Jan . 25, 2025 21:30

Back to list

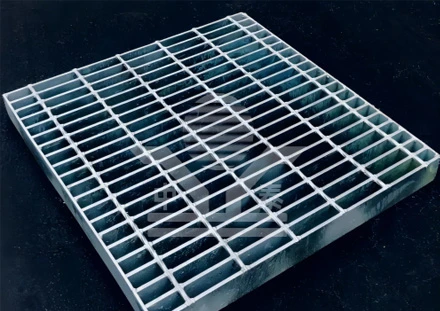

ss grating price

In the dynamic world of construction and industrial applications, the need for durable, cost-effective, and reliable solutions is ever-present. Among the myriad of options available, SS grating stands out as a product that excels in addressing these demands. As steel grating continues to gain popularity, it is crucial to delve into its pricing components, especially if you are considering it for your next project. Understanding the factors that influence SS grating prices can empower you to make informed purchasing decisions.

It is also important to consider the market dynamics and external factors affecting raw material costs. Stainless steel prices fluctuate based on factors such as demand in the construction industry, global steel production rates, and economic conditions. Staying informed about these trends can help in identifying the optimum time for procurement, potentially offering substantial cost savings. Transportation and logistical considerations are frequently overlooked but crucial to the final cost of SS grating. Given its weight and size, the logistics of transporting steel grating panels can become a significant cost factor. Opting for suppliers closer to the project site, or those offering competitive shipping rates, can help mitigate these expenses. Finally, the supplier's reputation and after-sales service quality are paramount in influencing the perceived value of SS grating. Reputable manufacturers might charge a premium, reflecting their commitment to quality, adherence to industry standards, and robust after-sales support. Investing in grating from a credible supplier can ensure product longevity, reliability, and, ultimately, cost-effectiveness over the life of the project. In conclusion, while the price of SS grating stems from a combination of material choice, manufacturing technique, customization, finishing, market dynamics, transportation, and supplier credibility, understanding these factors holistically equips you to make strategic purchasing decisions. By carefully balancing project demands with these pricing elements, the adoption of SS grating can prove to be a prudent and advantageous choice for both immediate and long-term purposes.

It is also important to consider the market dynamics and external factors affecting raw material costs. Stainless steel prices fluctuate based on factors such as demand in the construction industry, global steel production rates, and economic conditions. Staying informed about these trends can help in identifying the optimum time for procurement, potentially offering substantial cost savings. Transportation and logistical considerations are frequently overlooked but crucial to the final cost of SS grating. Given its weight and size, the logistics of transporting steel grating panels can become a significant cost factor. Opting for suppliers closer to the project site, or those offering competitive shipping rates, can help mitigate these expenses. Finally, the supplier's reputation and after-sales service quality are paramount in influencing the perceived value of SS grating. Reputable manufacturers might charge a premium, reflecting their commitment to quality, adherence to industry standards, and robust after-sales support. Investing in grating from a credible supplier can ensure product longevity, reliability, and, ultimately, cost-effectiveness over the life of the project. In conclusion, while the price of SS grating stems from a combination of material choice, manufacturing technique, customization, finishing, market dynamics, transportation, and supplier credibility, understanding these factors holistically equips you to make strategic purchasing decisions. By carefully balancing project demands with these pricing elements, the adoption of SS grating can prove to be a prudent and advantageous choice for both immediate and long-term purposes.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP