Feb . 06, 2025 02:31

Back to list

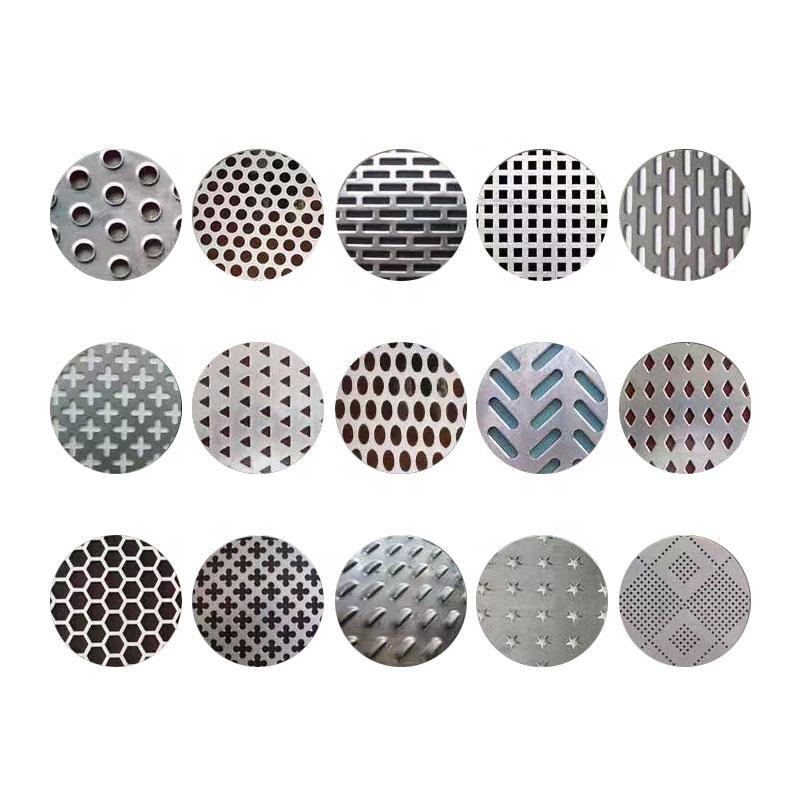

stainless steel 304 perforated sheet

Stainless steel 304 perforated sheets stand as a testament to modern engineering and material science, marking a perfect blend of strength, aesthetics, and versatile application. Being one of the most common grades of stainless steel, the 304 variant is renowned for its excellent forming and welding characteristics. This makes it an optimal choice for a myriad of applications that require enhanced durability and resistance.

Trustworthiness in the quality and performance of stainless steel 304 perforated sheets can largely be attributed to rigorous quality control standards adhered to during production. Certifications such as ISO 9001 ensure that the manufacturing processes meet the highest international standards, guaranteeing product consistency and reliability. Buyers should always verify these certifications to secure the best possible outcomes from their purchases. The environmental aspect adds another layer of credibility to the use of these sheets. As a recyclable material, stainless steel significantly reduces ecological impact, aligning with the global push towards more sustainable industrial practices. The lifecycle of stainless steel 304 perforated sheets showcases reduced waste footprints and energy efficiency, supporting industries in achieving sustainable development goals. Finally, considering the total cost of ownership, stainless steel 304 perforated sheets offer an economic advantage. While the initial investment might be higher compared to other materials, the long-term durability, reduced maintenance needs, and extended lifespan provide significant savings over time. This cost-benefit ratio highlights the strategic advantage of selecting stainless steel 304 perforated sheets for both small and large scale projects. In conclusion, stainless steel 304 perforated sheets offer a unique combination of features that are highly valued across different sectors. Their unparalleled durability, aesthetic flexibility, and sustainable benefits underscore their status as a preferred material for architects, engineers, and manufacturers alike. By leveraging their full potential, stakeholders not only enhance the efficiency and appeal of their projects but also contribute positively to environmental conservation efforts.

Trustworthiness in the quality and performance of stainless steel 304 perforated sheets can largely be attributed to rigorous quality control standards adhered to during production. Certifications such as ISO 9001 ensure that the manufacturing processes meet the highest international standards, guaranteeing product consistency and reliability. Buyers should always verify these certifications to secure the best possible outcomes from their purchases. The environmental aspect adds another layer of credibility to the use of these sheets. As a recyclable material, stainless steel significantly reduces ecological impact, aligning with the global push towards more sustainable industrial practices. The lifecycle of stainless steel 304 perforated sheets showcases reduced waste footprints and energy efficiency, supporting industries in achieving sustainable development goals. Finally, considering the total cost of ownership, stainless steel 304 perforated sheets offer an economic advantage. While the initial investment might be higher compared to other materials, the long-term durability, reduced maintenance needs, and extended lifespan provide significant savings over time. This cost-benefit ratio highlights the strategic advantage of selecting stainless steel 304 perforated sheets for both small and large scale projects. In conclusion, stainless steel 304 perforated sheets offer a unique combination of features that are highly valued across different sectors. Their unparalleled durability, aesthetic flexibility, and sustainable benefits underscore their status as a preferred material for architects, engineers, and manufacturers alike. By leveraging their full potential, stakeholders not only enhance the efficiency and appeal of their projects but also contribute positively to environmental conservation efforts.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP