Understanding Round Hole Perforated Sheets Applications and Benefits

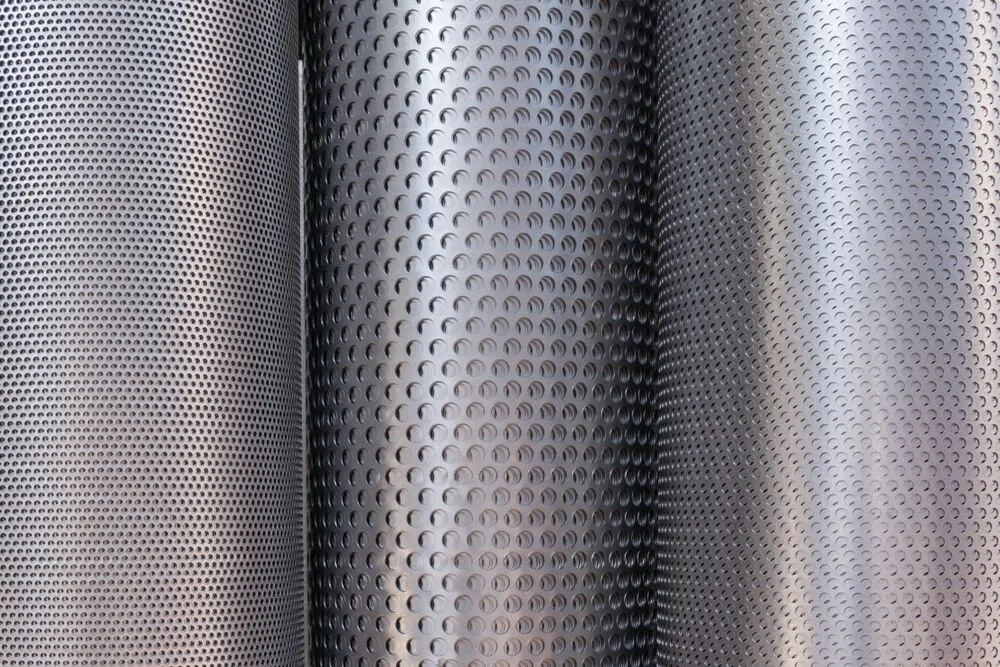

Round hole perforated sheets have gained immense popularity in various industries due to their unique attributes and versatility. Comprising a flat sheet of material such as metal, plastic, or fiberglass, these sheets are punctured with a series of uniformly sized holes, typically circular in shape. This article delves into the characteristics, applications, and advantages of round hole perforated sheets.

Characteristics of Round Hole Perforated Sheets

The design of round hole perforated sheets is not merely for aesthetics; it serves numerous functional purposes. The diameter, spacing, and arrangement of the holes can be customized according to requirements, providing a wide range of options. Typically made from materials like steel, aluminum, stainless steel, or polycarbonate, these sheets are durable and capable of withstanding harsh environments, making them suitable for both indoor and outdoor applications.

The hole sizes can vary significantly, ranging from tiny pinholes to larger openings capable of accommodating airflow or material flow. The sheet's thickness and hole pattern contribute to its strength, weight, and flexibility, allowing it to perform efficiently across various uses.

Applications of Round Hole Perforated Sheets

Round hole perforated sheets are utilized in numerous industries, demonstrating remarkable flexibility and adaptability

. Below are some prime applications1. Architecture and Interior Design In architecture, perforated sheets are often used in facades for sun shading, enhancing aesthetic appeal while providing functional benefits like reducing glare and controlling temperature. Inside buildings, they can be used as decorative panels, room dividers, or ceiling tiles, allowing for creativity while maintaining light flow.

2. Filtration and Ventilation These sheets play a vital role in filtration applications, where they serve as screens for separating fine particles from liquids or gases. Their design permits airflow while filtering out contaminants, making them ideal for air filters, water filters, and industrial filtration systems.

round hole perforated sheet

3. Sound Absorption and Acoustic Panels In sound engineering, round hole perforated sheets are used to create acoustic panels. The holes allow sound waves to penetrate and diffuse, helping to control sound levels in environments such as recording studios, theaters, and auditoriums.

4. Industrial Applications Many manufacturing and processing industries rely on round hole perforated sheets for various applications, including protective guards, conveyor systems, and shelving. They are used in machinery to create barriers while allowing for necessary airflow and visibility.

5. Transportation In the automotive and aerospace sectors, perforated sheets are found in components such as grilles, ventilation systems, and noise dampening devices, enhancing functionality while reducing weight.

Benefits of Using Round Hole Perforated Sheets

The advantages of opting for round hole perforated sheets are numerous. They offer excellent strength-to-weight ratios, which is crucial in applications where minimizing weight is essential without sacrificing durability. Additionally, their customizable nature allows businesses to get precise specifications that suit their needs.

Moreover, these sheets can improve the aesthetics of a project, providing a modern and stylish look while serving functional purposes. Maintenance is also relatively simple; most surfaces are easy to clean and resistant to corrosion, prolonging their lifespan in various environments.

Conclusion

Round hole perforated sheets represent an intersection of functional design and versatile application across industries. Whether used for construction, filtration, acoustics, or industrial purposes, their adaptability and benefits make them a favored choice among engineers, architects, and manufacturers. As industries continue to evolve and seek innovative solutions, the relevance of round hole perforated sheets remains undiminished, proving that this simple design can meet complex challenges efficiently.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.