Understanding Round Hole Perforated Stainless Steel Sheets

Round hole perforated stainless steel sheets are increasingly becoming a popular choice in various industries and applications due to their unique combination of durability, aesthetics, and functionality. These sheets are characterized by a series of round holes punched through the metal, allowing for a lightweight yet strong structure ideal for a myriad of uses.

The Manufacturing Process

The production of round hole perforated stainless steel sheets starts with a flat sheet of stainless steel, which is then subjected to a process known as perforating. In this process, a specialized machine employs a punch and die mechanism to create evenly spaced round holes across the sheet. These holes can vary in size, spacing, and pattern, allowing manufacturers to tailor the sheets to specific requirements.

Once the perforation is complete, the sheets undergo various finishing processes, such as polishing or anodizing. This enhances their aesthetic appeal while also adding protective layers against corrosion and wear, a critical aspect for stainless steel applications.

Material Properties

Stainless steel is renowned for its resistance to rust and corrosion, making it an ideal choice for perforated sheets used in environments exposed to moisture or chemicals. The most common grades of stainless steel used in perforation include 304 and 316. Grade 304 is versatile, easy to weld, and resistant to oxidation, while grade 316 offers superior corrosion resistance, particularly in marine environments.

Moreover, the mechanical strength of stainless steel ensures that the perforated sheets maintain their structural integrity even when subjected to heavy loads. This durability, combined with its lightweight nature, offers advantages in various construction and manufacturing sectors.

Applications of Round Hole Perforated Stainless Steel Sheets

The applications of round hole perforated stainless steel sheets are diverse and span numerous industries

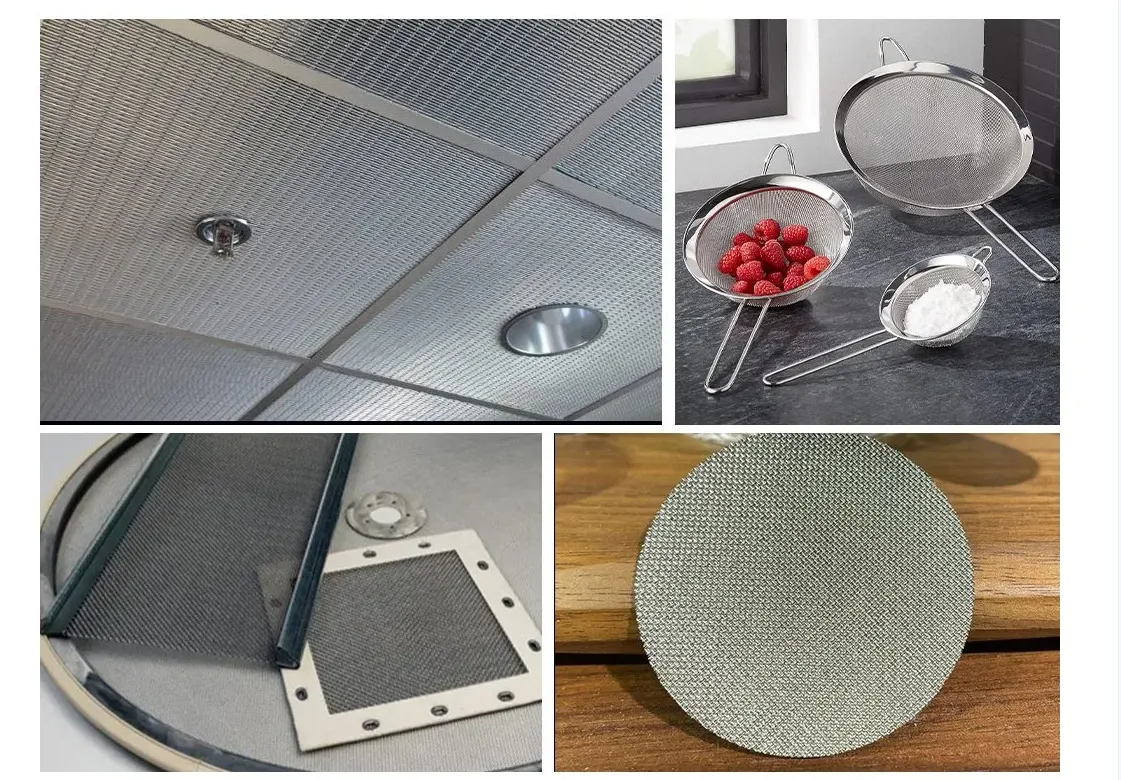

1. Architectural Features In modern architecture, perforated stainless steel is used for cladding on buildings, allowing for light and air to flow while providing a visually appealing facade. The round holes create unique patterns that can enhance the aesthetics of any structure, offering both beauty and functionality.

round hole perforated stainless steel sheet

2. Filtration Perforated sheets serve as excellent filters in various industrial processes. The precise sizing of the holes allows for the separation of liquids and solids, making these sheets essential components in chemical processing, food and beverage production, and wastewater treatment facilities.

3. Signage The use of perforated stainless steel in signage is popular as it allows for backlighting to shine through the holes, creating illuminated effects that are both striking and readable. This use is particularly prominent in commercial and advertising environments.

4. Sound Dampening Round hole perforated sheets can also be used in acoustic panels. The holes help in absorbing sound, making them ideal for use in theaters, concert halls, and other venues where sound control is paramount.

5. Safety and Security In applications requiring barriers or guards, perforated stainless steel sheets provide visibility while maintaining security. They are commonly used in fencing, machine guards, and safety grilles.

Advantages of Using Round Hole Perforated Stainless Steel Sheets

The benefits of using round hole perforated stainless steel sheets extend beyond just their functional properties. Key advantages include

- Versatility With numerous hole sizes and configurations available, these sheets can be customized for specific applications and aesthetic preferences. - Affordability Although stainless steel may have a higher upfront cost compared to other materials, its longevity and reduced need for maintenance often result in cost savings over time.

- Eco-friendliness Stainless steel is 100% recyclable, contributing positively to sustainability efforts and reducing environmental impact.

- Ease of Fabrication Perforated sheets are easily cut, shaped, and joined, allowing for creative designs and modifications to suit various projects.

Conclusion

Round hole perforated stainless steel sheets seamlessly blend functionality with aesthetics, making them an ideal choice for a wide range of applications. From architectural marvels to industrial processes, their versatility and durability ensure they will continue to play an essential role in engineering and design. As industries continue to evolve, the demand for such innovative materials will undoubtedly grow, paving the way for future advancements in technology and manufacturing.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.