The Versatility and Appeal of Powder Coated Perforated Metal Sheets

In the realm of modern architecture and interior design, the use of metal materials has evolved significantly, especially with the rise of powder coated perforated metal sheets. These sheets are not only functional but also beautiful, combining durability with aesthetic appeal. This article explores the characteristics, benefits, applications, and design flexibility of powder coated perforated metal sheets.

Understanding Powder Coating

Powder coating is a finishing process that involves the application of a dry powder to a surface, which is then cured under heat to create a uniform and tough finish. Unlike traditional liquid paint, powder coatings contain no solvents, making them environmentally friendly. They come in a wide range of colors and finishes, allowing designers and architects to select options that best fit their vision.

The process entails applying an electrostatically charged powder to the metal surface, which attracts the powder particles. Once the metal sheet is coated, it is heated in an oven, causing the powder to melt and bond to the surface. The result is a resilient coating that is resistant to chipping, scratching, and fading, ensuring that the appearance lasts over time.

Perforated Metal Sheets Functionality Meets Design

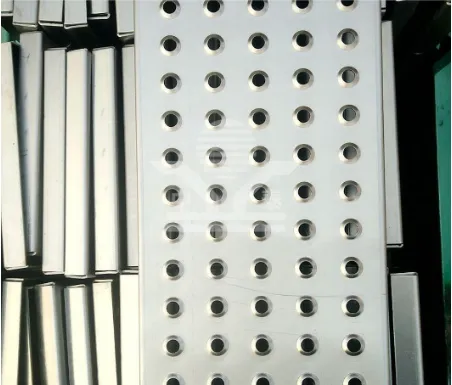

Perforated metal sheets are sheets that have been punctured with holes, creating a pattern that can serve both form and function. They are used to provide ventilation, reduce weight, and enhance appearance in countless applications. The arrangement and size of the holes can vary significantly, allowing for tailored designs suited to a variety of needs.

When combined with powder coating, perforated metal sheets achieve a distinct advantage in both aesthetics and performance. The coating protects the metal from corrosion and wear, while the perforations add visual intrigue and functional capability. Designers can achieve intricate patterns and designs, making these products ideal for both industrial and decorative applications.

Benefits of Powder Coated Perforated Metal Sheets

1. Durability The powder coating process provides an extra layer of protection, making these sheets resilient against environmental stressors such as moisture, UV rays, and chemicals. This longevity makes them suitable for both indoor and outdoor applications.

powder coated perforated metal sheet

2. Aesthetic Variety With an extensive palette of colors and finishes available, powder coated perforated metal sheets can complement any architectural style or interior design theme. This versatility is particularly valuable in projects where visual appeal is paramount.

3. Lightweight with Strength Perforated sheets are typically lighter than solid metal sheets, making them easier to handle and install without compromising on strength. This property is particularly beneficial in architectural projects that require strong but lightweight materials.

4. Acoustic Performance Perforation patterns can be designed to enhance acoustic performance, making these sheets a popular choice in environments where sound control is essential, such as auditoriums and office spaces.

5. Eco-Friendly The powder coating process is more environmentally friendly than traditional paint, producing less waste and using fewer chemicals. Additionally, metal is 100% recyclable, contributing to sustainable construction practices.

Applications Across Industries

The use of powder coated perforated metal sheets spans various industries and sectors. They are commonly found in architecture for facade cladding, sunshades, and decorative elements. In interiors, they are used for partitions, railings, and ceiling designs. They also find application in transportation, automotive, and furniture design, contributing to both function and style.

Further, in the industrial sector, these sheets are used for filtration systems, guards, and enclosures that require ventilation while maintaining safety and visibility. The adaptability of perforated sheets makes them suitable for customization, allowing designers to create unique solutions for specific project needs.

Conclusion

Powder coated perforated metal sheets embody the perfect blend of functionality and aesthetics. Their durable surface, design versatility, and range of applications render them an indispensable material in modern design and architecture. As industries continue to innovate and prioritize sustainability, these sheets stand out as a prime example of how engineering and creativity can converge to produce products that are not only practical but also visually captivating. Whether for a grand architectural project or a simple interior accent, powder coated perforated metal sheets offer endless possibilities.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.