Feb . 12, 2025 19:08

Back to list

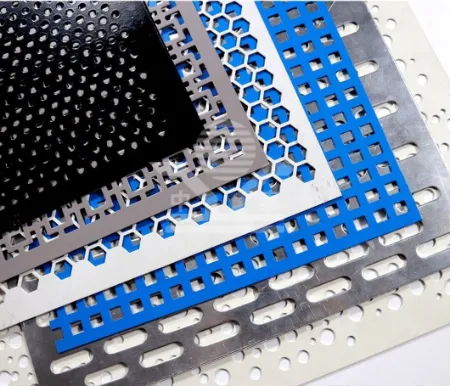

round perforated metal

Round perforated metal has become an indispensable material across various industries due to its versatility, efficiency, and functional aesthetics. It stands as a testament to engineering ingenuity, a material crafted meticulously to deliver performance while adding aesthetic value. This article delves into the various facets of round perforated metal, exploring its applications, advantages, and the expert insights into choosing the right product for specific needs.

Selecting the right round perforated metal also demands a keen insight into the coating and finishing processes. Galvanization, powder coating, and anodizing are some of the techniques that enhance the metal's resistance to environmental factors while offering various color options. These finishes not only prolong the metal’s life but also align with specific project aesthetics and functional requirements. It is imperative to source round perforated metal from reputable manufacturers who adhere to precise engineering standards and quality inspections. This ensures that the metal sheets meet the expected performance criteria and comply with industry safety regulations. Collaborating with experts in the field can further enhance the decision-making process, providing insights into the latest technological advancements and material innovations. Those keen on leveraging round perforated metal in their projects should also consider its recyclability. As sustainability becomes a pivotal consideration in modern engineering and design practices, the eco-friendly attributes of perforated metals add another layer of appeal. The material is 100% recyclable, and its production process has a relatively low environmental footprint compared to other materials. Feedback from professionals who have employed round perforated metal in their projects often highlights its ease of installation and the flexibility it offers in design alterations. Unlike monolithic materials, perforated metal allows for on-site adjustments without the need for extensive re-manufacturing, thus offering savings in both time and resources. In conclusion, the application of round perforated metal transcends beyond mere functional usage, evolving into a material that embodies modernity, sustainability, and innovation. Its ability to seamlessly integrate into varied environments and fulfill diverse roles speaks to its enduring utility. As industries continue to evolve and demand more sustainable, aesthetically pleasing, and efficient materials, round perforated metal remains a premier choice for engineers, architects, and designers worldwide. Exploring its potential could unlock new realms of design possibilities and engineering achievements, reaffirming its status as a cornerstone material in both contemporary and future applications.

Selecting the right round perforated metal also demands a keen insight into the coating and finishing processes. Galvanization, powder coating, and anodizing are some of the techniques that enhance the metal's resistance to environmental factors while offering various color options. These finishes not only prolong the metal’s life but also align with specific project aesthetics and functional requirements. It is imperative to source round perforated metal from reputable manufacturers who adhere to precise engineering standards and quality inspections. This ensures that the metal sheets meet the expected performance criteria and comply with industry safety regulations. Collaborating with experts in the field can further enhance the decision-making process, providing insights into the latest technological advancements and material innovations. Those keen on leveraging round perforated metal in their projects should also consider its recyclability. As sustainability becomes a pivotal consideration in modern engineering and design practices, the eco-friendly attributes of perforated metals add another layer of appeal. The material is 100% recyclable, and its production process has a relatively low environmental footprint compared to other materials. Feedback from professionals who have employed round perforated metal in their projects often highlights its ease of installation and the flexibility it offers in design alterations. Unlike monolithic materials, perforated metal allows for on-site adjustments without the need for extensive re-manufacturing, thus offering savings in both time and resources. In conclusion, the application of round perforated metal transcends beyond mere functional usage, evolving into a material that embodies modernity, sustainability, and innovation. Its ability to seamlessly integrate into varied environments and fulfill diverse roles speaks to its enduring utility. As industries continue to evolve and demand more sustainable, aesthetically pleasing, and efficient materials, round perforated metal remains a premier choice for engineers, architects, and designers worldwide. Exploring its potential could unlock new realms of design possibilities and engineering achievements, reaffirming its status as a cornerstone material in both contemporary and future applications.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP