment to quality, innovation, and sustainability. As this product continues to evolve with technological advances, it will undoubtedly remain a pivotal component in both industrial and architectural landscapes.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP