Feb . 01, 2025 04:17

Back to list

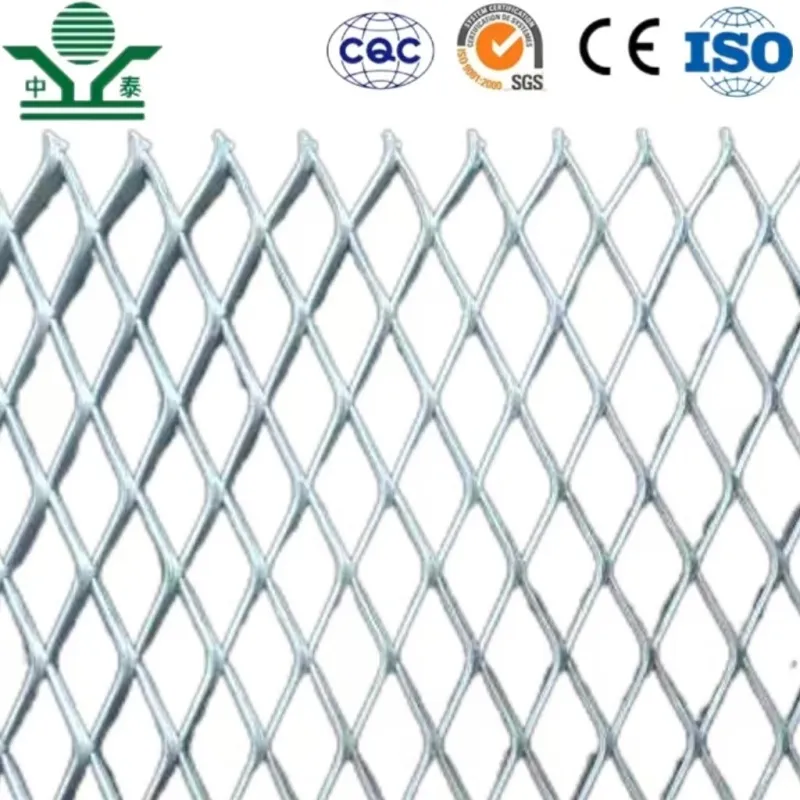

decorative punched metal sheets

Exploring the versatility of punched metal sheets reveals not only their functional capacity but also the range of applications they cover across various industries. These sheets, characterized by their aesthetic appeal and mechanical efficiency, have carved a niche in sectors such as architecture, automotive, agriculture, and beyond. A comprehensive understanding of punched metal sheets can transform everyday applications into innovative solutions.

Critical to the successful application of punched metal sheets is precision in their creation. Advanced machinery allows for exact hole placement and uniformity, crucial factors for maintaining strength and integrity in the final product. Attention to detail in the fabrication process reflects expertise and enhances trustworthiness, ensuring clients receive products that meet stringent quality standards. Authoritativeness in this field often derives from mastery over both the technical processes of manufacturing and the nuanced demands of different applications. Companies specializing in punched metal sheets typically employ skilled professionals with years of experience in metallurgy and industrial design. Their insights drive innovation, as they continually evolve designs and functionalities to suit emerging market needs. Trust in punched metal sheet products is built on proven performance and reliability. Case studies showcasing successful applications across various industries strengthen credibility and reassure potential customers. Transparency in sourcing, manufacturing processes, and quality control further enhances trust. In summary, punched metal sheets are far more than simple metal products. They represent a fusion of art and science, functionality and design. Their versatility, enhanced by industry expertise and authoritative manufacturing practices, confirms their irreplaceable role across sectors. Whether in high-profile architectural projects, everyday automotive components, or essential agricultural tools, punched metal sheets offer unparalleled value and innovation.

Critical to the successful application of punched metal sheets is precision in their creation. Advanced machinery allows for exact hole placement and uniformity, crucial factors for maintaining strength and integrity in the final product. Attention to detail in the fabrication process reflects expertise and enhances trustworthiness, ensuring clients receive products that meet stringent quality standards. Authoritativeness in this field often derives from mastery over both the technical processes of manufacturing and the nuanced demands of different applications. Companies specializing in punched metal sheets typically employ skilled professionals with years of experience in metallurgy and industrial design. Their insights drive innovation, as they continually evolve designs and functionalities to suit emerging market needs. Trust in punched metal sheet products is built on proven performance and reliability. Case studies showcasing successful applications across various industries strengthen credibility and reassure potential customers. Transparency in sourcing, manufacturing processes, and quality control further enhances trust. In summary, punched metal sheets are far more than simple metal products. They represent a fusion of art and science, functionality and design. Their versatility, enhanced by industry expertise and authoritative manufacturing practices, confirms their irreplaceable role across sectors. Whether in high-profile architectural projects, everyday automotive components, or essential agricultural tools, punched metal sheets offer unparalleled value and innovation.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP