Feb . 02, 2025 02:19

Back to list

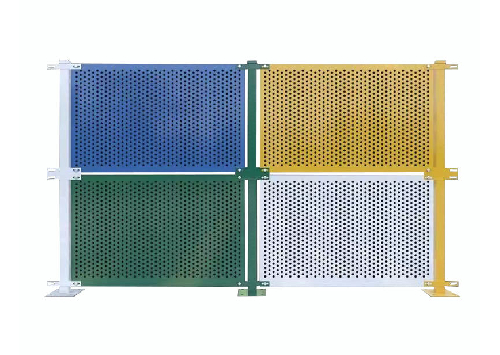

square hole perforated sheet metal

Square hole perforated sheets are versatile materials extensively used across different industries. These sheets, distinguished by their square-shaped holes, provide numerous functional and aesthetic benefits that make them a go-to choice for many applications.

Their installation process is equally streamlined to accommodate both large-scale industrial implementations and smaller personal projects. Typically, these sheets are easy to cut or mold, enabling quick adaptation to specific spatial requirements. This adaptability reduces installation time and cost, making them a financially sound choice for both commercial constructors and hobbyists. A noteworthy aspect of square hole perforated sheets is their sustainability potential. Given the growing emphasis on eco-friendly practices, these sheets often meet LEED requirements, facilitating the construction of sustainable buildings. They can be sourced from recycled materials, and at the end of their life cycle, they can again be recycled, thereby reducing the environmental footprint. Expert testimonials often highlight the balance of aesthetics and functionality that square hole perforated sheets bring to projects. Real-world applications corroborate their reliability and efficacy, as illustrated in numerous case studies from industries spanning from agriculture to aerospace. Experts in the field advocate for their use, underscoring the sheets' durability and versatility. For consumers or professionals considering the integration of square hole perforated sheets, it's vital to partner with reputable suppliers who provide product guarantees and customization services. Ensuring that the products meet quality standards and fit the specific needs of a project is essential for maximizing their benefits. In summary, square hole perforated sheets are more than just a construction material—they represent a confluence of innovation, efficiency, and design adaptability. Their extensive range of applications and robust nature position them as an invaluable asset in contemporary architecture and industry. Whether for enhancing structural beauty, improving functionality, or achieving environmental goals, the uses of these sheets are as diverse as they are essential.

Their installation process is equally streamlined to accommodate both large-scale industrial implementations and smaller personal projects. Typically, these sheets are easy to cut or mold, enabling quick adaptation to specific spatial requirements. This adaptability reduces installation time and cost, making them a financially sound choice for both commercial constructors and hobbyists. A noteworthy aspect of square hole perforated sheets is their sustainability potential. Given the growing emphasis on eco-friendly practices, these sheets often meet LEED requirements, facilitating the construction of sustainable buildings. They can be sourced from recycled materials, and at the end of their life cycle, they can again be recycled, thereby reducing the environmental footprint. Expert testimonials often highlight the balance of aesthetics and functionality that square hole perforated sheets bring to projects. Real-world applications corroborate their reliability and efficacy, as illustrated in numerous case studies from industries spanning from agriculture to aerospace. Experts in the field advocate for their use, underscoring the sheets' durability and versatility. For consumers or professionals considering the integration of square hole perforated sheets, it's vital to partner with reputable suppliers who provide product guarantees and customization services. Ensuring that the products meet quality standards and fit the specific needs of a project is essential for maximizing their benefits. In summary, square hole perforated sheets are more than just a construction material—they represent a confluence of innovation, efficiency, and design adaptability. Their extensive range of applications and robust nature position them as an invaluable asset in contemporary architecture and industry. Whether for enhancing structural beauty, improving functionality, or achieving environmental goals, the uses of these sheets are as diverse as they are essential.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP