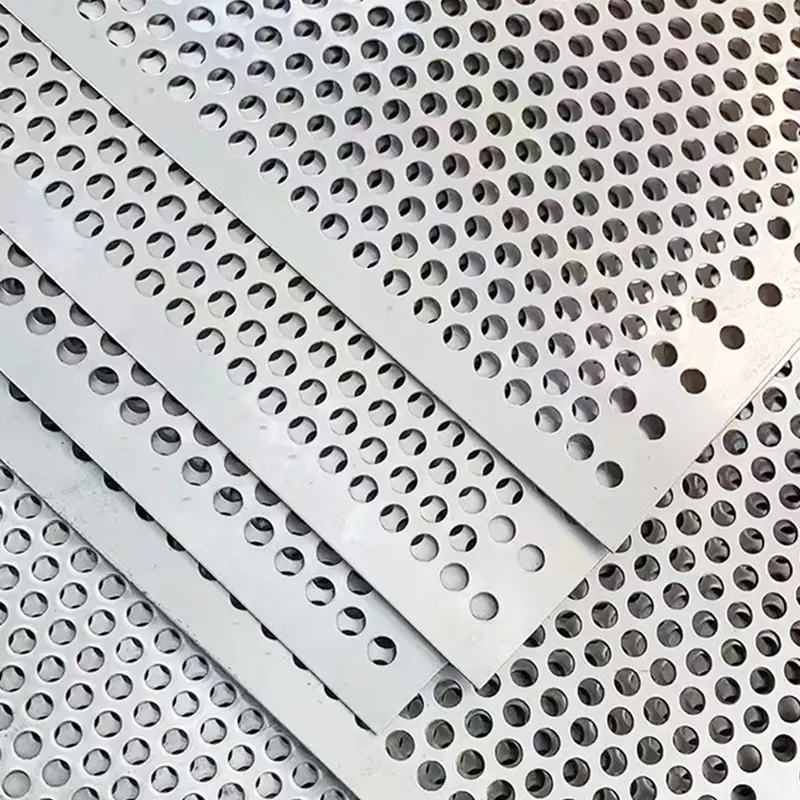

Understanding Square Hole Perforated Sheets Features, Applications, and Benefits

Square hole perforated sheets have become increasingly popular in various industries, owing to their unique structural properties and aesthetic appeal. These sheets, characterized by a grid of square holes punched through a flat sheet of material, offer a combination of functionality and versatility that make them a preferred choice for architects, engineers, and designers alike.

Construction and Design

Square hole perforated sheets are typically made from materials such as stainless steel, aluminum, or galvanized steel. The holes can vary in size and spacing, allowing for customization to meet specific design requirements. The uniformity of square holes not only enhances the sheet’s structural integrity but also contributes to a visually appealing pattern that can elevate the overall aesthetics of a project.

The perforation process, which involves using high-precision machinery, ensures that each hole is cleanly punched without compromising the material’s integrity. This precision allows for better control over airflow, light penetration, and sound diffusion, tailoring each sheet to the demands of its intended use.

Applications

The versatility of square hole perforated sheets permits their use in a multitude of applications across various sectors

1. Architecture and Design They are commonly used for facades, ceiling panels, and decorative wall covers. The open design allows for creative architectural solutions, balancing functionality with visual interest.

2. Industrial Manufacturing In industrial settings, square hole perforated sheets are utilized for sieves and filters, enabling efficient separation processes while maintaining airflow. They are essential in creating dust or noise barriers, thereby enhancing workplace safety and comfort.

3. Furniture and Fixtures Designers often incorporate these sheets into furniture, providing a modern look with practical benefits, such as ventilation in office partitions or aesthetic appeal in shelving units.

square hole perforated sheet

4. Acoustic Applications Due to their sound diffusion properties, square hole perforated sheets are valuable in acoustics engineering. They help in controlling sound reverberation, making them useful in auditoriums, recording studios, and other spaces where sound clarity is paramount.

Benefits

The advantages of using square hole perforated sheets are manifold

- Lightweight and Durable Despite their lightweight structure, these sheets offer exceptional strength, ensuring longevity and ease of handling during installation.

- Customizable Their adaptability allows for endless design possibilities. Whether for industrial applications or artistic installations, tailored solutions can be crafted to meet specific needs.

- Sustainable Options Many manufacturers now offer perforated sheets made from recyclable materials, contributing to environmentally friendly construction practices.

- Ease of Maintenance The open design facilitates easy cleaning and maintenance, ensuring that aesthetic standards are upheld over time without significant effort.

Conclusion

Square hole perforated sheets represent a blend of functionality and style, making them an indispensable component in modern construction and design. Their adaptability across various sectors, combined with their aesthetic allure, positions them as a critical material in both architectural innovation and industrial efficiency. As industries continue to evolve, the demand for customizable and sustainable materials like square hole perforated sheets is likely to grow, paving the way for exciting developments in design and engineering.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.