Round Hole Perforated Metal Applications, Benefits, and Manufacturing Processes

Perforated metal, characterized by a pattern of holes punched into its surface, has gained substantial popularity across various industries due to its versatility, functionality, and aesthetic appeal. Among the many designs available, round hole perforated metal stands out as a preferred choice for a multitude of applications, appealing to both industrial and decorative needs. This article delves into the features, benefits, applications, and manufacturing processes associated with round hole perforated metal.

Features of Round Hole Perforated Metal

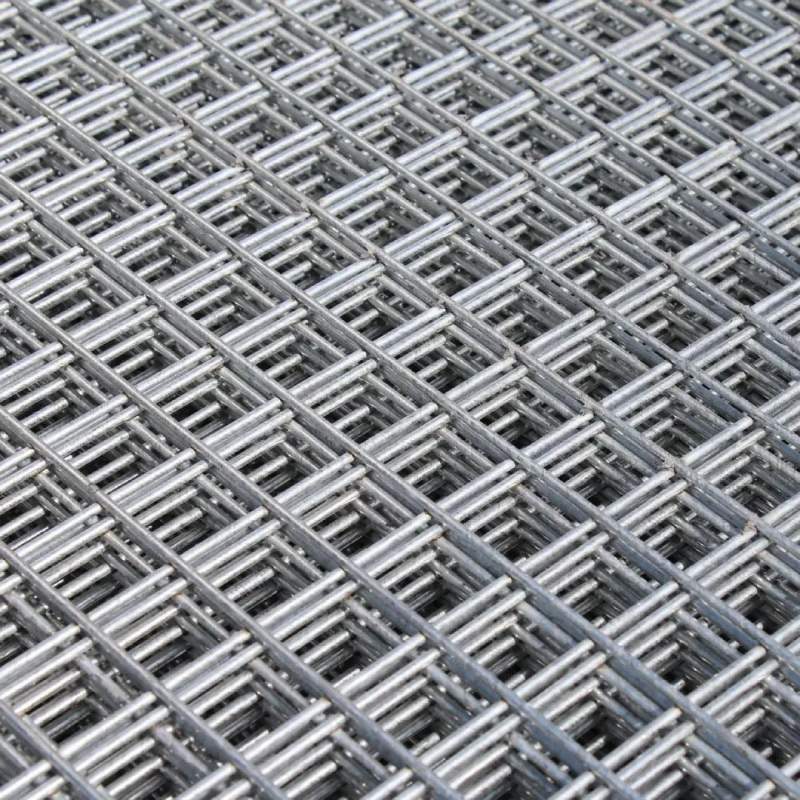

Round hole perforated metal sheets are produced by meticulously punching holes of uniform diameter into a solid metal sheet. This design can vary in hole size, spacing, and thickness, allowing for a wide range of custom configurations. The resulting product not only maintains the strength and stability of the original metal but also provides the added benefit of reduced weight. The round holes create a visually appealing pattern that can enhance the aesthetics of any structure, making it a popular choice for architectural applications.

Benefits of Using Round Hole Perforated Metal

1. Versatility Round hole perforated metal can be fabricated from various materials including stainless steel, aluminum, copper, and even plastic. This versatility allows it to be used in a myriad of settings, from industrial applications to decorative elements.

2. Enhanced Sound Absorption The holes in the perforated sheets allow sound waves to pass through, reducing noise levels. This property makes round hole perforated metal a valuable asset in acoustically sensitive environments, such as music venues, schools, and offices.

3. Weight Reduction Unlike solid metal sheets, perforated metal products are lighter due to the absence of material in the areas where holes have been punched. This reduction in weight can lead to easier handling and installation.

4. Increased Strength and Durability While being lighter, round hole perforated metal retains a significant amount of strength, making it suitable for carrying loads and enduring harsh conditions. This makes it ideal for applications where structural integrity is critical.

5. Aesthetic Appeal The uniform design of round holes can create striking visual effects, making it a popular choice for architectural facades, railings, and decorative panels. It adds a contemporary touch to various applications while maintaining a professional look.

Applications of Round Hole Perforated Metal

The applications of round hole perforated metal are vast and span various sectors

- Architectural Features Used in facades, interior partitions, and ceiling tiles, round hole perforated metal enhances building aesthetics while providing functional benefits such as light diffusion and ventilation.

round hole perforated metal

- Industrial Uses Commonly used in filter and screening applications, round hole perforated metal is effective for separating materials in industries like mining, agriculture, and food processing.

- Furniture Design Designers often incorporate round hole perforated metal in tables, chairs, and shelving units to add a modern look while maintaining functionality.

- Ventilation Systems The round holes facilitate airflow in HVAC systems, improving efficiency while minimizing noise levels.

- Art Installations Artists leverage the unique aesthetic properties of round hole perforated metal to create modern sculptures and installations, allowing light and space to interact in intriguing ways.

Manufacturing Process

The production of round hole perforated metal typically involves several steps

1. Material Selection The first step in manufacturing involves selecting the appropriate type of metal based on the intended application. Factors such as corrosion resistance, strength, and appearance are considered.

2. Punching Using specialized machines, round holes are punched into the metal sheets. This process can be programmed to create different hole sizes and configurations according to design specifications.

3. Finishing After punching, the perforated sheets may undergo various finishing processes, such as cleaning, polishing, or coating, to enhance appearance and increase resistance to environmental factors.

4. Quality Control The final steps typically involve rigorous quality checks to ensure that the perforated sheets meet specified standards for size, spacing, and overall integrity.

Conclusion

Round hole perforated metal is an incredibly versatile material that serves a multitude of functions across various industries. Its unique combination of practicality, durability, and aesthetic appeal makes it an indispensable choice for architects, designers, and engineers alike. As industries continue to evolve, the demand for innovative materials like round hole perforated metal will undoubtedly grow, leading to even more creative applications and designs. Whether for structural, functional, or decorative purposes, round hole perforated metal is set to remain a valuable resource in contemporary manufacturing and design.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.