Feb . 06, 2025 05:53

Back to list

0.8mm Perforated Metal Mesh Screen China Wholesalers Iron Perforated Sheet

The slotted hole perforated sheet is a versatile and specialized product widely acknowledged for its application across numerous industries. This article delves into the product’s nuances, demonstrating both its technical excellence and broad utility. Designed for those seeking depth and authority in slotted hole perforated sheet knowledge, the following insights are grounded in real-world experience and professional expertise.

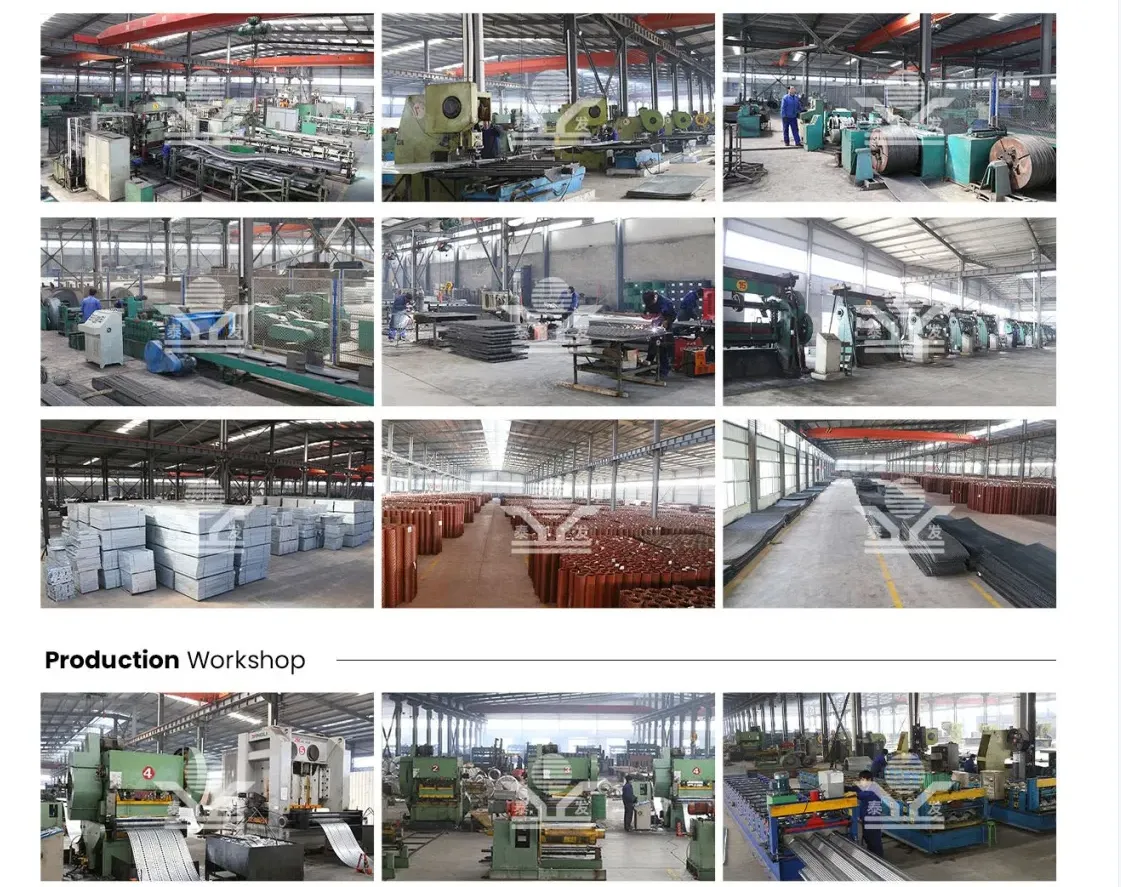

Manufacturing the slotted hole perforated sheet requires specialized expertise and state-of-the-art technology. The precision needed to produce these long slots is considerably higher than regular perforated sheets, confirming the necessity of experienced specialists in its production. Manufacturers involve in rigorous quality control processes to ensure each sheet meets stringent industry standards. This meticulous attention to detail guarantees that the sheets function optimally in all applications, which is a key concern for engineers and architects who depend heavily on material performance. Trust in the slotted hole perforated sheet also comes from ongoing research and development within the industry. Continuous advancements ensure that these products are at the forefront of material technology. Companies invest heavily in R&D to innovate better designs and materials, keeping them ahead in performance metrics that matter most to users. For anyone considering the slotted hole perforated sheet for their project, consulting with an industry expert is recommended. This step ensures that the specific requirements of your application are met and that the most suitable type and configuration of the sheet are selected. An expert will provide insights based on past applications, offering a realistic preview of its functionality and compatibility with other materials. In conclusion, the slotted hole perforated sheet is a multifaceted product that meets the demands of various high-performance environments. Its real-world applications testify to its superiority over traditional perforated materials, offering unparalleled advantages in sound management, airflow capability, and design aesthetics. As with any sophisticated product, its successful application hinges on expert knowledge and precision manufacturing, ensuring that it not only meets but exceeds expectations in a multitude of industrial and architectural domains.

Manufacturing the slotted hole perforated sheet requires specialized expertise and state-of-the-art technology. The precision needed to produce these long slots is considerably higher than regular perforated sheets, confirming the necessity of experienced specialists in its production. Manufacturers involve in rigorous quality control processes to ensure each sheet meets stringent industry standards. This meticulous attention to detail guarantees that the sheets function optimally in all applications, which is a key concern for engineers and architects who depend heavily on material performance. Trust in the slotted hole perforated sheet also comes from ongoing research and development within the industry. Continuous advancements ensure that these products are at the forefront of material technology. Companies invest heavily in R&D to innovate better designs and materials, keeping them ahead in performance metrics that matter most to users. For anyone considering the slotted hole perforated sheet for their project, consulting with an industry expert is recommended. This step ensures that the specific requirements of your application are met and that the most suitable type and configuration of the sheet are selected. An expert will provide insights based on past applications, offering a realistic preview of its functionality and compatibility with other materials. In conclusion, the slotted hole perforated sheet is a multifaceted product that meets the demands of various high-performance environments. Its real-world applications testify to its superiority over traditional perforated materials, offering unparalleled advantages in sound management, airflow capability, and design aesthetics. As with any sophisticated product, its successful application hinges on expert knowledge and precision manufacturing, ensuring that it not only meets but exceeds expectations in a multitude of industrial and architectural domains.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP