Exploring Serrated Gratings Optical Innovations and Applications

Serrated gratings are innovative optical devices characterized by their unique surface structures, which feature a series of parallel grooves or ridges with sharp, serrated edges. These structures are employed across various fields, including telecommunications, spectroscopy, and laser technology. This article delves into the principles behind serrated gratings, their manufacturing processes, and the myriad applications they serve.

The Principles of Serrated Gratings

At the core of serrated gratings lies the phenomenon of diffraction. When light encounters a grating, it scatters in various directions depending on its wavelength and the grating's characteristics. Serrated gratings enhance this diffraction process by creating a larger effective surface area through their serrated edges. The sharp features of the grating allow for increased interaction between light waves and the material, resulting in more efficient light manipulation.

The angular dispersion of light produced by serrated gratings is critical. When a polychromatic light source, such as white light, passes through the grating, different wavelengths are diffracted at distinct angles. This property is exploited in spectroscopic applications to separate light into its constituent colors, thereby providing essential data for analysis in scientific research and industrial settings.

Manufacturing Serrated Gratings

Creating serrated gratings involves advanced fabrication techniques that ensure precision and durability

. Common methods include photolithography, electron-beam lithography, and laser micromachining.1. Photolithography This method uses light to transfer a pattern onto a photosensitive material. The desired serration pattern is etched into the material, which is then developed to reveal the grooves.

2. Electron-Beam Lithography In this technique, a focused beam of electrons is used to create nanometer-scale patterns on the substrate. This method offers high-resolution features, making it suitable for applications requiring intricate designs.

3. Laser Micromachining This involves using lasers to precisely cut or engrave the serrated patterns onto various materials. This technique is advantageous for its speed and ability to work with different substrates, including metals and polymers.

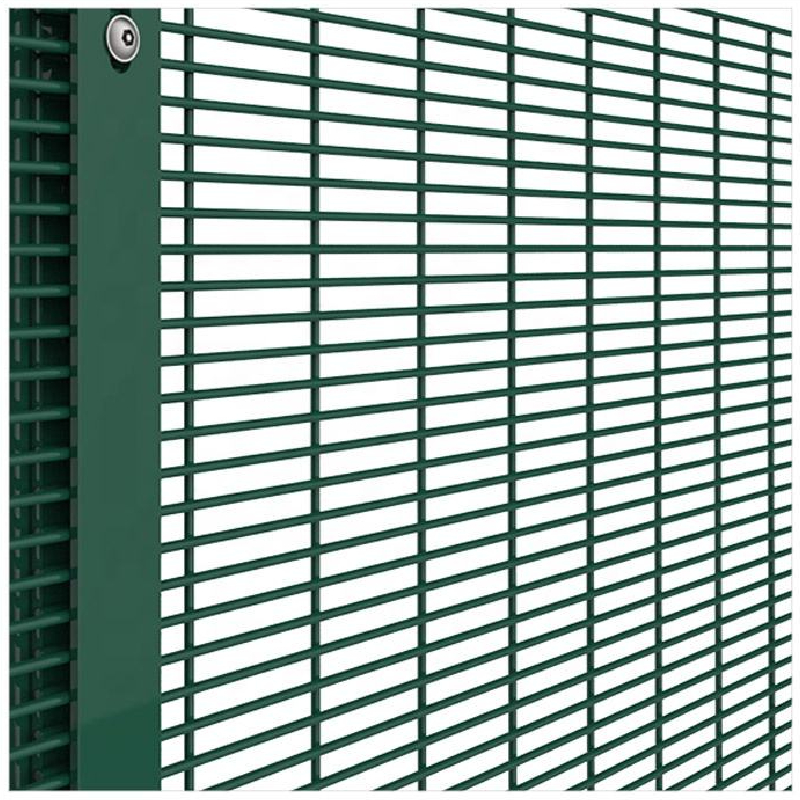

serrated grating

By utilizing these advanced manufacturing processes, researchers can create serrated gratings with various characteristics, such as differing serration depths and spacings, tailored for specific applications.

Applications of Serrated Gratings

The applications of serrated gratings are vast and span various sectors

1. Telecommunications Serrated gratings are essential in wavelength division multiplexing (WDM) systems, where multiple signals are transmitted over a single optical fiber. The gratings help effectively separate these signals, minimizing interference and enhancing data transmission rates.

2. Spectroscopy In scientific research, serrated gratings play a critical role in spectrometers, where they are used to analyze the spectrum of light emitted or absorbed by substances. Their high efficiency and ability to produce sharp spectral lines make them invaluable in chemical analysis, environmental monitoring, and material science.

3. Laser Systems Serrated gratings are utilized in various laser applications, including wavelength tuning and beam shaping. By manipulating the light output, they improve laser performance in medical devices, industrial cutting tools, and research laboratories.

4. Optical Sensors Serrated gratings also find applications in optical sensors, where they enhance the sensitivity and accuracy of measurements by increasing light interaction.

Conclusion

Serrated gratings represent a significant advancement in optical technology, allowing for enhanced light manipulation and a wide range of applications across different fields. As research progresses and manufacturing techniques continue to evolve, the capabilities and efficiencies of serrated gratings are expected to expand, paving the way for innovative applications and solutions. Whether in telecommunications, scientific research, or industrial applications, serrated gratings are transforming the landscape of modern optics, promising exciting developments in the years to come.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.